Heat-supply heating well overground structure

A technology for heating wells and high-temperature heating, applied in the field of geothermal heating, can solve the problems of low calorific value, affect groundwater, high maintenance costs, etc., and achieve the effect of improving heat capacity and maximizing thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

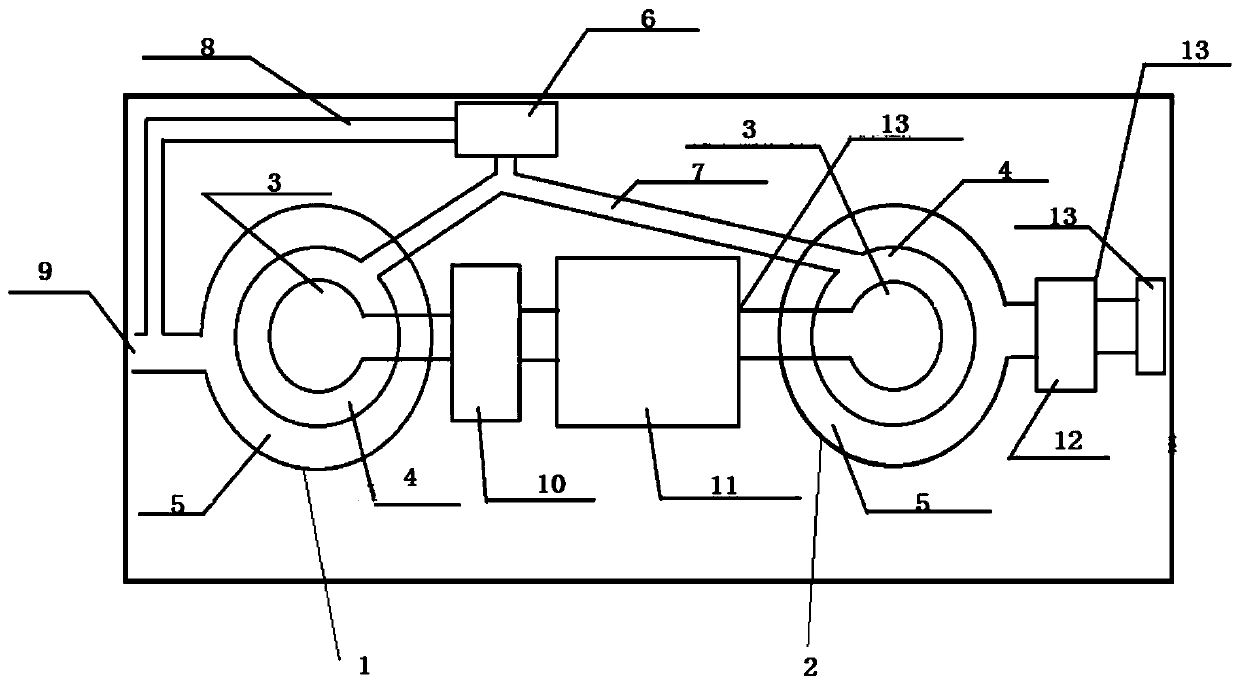

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] In the process of drilling and completion, in order to separate different geological formations and prevent the well wall from collapsing due to different formation pressures, one or more layers of casing are required for cementing, and each layer of casing is cemented with cement. The space is filled with annulus protection fluid, and the pressure of the annular space between the casings of each layer is the annular pressure, which is generally called A annulus, B annulus, C annulus, etc., because there may be natural gas or Annulus protection fluid, affected by the temperature during production, expands with heat and contracts with cold, resulting in pressure. Annular pressure control is very important in the development of high-yield and high-pressure natural gas wells. Ultra-high annular pressure may cause casing rupture and natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com