Gear and method of making the same

A manufacturing method and technology of gears, applied in the directions of belts/chains/gears, gear teeth, components with teeth, etc., can solve problems such as stress increase and damage, and achieve the effect of improving long-term durability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

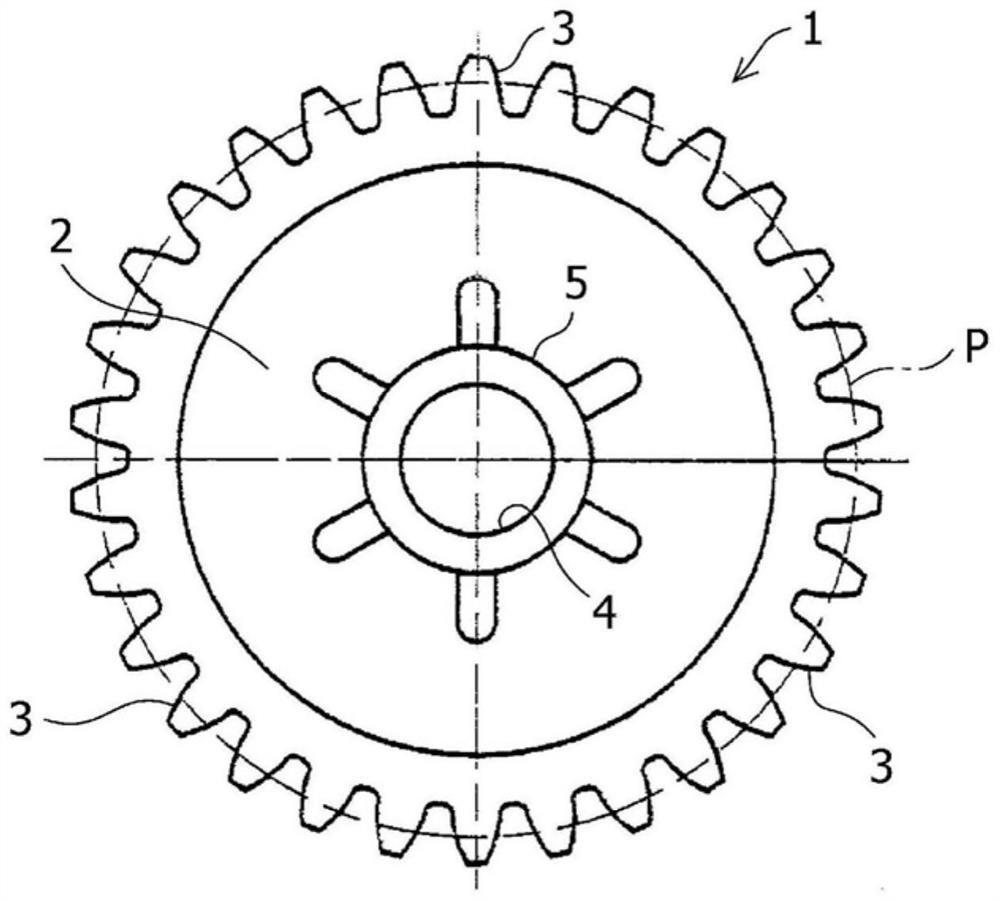

[0058] figure 1 It is a front view which shows the whole shape of the gear of this invention. The gear has a plurality of teeth, and is used for transmission of rotational motion between two shafts by meshing with the teeth of the opposite gear.

[0059] exist figure 1In the gear 1, a plurality of teeth 3, 3, . . . are formed on the outer peripheral side of a substantially disc-shaped web 2, and a boss 5 is formed in the center of the web 2, and the boss 5 is provided with a rotating The shaft hole 4 on which the shaft is fixed transmits rotational motion between the two shafts. In addition, the symbol P represents the pitch circle of the gear 1 .

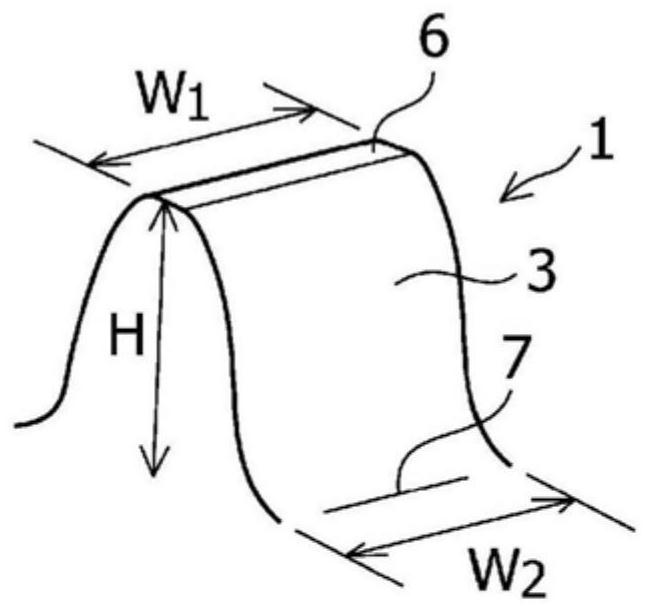

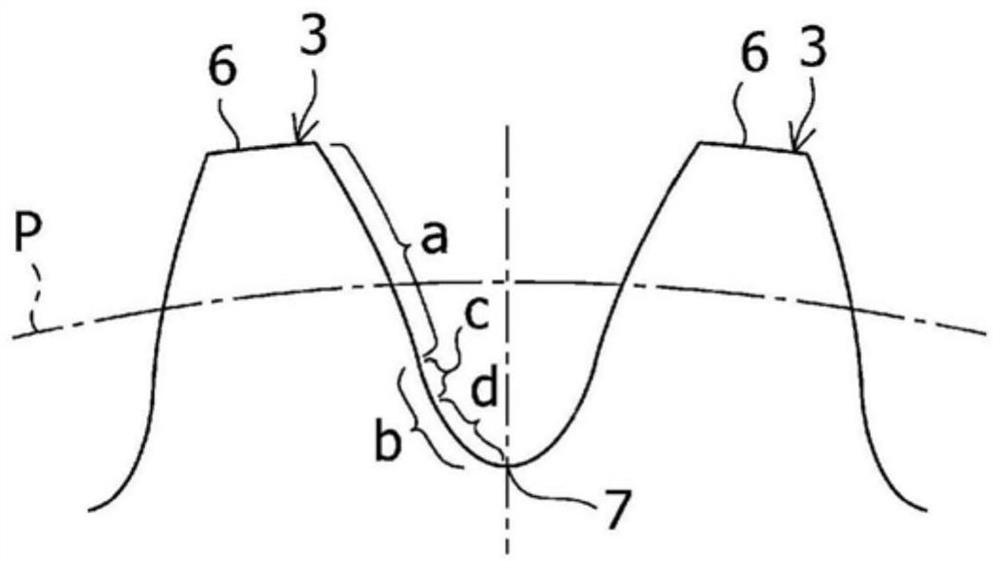

[0060] Generally as figure 2 As shown, the teeth 3 of the gear 1 are formed into the tooth profile of a standard gear which has an involute curve tooth surface and is bilaterally symmetrical. That is, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com