Vacuum and pressure test bench for full pipeline of braking system

A braking system and pressure testing technology, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, fluid tightness test, machine/structural component testing, etc. , Unable to provide data support for filling process verification, unable to reflect the real vacuum and pressure status, etc., to facilitate real-time monitoring data, save parameter correction time, and avoid repeated testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

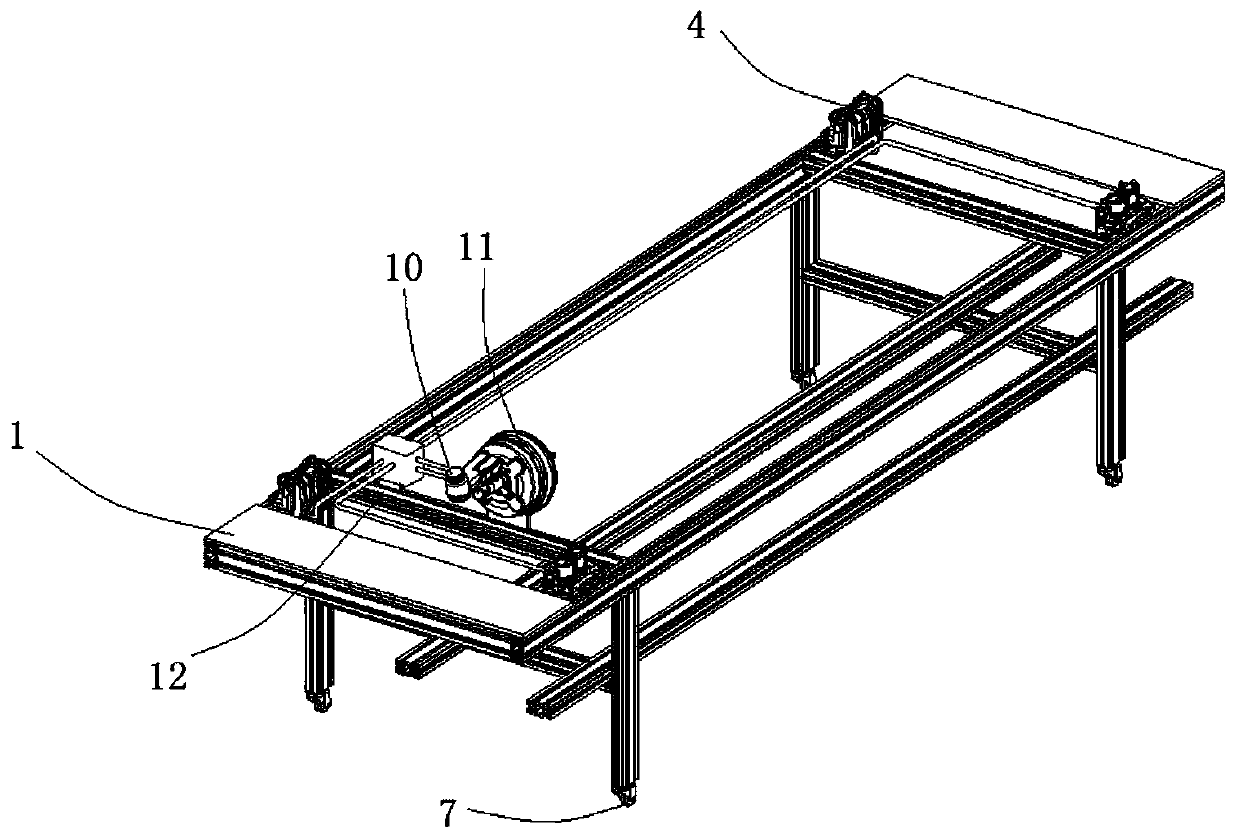

[0029] see figure 1 As shown, the embodiment of the present invention provides a vacuum and pressure test bench for the entire pipeline of the brake system, including a frame body 1, a collection device and a transmission device, and the frame body 1 is provided with a brake fluid pot 10, a booster Device 11 and pipeline system, the pipeline system is set on the frame body 1, the brake fluid pot 10 communicates with the pipeline system through the booster device 11, and the filling fluid filling equipment fills the filling fluid through the brake fluid pot 10 To the pipeline system; the collection device is set on the pipeline system, which is mainly used to collect the vacuum degree and pressure value of at least two points in the pipeline system, wherein one of the two points is located in the pipeline system far away from the booster device 11 One end of the pipeline system is the end of the pipeline system, and the other point is located on other connecting sections of the...

Embodiment 2

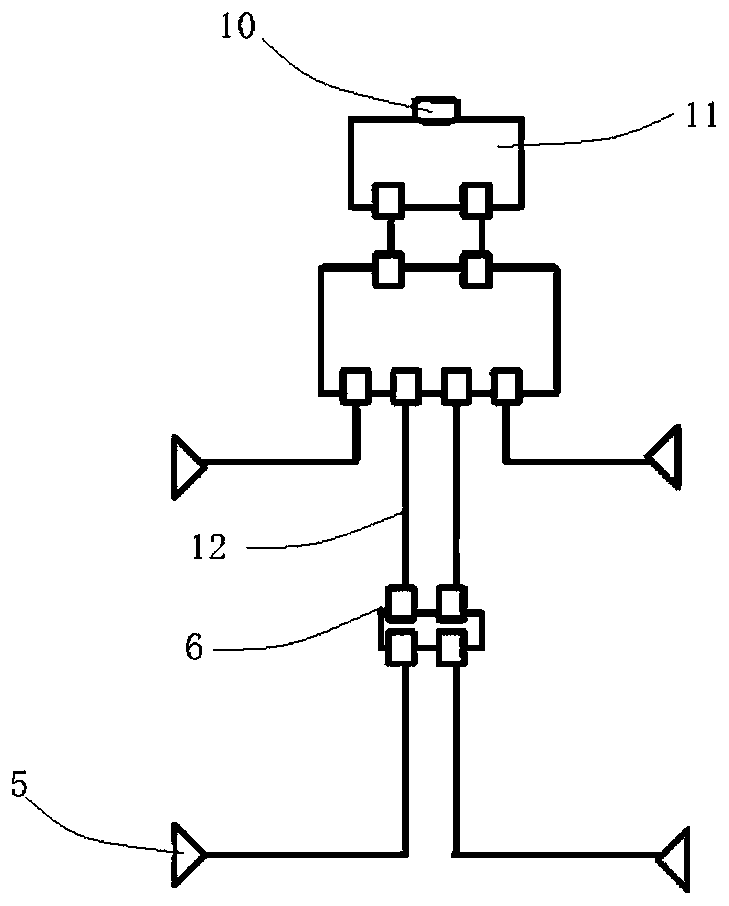

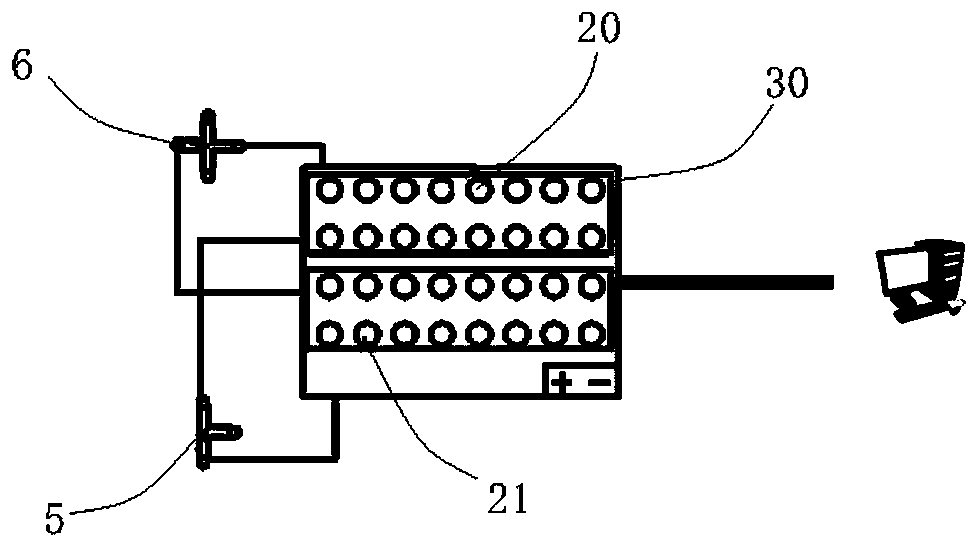

[0036] Basic content is the same as embodiment 1, and the difference with embodiment 1 is, see Figure 2-3 As shown, the piping system also includes a plurality of three-way valves 5 and four-way valves 6. The three-way valves 5 are used to communicate the pipeline 12 with the exhaust port and the vacuum sensor 20 and pressure sensor 21 located at the exhaust port. The valve 6 is used to connect the connections between the various pipelines 12 , and for the sake of equipment and cost saving, other vacuum sensors 20 and pressure sensors 21 except those arranged at the ends are respectively provided at the connection of every two adjacent pipelines 12 . Specifically, two ends of each four-way valve 6 are respectively connected to its adjacent pipeline 12, and the remaining two ends are respectively connected to a vacuum sensor 20 and a pressure sensor 21, and one end of each three-way valve 5 is connected to an exhaust The remaining two ends are connected to the vacuum sensor 20...

Embodiment 3

[0038] The basic content is the same as that of Embodiment 2, and the difference from Embodiment 2 is that the transmission device includes a data acquisition card 30, and the data acquisition card 30 is connected to the vacuum sensor 20 and the pressure sensor 21, and the data acquisition card 30 is used to transmit the vacuum collected. Degree and pressure value, and the collected vacuum degree and pressure value are transmitted to the computer which can be displayed and analyzed and processed, which is convenient for the operator to monitor the monitored data in real time, and is convenient for observation and analysis and processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com