Mineral particle size screening mechanism

A screening and particle size technology, applied in the direction of screening, solid separation, grid, etc., can solve the problems that the screening results cannot be digitized, secondary pollution of the screening device, and low screening efficiency, etc., to achieve online control and automatic screening, noise reduction, and improved production environment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

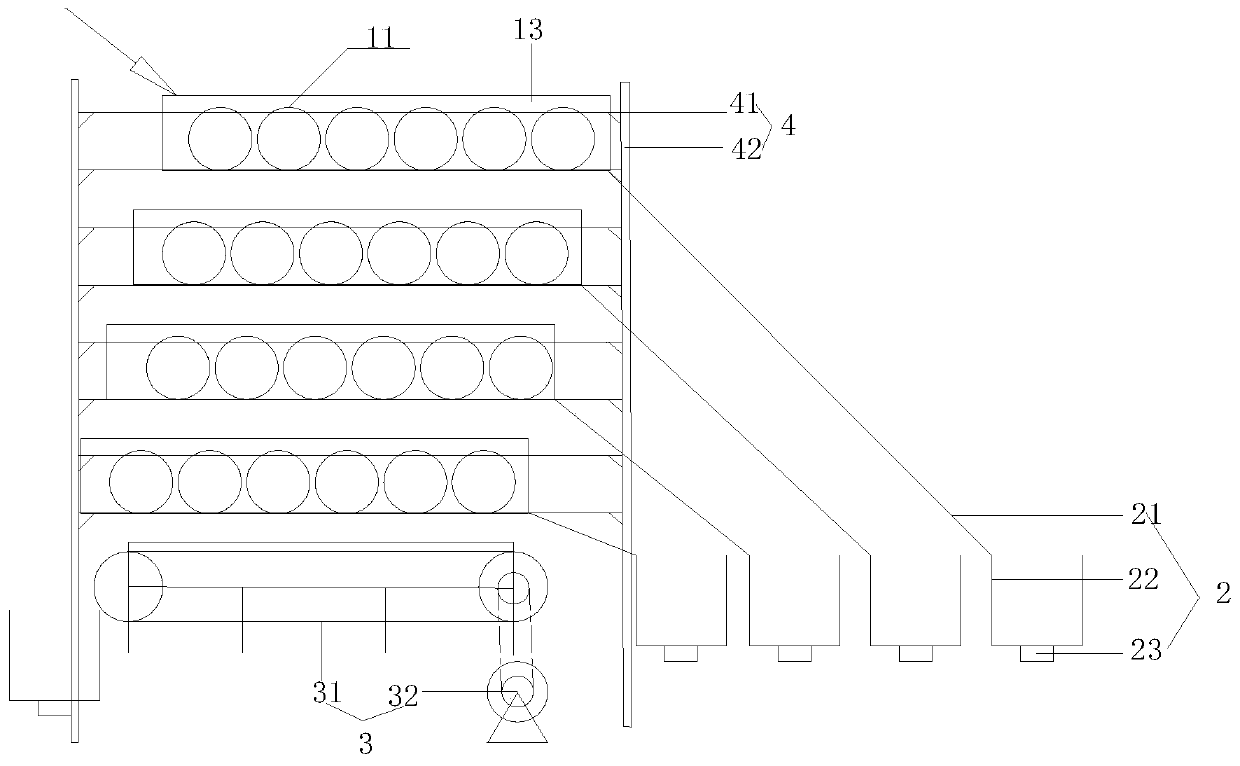

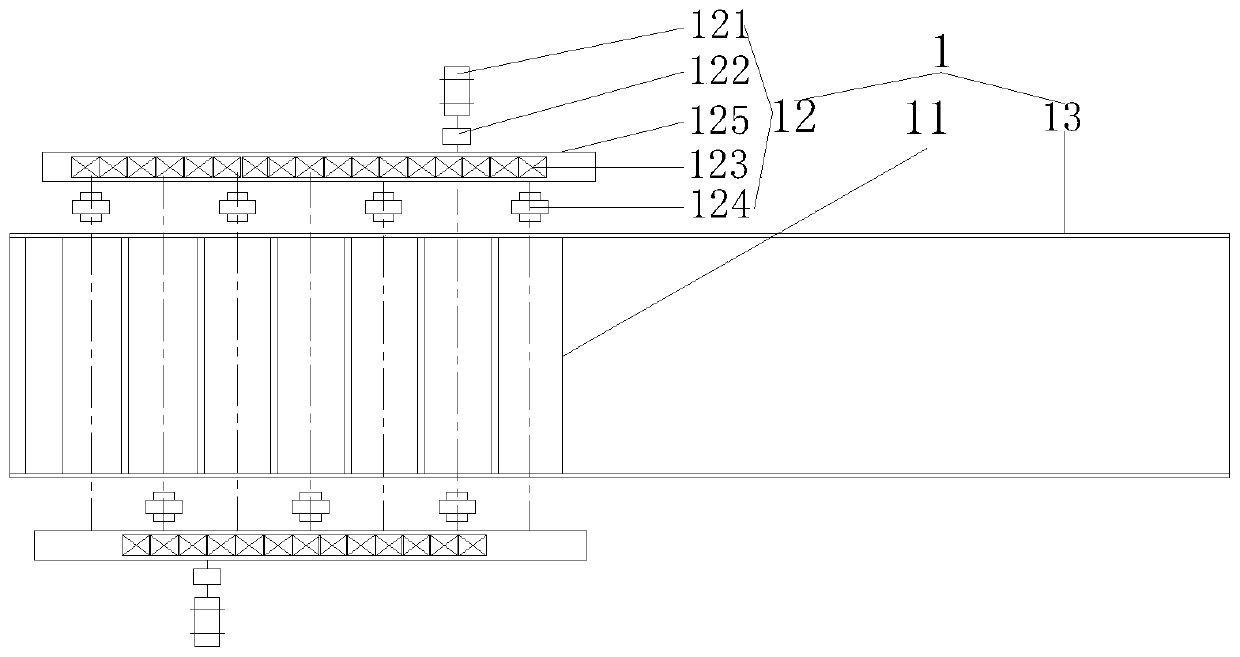

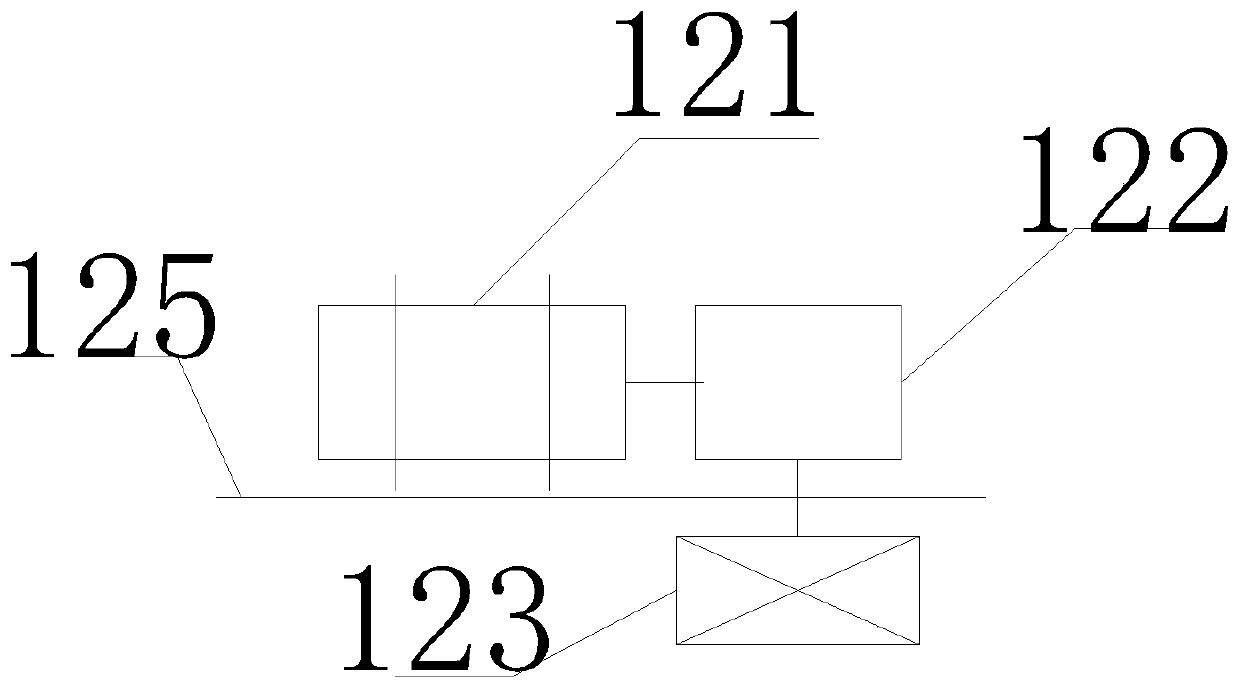

[0039] Such as figure 1 As shown, a mineral particle size screening mechanism includes from top to bottom: a number of screening devices 1, and the screening devices 1 are arranged at intervals, and each of the screening devices 1 is arranged horizontally and connected by a support frame Placed on the ground, if only one screening device 1 can be directly placed on the ground; each of the screening devices 1 includes a number of axles 11 and baffles 13, and each of the axles 11 is evenly spaced on the baffle 13 Above, the axles 11 rotate around their axes and in the same direction (uniformly turn to the right or left), and the distance between the axles 11 of the screening devices 1 gradually decreases from top to bottom. . Rotate in a unified direction like this so that the minerals screened out on each layer of wheel shafts can be collected from the same direction, and the gap between each of the wheel shafts 11 of the screening device 1 at all levels from top to bottom gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com