Method for preparing bistable dimming device and bistable dimming device

A bistable, device technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of increasing the complexity and difficulty of the production process, limiting the application of dimming devices, and increasing the production cost, so as to improve the yield and simplify the production. Preparation process, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

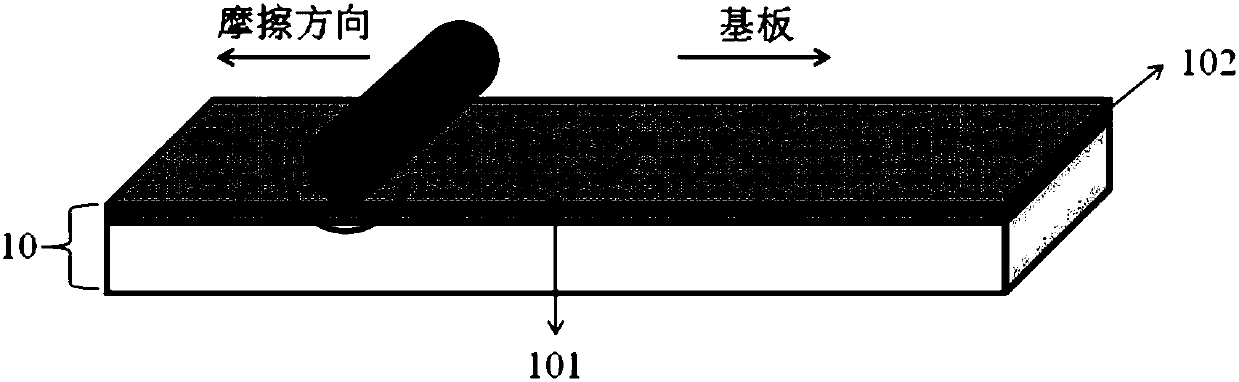

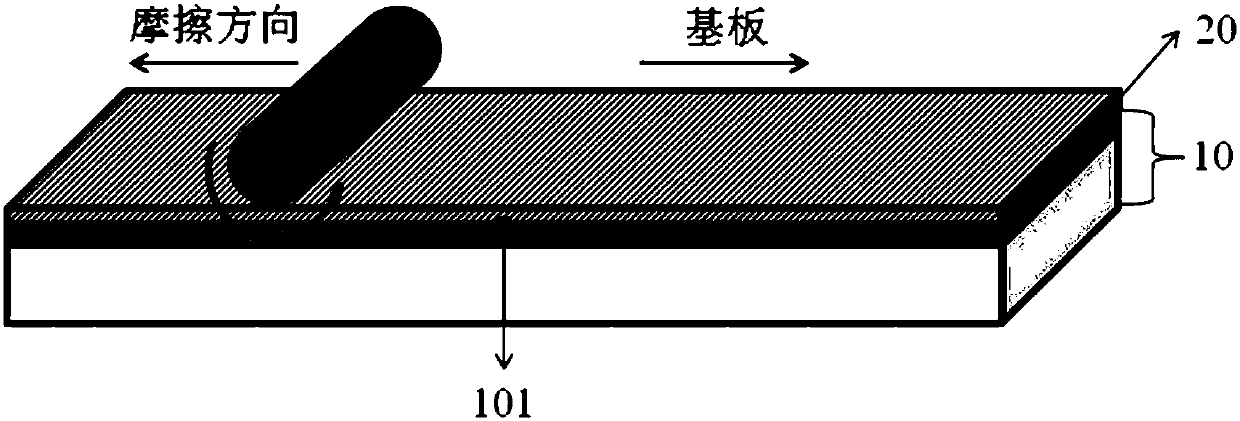

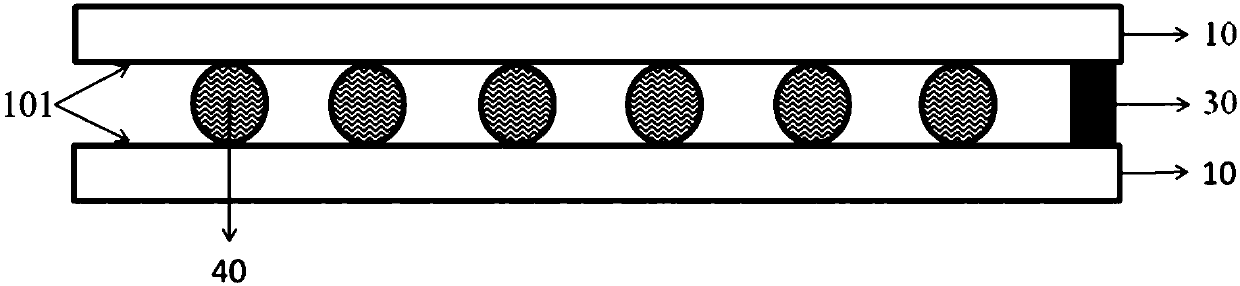

[0041] First, form an alignment layer on two ITO glass substrates respectively. The specific operation is as follows: first, use an alignment agent DL-2590 to configure a TN-type alignment agent solution with a suitable concentration, and apply the alignment agent solution evenly to the ITO glass by the spin coating method. On the substrate, solidify to form an alignment layer. Then, rubbing alignment was carried out along one direction on the ITO glass substrate provided with the alignment layer by using a roller with rubbing fleece. Next, spacers are sprayed on the rubbed monolithic ITO glass substrate, and the size of the spacers is 20 microns. Another piece of ITO glass substrate is fixed and pasted on the ITO glass substrate sprayed with spacers through UV curing glue to form a liquid crystal cell. The liquid crystal composition is configured according to formula 1, poured into a liquid crystal cell, and cured by ultraviolet light to seal the cell to obtain a bistable di...

Embodiment 2

[0043] First, form an alignment layer on two ITO glass substrates respectively. The specific operation is as follows: first, use an alignment agent DL-3260 to prepare an STN-type alignment agent solution with a suitable concentration, and apply the alignment agent solution evenly to the ITO glass by the spin coating method. On the substrate, solidify to form an alignment layer. Then, rubbing alignment was carried out along one direction on the ITO glass substrate provided with the alignment layer by using a roller with rubbing fleece. Next, spacers are sprayed on the rubbed monolithic ITO glass substrate, and the size of the spacers is 20 microns. Another piece of ITO glass substrate is fixed and pasted on the ITO glass substrate sprayed with spacers through UV curing glue to form a liquid crystal cell. The liquid crystal composition is configured according to formula 1, poured into a liquid crystal cell, and cured by ultraviolet light to seal the cell to obtain a bistable di...

Embodiment 3

[0045] First, form an alignment layer on two ITO glass substrates respectively. The specific operation is as follows: first, use the alignment agent DL-4018 to prepare a VA-type alignment agent solution with a suitable concentration, and apply the alignment agent solution evenly to the ITO glass by the spin coating method. On the substrate, solidify to form an alignment layer. Then, rubbing alignment was carried out along one direction on the ITO glass substrate provided with the alignment layer by using a roller with rubbing fleece. Next, spacers are sprayed on the rubbed monolithic ITO glass substrate, and the size of the spacers is 16 microns. Another piece of ITO glass substrate is fixed and pasted on the ITO glass substrate sprayed with spacers through UV curing glue to form a liquid crystal cell. The liquid crystal composition is configured according to formula 1, poured into a liquid crystal cell, and cured by ultraviolet light to seal the cell to obtain a bistable dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com