Energy-saving scheduling control method taking equipment maintenance into consideration for hybrid flow shop

A technology for equipment maintenance and scheduling control, applied in the general control system, program control, comprehensive factory control, etc., can solve problems such as safety hazards, energy consumption, production delays, etc., to prevent loss, expand sampling space, improve computing speed and The effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

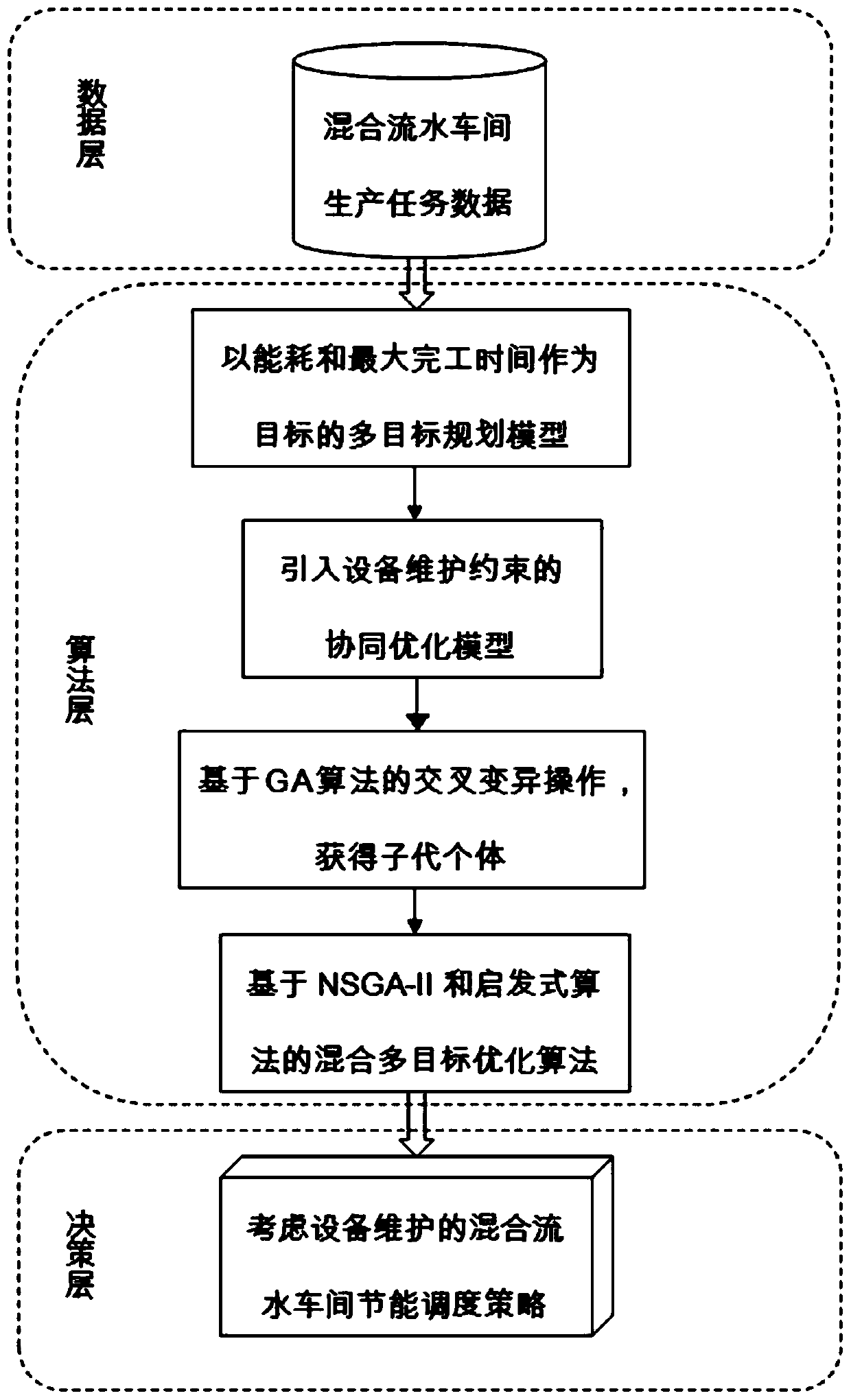

[0060] like figure 1 Shown is a flow chart of an energy-saving scheduling control method for a mixed flow workshop considering equipment maintenance according to the present invention. The method specifically includes the following steps:

[0061] Step 1: Obtain the production constraints and solve the objective function according to the production characteristics of the mixed flow workshop, and introduce the energy consumption target to establish a multi-objective programming model;

[0062] Step 2: Analyze the impact of equipment maintenance on production scheduling based on equipment maintenance data, and add equipment maintenance as corresponding constraints to the multi-objective programming model to form a complete multi-objective programming model;

[0063] Step 3: Use the GA (genetic) algorithm to perform coding genetic operations on the actual mixed flow workshop to obtain offspring individuals;

[0064] Step 4: Use NSGA-II (non-dominated sorting genetics with elitis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com