Forming method of net size RTM of metal rudder core and resin matrix composite material

A technology of composite materials and molding methods, which can be applied to other household appliances, household appliances, household components, etc., can solve the problems of incomplete fiber structure, poor ablation resistance, discontinuous fibers, etc., achieve low production cost, improve burning Corrosion performance, the effect of solving fiber discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

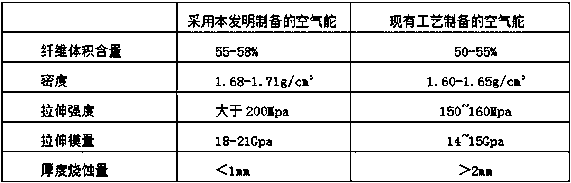

Embodiment 1

[0028] Cut the quartz woven fabric according to the expansion diagram of the front edge extension of the air rudder; the quartz woven fabric is a three-dimensional weaving structure, and the thickness of a single layer is (0.1~2.5) mm. Then the cut fabrics are stacked and flattened, and the laminated fabrics are no less than 4 layers, and then sewn into a whole by the normal through-sewing method, so that the front edge glass fiber reinforced plastic strip prefabricated part is obtained; the front edge glass reinforced plastic strip prefabricated part is put into In the fiberglass rod mold, close the mold, use an oven to preheat and dehumidify the mold and prefabricated parts, the preheating temperature is 70°C, the preheating time is 5h, and at the same time vacuum the mold cavity, the vacuum degree is -0.9MPa; weigh 2.0kg of phenolic resin, preheated at 70°C for 30 minutes, and then use the RTM glue injection machine to pour the resin into the mold cavity under the glue injec...

Embodiment 2

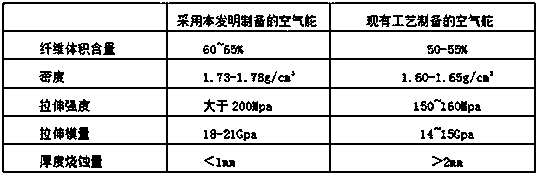

[0036] Cut the quartz woven fabric according to the expansion diagram of the front edge extension of the air rudder; the quartz woven fabric is a three-dimensional weaving structure, and the thickness of a single layer is 0.1~2.5mm. Then the cut fabrics are stacked and flattened, and the laminated fabrics are no less than 4 layers, and then sewn into a whole by the normal through-sewing method, so that the front edge glass fiber reinforced plastic strip prefabricated part is obtained; the front edge glass reinforced plastic strip prefabricated part is put into In the fiberglass rod mold, close the mold, use an oven to preheat and dehumidify the mold and prefabricated parts, the preheating temperature is 60°C, the preheating time is 5h, and at the same time vacuum the mold cavity, the vacuum degree is -0.8MPa; weigh 1.5kg of phenolic resin, preheated at 60°C for 20°C, so that the injected resin can soak into the fabric (front-edge FRP strip prefabrication), and then heat up and ...

Embodiment 3

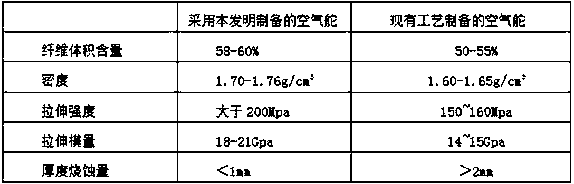

[0045] Cut the quartz woven fabric according to the expansion diagram of the front edge extension of the air rudder; the quartz woven fabric is a three-dimensional weaving structure, and the thickness of a single layer is 0.1~2.5mm. Then the cut fabrics are stacked and flattened, and the laminated fabrics are no less than 4 layers, and then sewn into a whole by the normal through-sewing method, so that the front edge glass fiber reinforced plastic strip prefabricated part is obtained; the front edge glass reinforced plastic strip prefabricated part is put into In the FRP strip mould, close the mold and use an oven to preheat and dehumidify the mold and prefabricated parts. The preheating temperature is 60~70°C and the preheating time is 5h. At the same time, the mold cavity is evacuated to a vacuum degree of -0.85MPa; Weigh 1.8kg of phenolic resin, preheat it at 65°C for 25 minutes, and then use the RTM glue injection machine to pour the resin into the mold cavity under the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com