Heatable cloth guide roller

A fabric guide roller and heating tube technology, which is used in heating/cooling fabrics, textile processing machine accessories, fabric finishing guides/expanders, etc., can solve the problems of uneven heating of fabrics, decreased output quality, and high energy consumption. , to achieve the effect of short transfer path, small loss and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

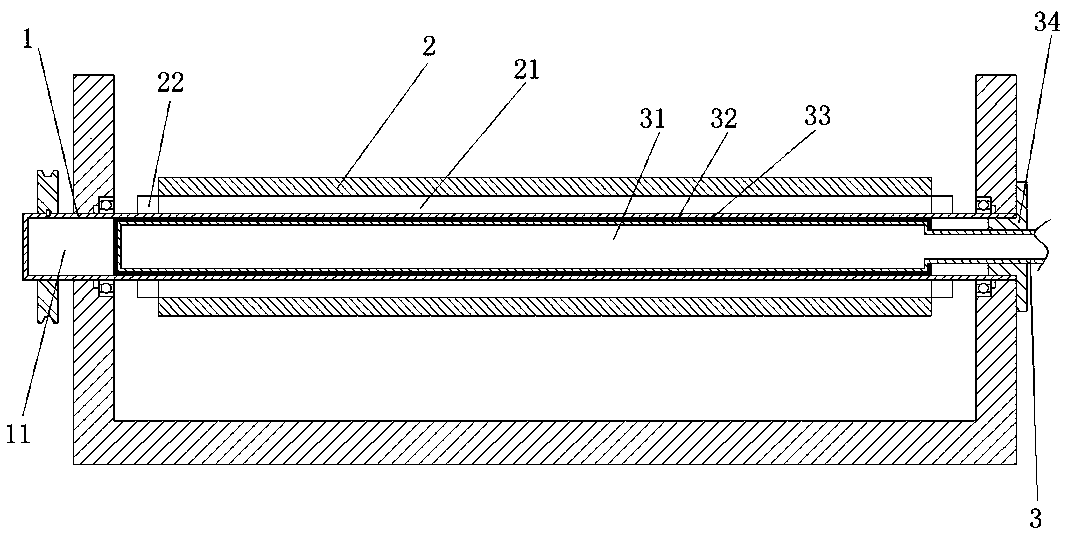

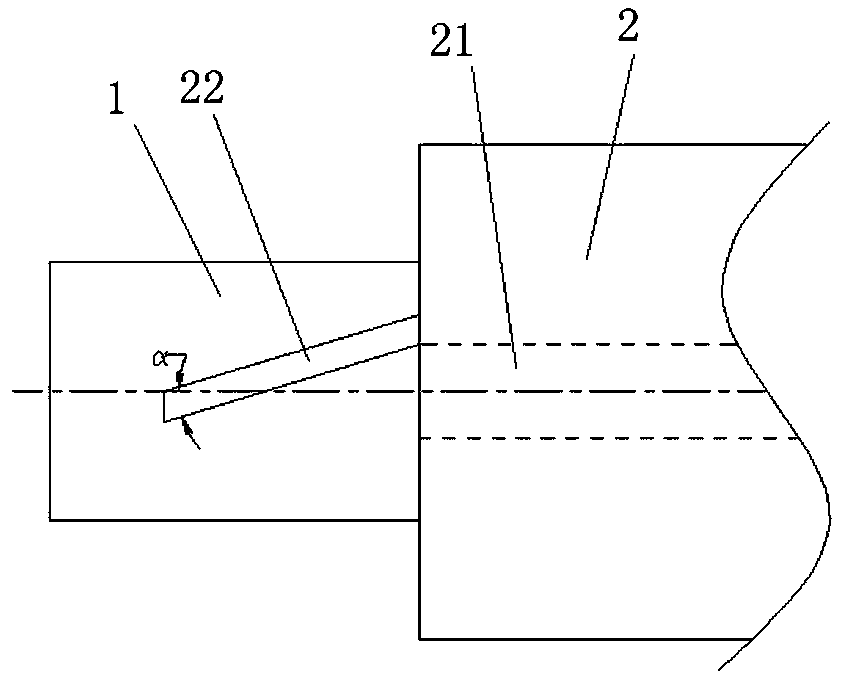

[0025] Such as figure 1 , 2 . A heating cloth guide roller shown in 3, including a longer roller shaft 1 and a shorter roller 2 coaxial inside and outside, which are integrally formed by machining, the cloth guide roller in this embodiment is used for setting in printing and dyeing The cloth is driven in the tank to move and dye in the dye. The two ends of the roller shaft 1 are rotatably installed between the two side walls of the printing and dyeing tank through bearings. The inner part of the roller shaft 1 is machined with a cavity 11 coaxial with it. Through the end of the roller shaft 1, a heating device 3 is installed in the cavity 11 from the outside to the inside of the printing and dyeing tank. Both ends of the roller shaft 1 pass through the side wall of the printing and dyeing tank. It is used to connect a chain or belt and finally connect to an external drive motor so that it can rotate under the drive of the drive motor and transmit the rotation to the fabric, a...

Embodiment 2

[0035] The technical solution described in Embodiment 2 is similar to Embodiment 1, the difference is that

[0036] Such as Figure 4 As shown, the cloth guide roller in this embodiment is applied in a drying box for drying shaped cloth, and its overall installation structure is similar to that in Embodiment 1, and it also includes an end cover 4, which is a plastic middle wearer. The shape of the rotating body passing through the roller shaft 1, which can be detachably located at both ends of the roller 2 by clamping or screwing and covering the opening of the flow groove 21, thereby reducing heat loss from the flow groove 21 and ensuring more heat concentration The drying and shaping of the cloth is realized on the surface of the roller 2.

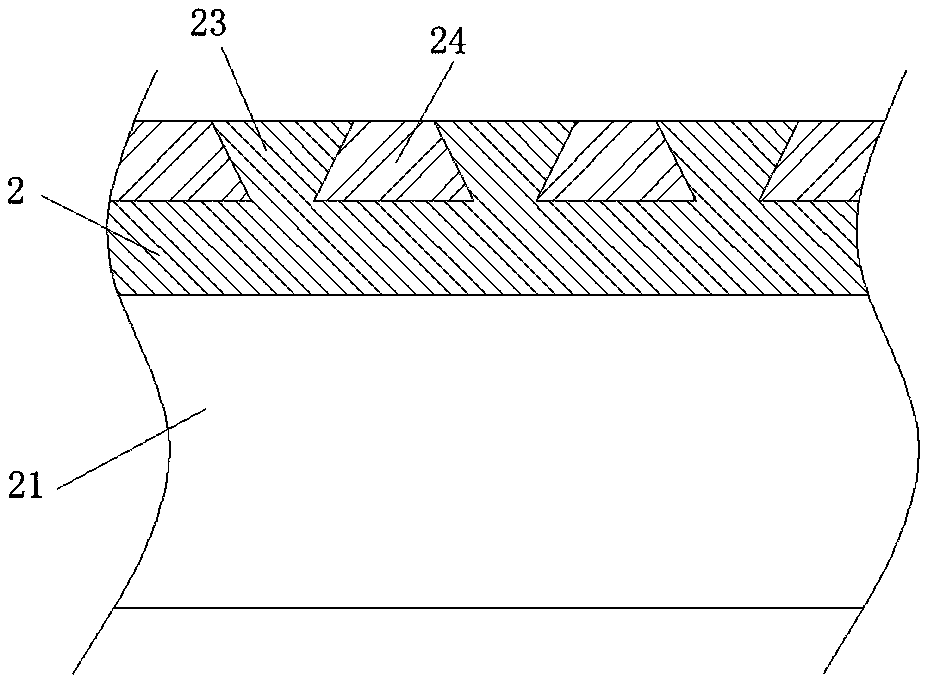

[0037] In this embodiment, the surface of the heating tube 31 protrudes a plurality of bosses along its axial direction to form a segmented heating surface 32 that contacts the inner wall of the roller shaft 1 for heat transfer, thereby...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com