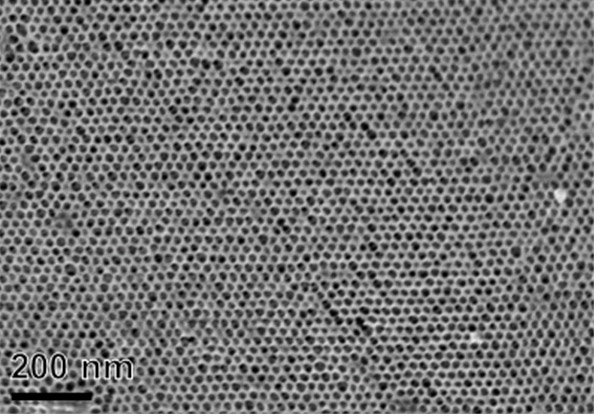

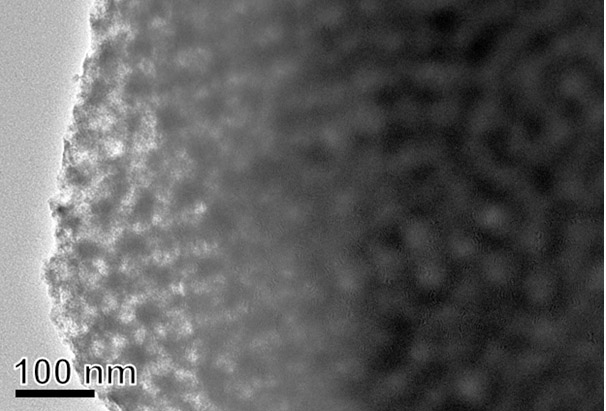

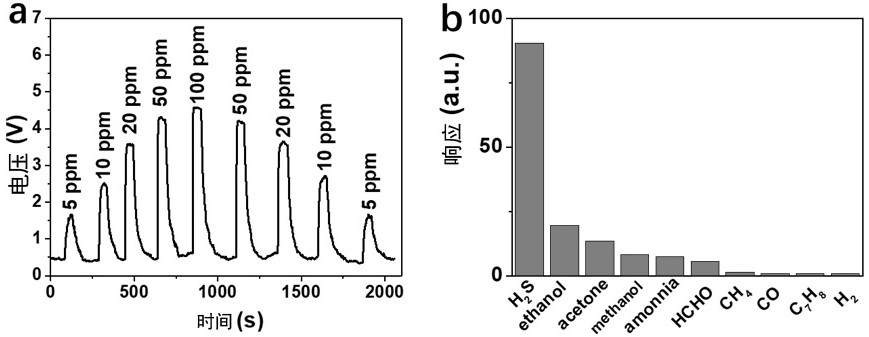

p-type semiconductor metal oxide doped ordered mesoporous tungsten oxide gas sensing material and preparation method thereof

A technology of gas-sensing materials and oxides, applied in the direction of nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, copper oxide/copper hydroxide, etc., can solve the influence of mesopore disorder, uncontrollable pore structure, Complicated synthesis steps and other problems, to achieve the effect suitable for scale-up production, good sensitivity and selectivity, simple and controllable steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) The amphiphilic block copolymer polyethylene oxide- b - Polystyrene (PEO 114 - b -PS 336 , M n =36948 gmol -1 ) was dissolved in tetrahydrofuran (THF) solution and stirred to obtain a uniform solution A (the mass percentage of the polymer was 2.0 wt%); anhydrous tungsten hexachloride (WCl) was added to ethanol 6 ) and acetylacetone (AcAc), stirred until the solid was completely dissolved to obtain a homogeneous solution B, A and B were mixed and stirred for 2 h, and the solution turned dark green. Add 2.0 mg of copper acetylacetonate (copper source) and stir for 10 min. The mass ratio of block copolymer: tetrahydrofuran: ethanol: anhydrous tungsten hexachloride: acetylacetone: copper source is 0.1:5:1:0.4:0.4:0.02;

[0026] (2) The solution was transferred to a petri dish with a diameter of 15 cm, volatilized at 25 °C for 1 h, and turned into a dark blue film. The petri dish was transferred to a 40 °C oven for 48 h to further evaporate the solvent, and then tr...

Embodiment 2

[0029] (1) The amphiphilic block copolymer polyethylene oxide- b - Polystyrene (PEO 108 - b -PS 112 , Mn=16689 gmol -1 ) in chloroform (CHCl) 3 ) solution, stir to obtain a uniform solution A (the mass percentage of the polymer is 2.0 wt%); add anhydrous tungsten hexachloride (WCl 6 ) and acetylacetone (AcAc), stirred until the solid was completely dissolved to obtain a homogeneous solution B, A and B were mixed and stirred for 2 h, and the solution turned dark green. Add nickel acetylacetonate (nickel source) and stir for 10 min. The mass ratio of block copolymer: chloroform: ethanol: anhydrous tungsten hexachloride: acetylacetone: nickel source is 0.1:5:1:0.4:0.4:0.02;

[0030] (2) The solution was coated on a quartz substrate by spin-coating, volatilized at 25 °C for 2 h to become a dark blue film, transferred to a 70 °C oven for 24 h to further evaporate the solvent, and then transferred Cured at 150 °C for 24 h to obtain a brown composite film;

[0031] (3) The fr...

Embodiment 3

[0033] (1) The amphiphilic block copolymer poly-(4-vinylpyridine)- b - Polystyrene (P4VP 76 - b -PS 96 , Mn≈18000 g mol -1 ) in dichloromethane (CH 2 Cl 2 ) solution, stir to obtain a uniform solution A (the mass percentage of the polymer is 2.0 wt%); add anhydrous tungsten hexachloride (WCl 6 ) and acetylacetone (AcAc), stirred until the solid was completely dissolved to obtain a homogeneous solution B, A and B were mixed and stirred for 2 h, and the solution turned dark green. Add cobalt(II) acetylacetonate (cobalt source) and stir for 10 min. The block copolymer: dichloromethane: ethanol: anhydrous tungsten hexachloride: acetylacetone: cobalt source mass ratio of 0.1:5:1:0.4:0.4:0.02;

[0034] (2) The solution was coated on a quartz substrate by a dip-coating method, volatilized at 25 °C for 1 h, and turned into a dark blue film, which was transferred to a 40 °C oven for 24 h to further evaporate the solvent, and then transferred Cured at 100 °C for 24 h to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com