Hub bearing unit and stop ring

A technology of wheel hub bearing and snap ring, applied in the field of machinery, can solve problems such as interference between snap ring and shaft tube, and achieve the effects of reducing machining depth, improving structural strength, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It can be seen from the background technology that the current hub bearing unit has the problem of interference between the stop ring and the axle tube.

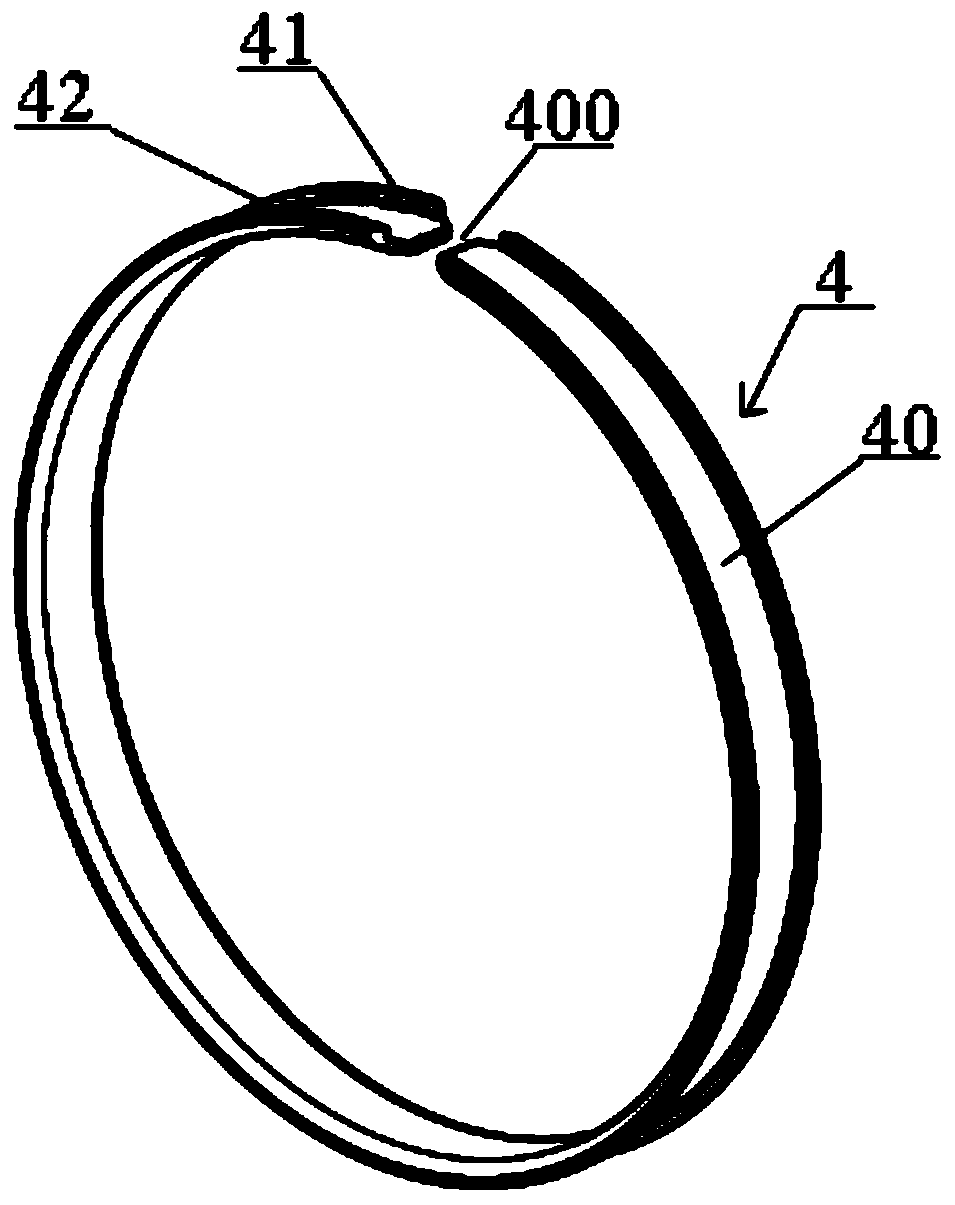

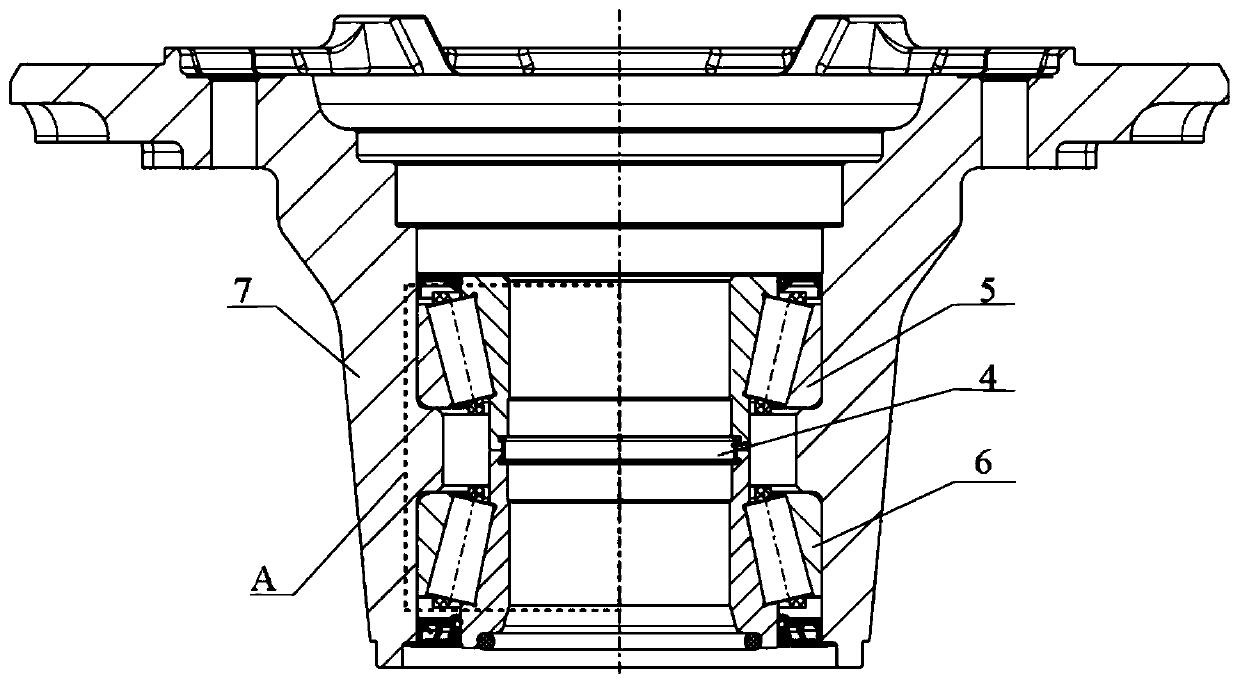

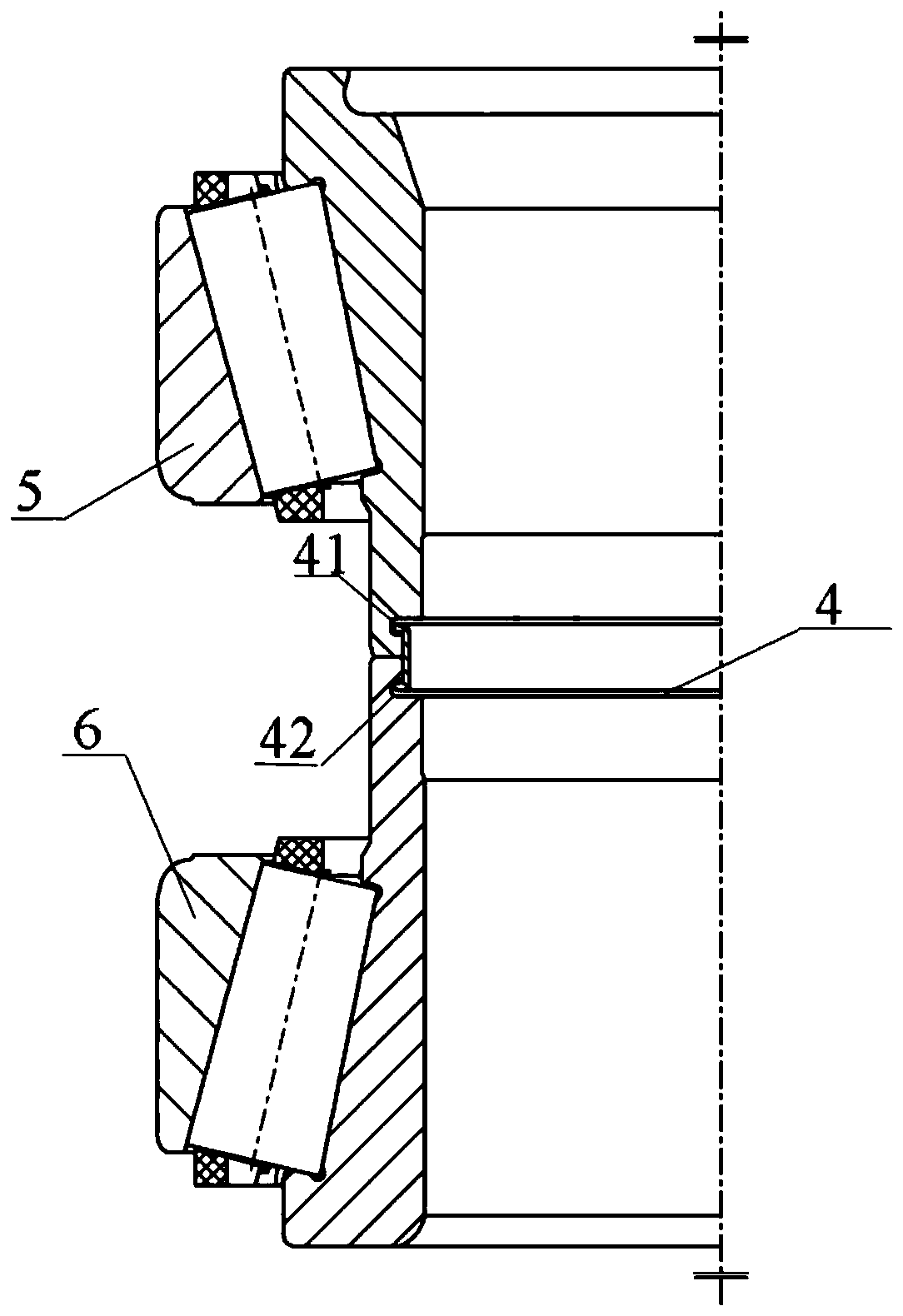

[0038] Please refer to Figure 1-Figure 3 , figure 1 is a structural schematic diagram of a stop ring; figure 2 is a sectional view of a hub bearing unit; image 3 yes figure 2 Partial enlarged schematic diagram of region A in middle.

[0039] As shown in the figure, a hub bearing unit includes: a first bearing 5 , a second bearing 6 , a stop ring 4 and a hub 7 .

[0040] When assembling, the outer rings of the first bearing 5 and the second bearing 6 are pressed into the hub successively, and then the inner ring support tool of the first bearing 5 is installed on the workbench, and the inner components of the first bearing (inner ring, roller and cage) on the tooling, and then insert the hub 7 that has been press-fitted with the outer ring, then put the second bearing inner assembly, and finally place the stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com