Tightening device used for joint between steel plates during steel structure welding

A steel structure and steel plate technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as the influence of steel plate flatness, achieve low manufacturing costs, meet quality control and quality requirements, and improve work efficiency and welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

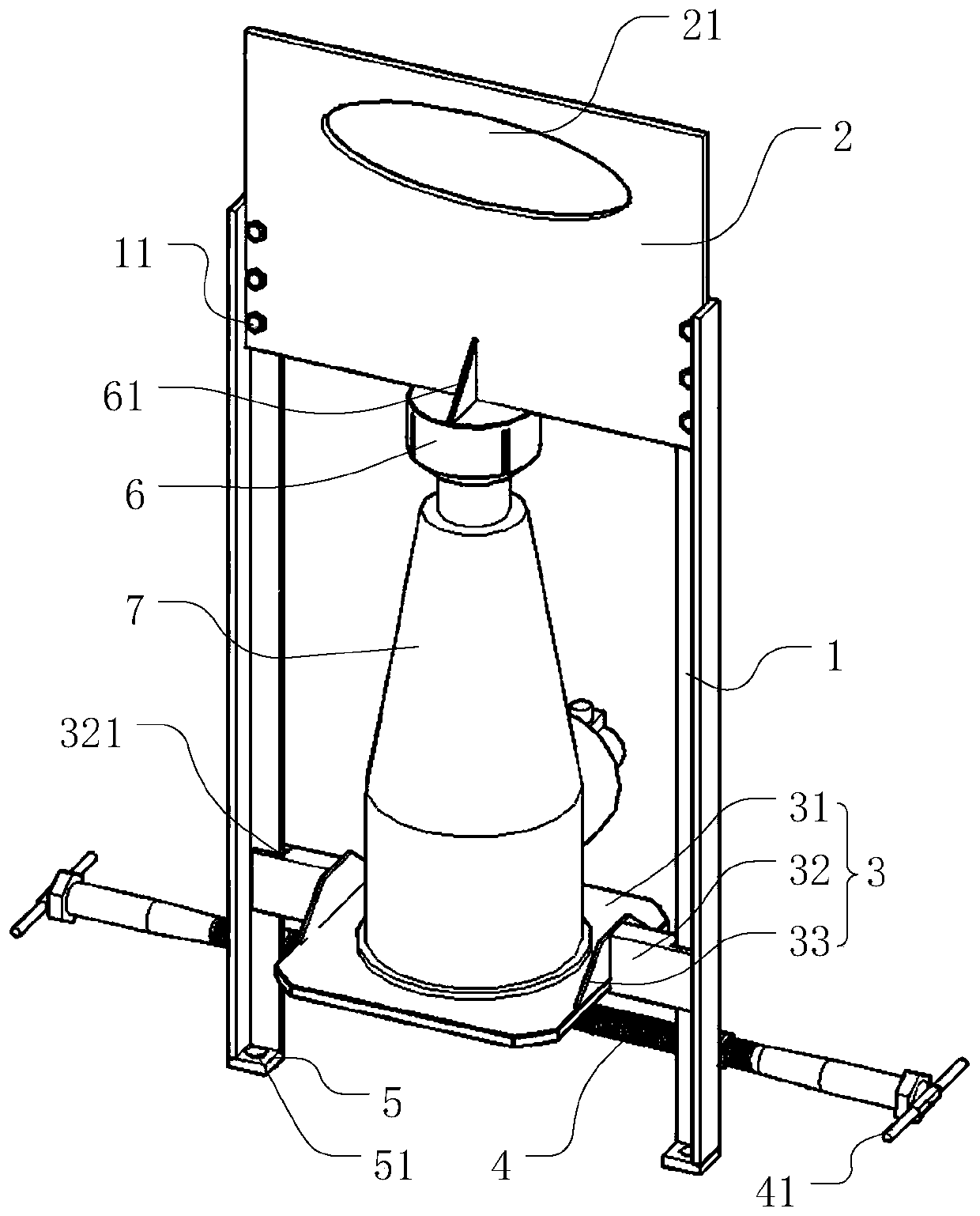

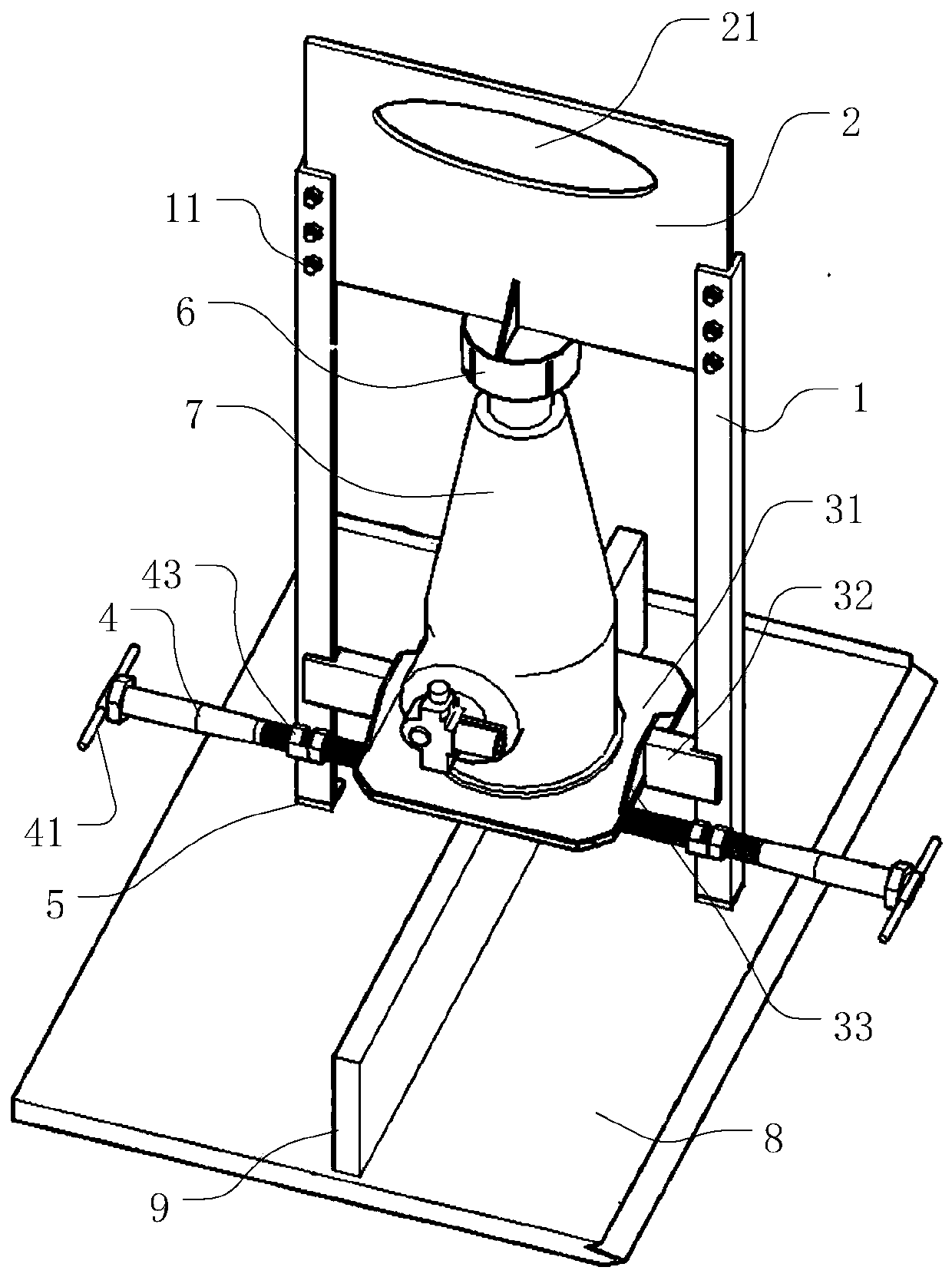

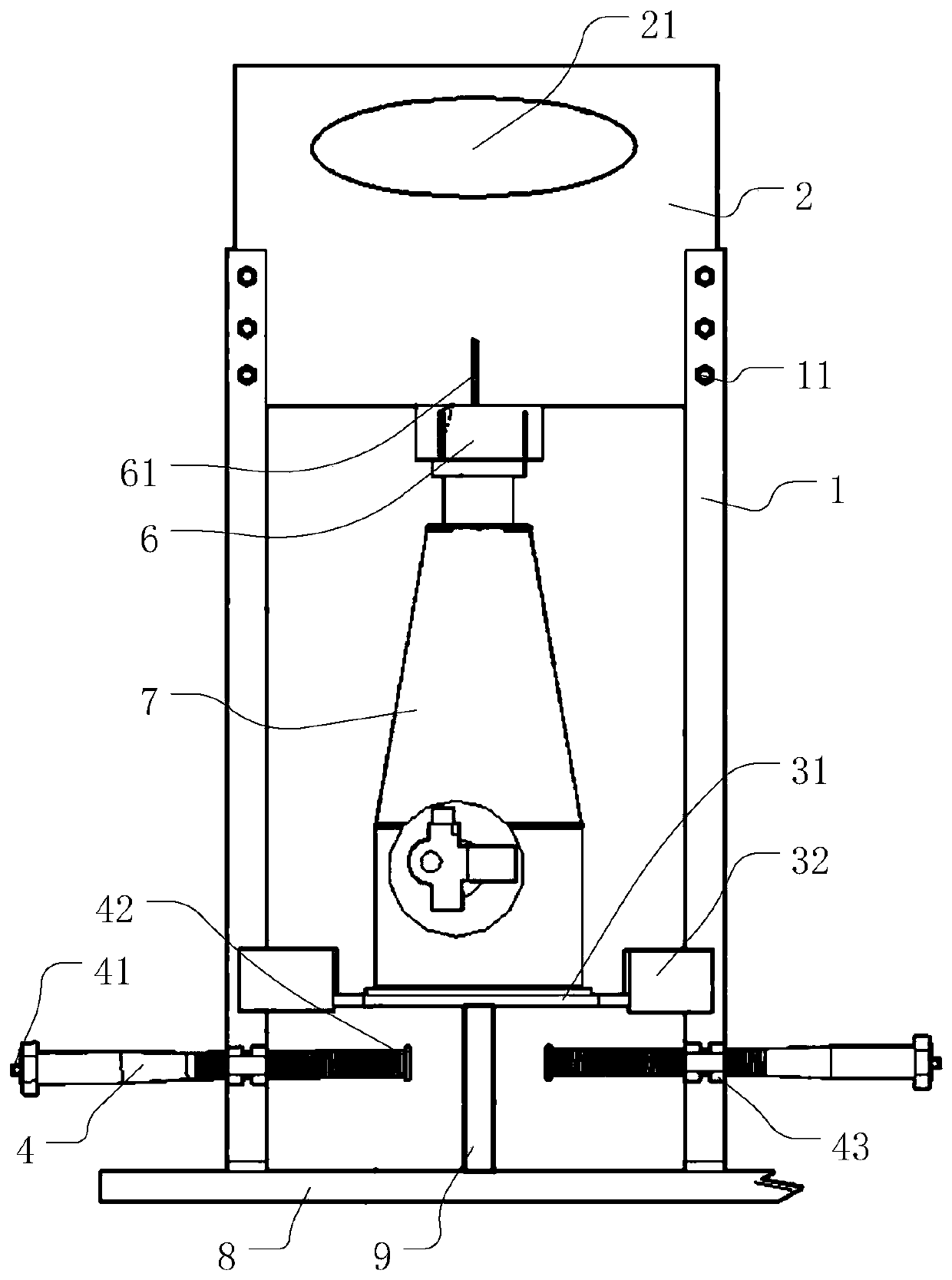

[0027] refer to Figure 1 to Figure 3 , a joint tightening device between steel plates when welding steel structures, the steel structure includes steel plates and ribs, the ribs are vertically welded on the steel plates, and the tightening device includes a portal frame, a pallet frame 3, a jack 7 and rib verticality adjustment mechanism. The gantry includes a space-limiting top plate 2 and two fixed legs 1 arranged in parallel, and the space-limiting top plate 2 is connected to the tops of the two fixed legs 1 . The tray frame 3 is arranged between the two fixed legs 1 and is slidably connected to the two fixed legs 1 along the vertical direction. The jack 7 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com