A support structure of a microstructured gas detector and its preparation method

A gas detector and supporting structure technology, which is applied to the structural details of gas analyzers, analysis of gas mixtures, instruments, etc., can solve the problems of low accuracy, difficulty in ignition and discharge of detectors, and low efficiency, so as to improve processing accuracy, Improve the efficiency and accuracy of placement, and the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

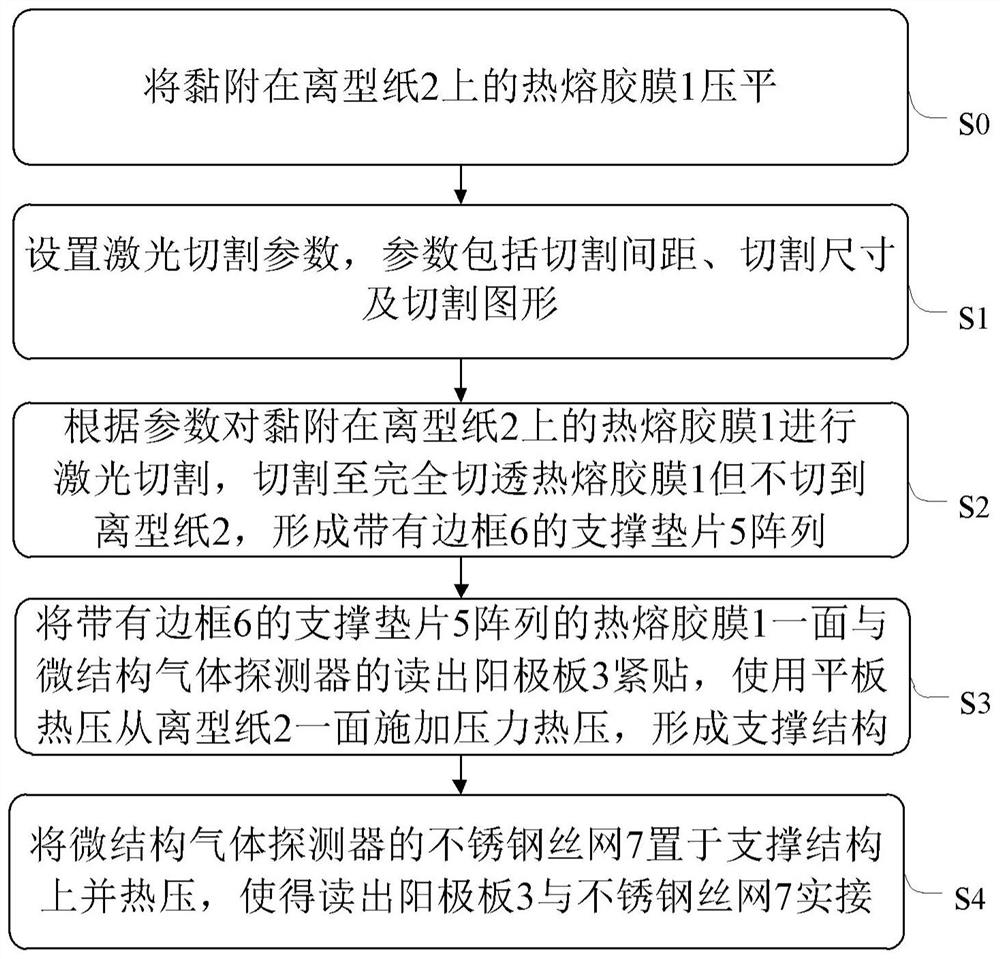

[0041] The present invention proposes a method for preparing a support structure of a microstructured gas detector, the specific process of which is as follows figure 1 shown, including:

[0042] S0, flatten the hot melt adhesive film 1 attached to the release paper 2 .

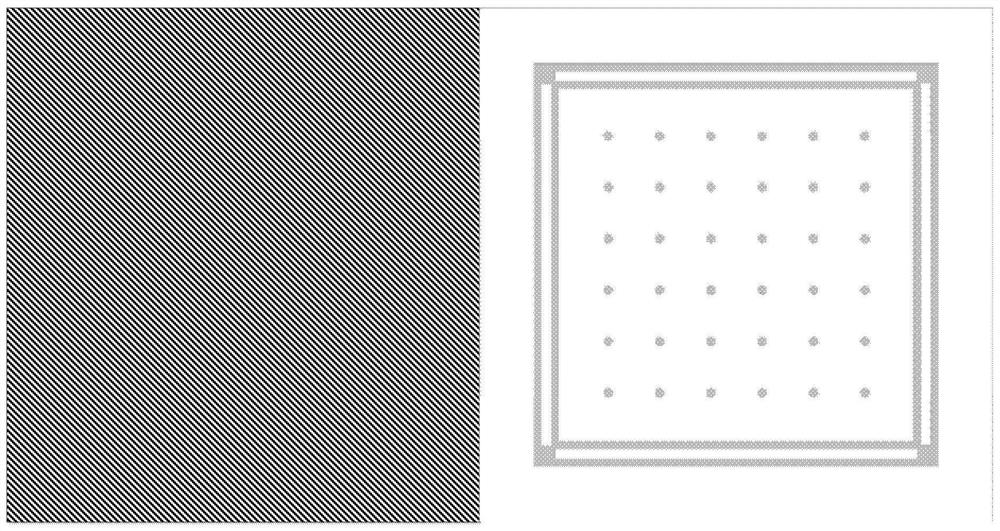

[0043] In one embodiment of the present invention, the hot-melt adhesive film 1 used is adhered to the silicone release paper 2 and is in the shape of a roll. Therefore, before laser cutting, at first, the hot-melt adhesive film 1 is cut into small pieces as required and Flatten it by applying pressure, such as figure 2 shown. Secondly, use adhesive tape to fix the release paper 2 with the hot melt adhesive film 1 on the laser cutting platform. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com