Autoclave Forming Method for Composite Material Intake Lip

A technology of autoclave molding and composite materials, which is applied in the field of autoclave molding of composite material inlet lip, can solve the problems of high porosity, poor and poor resin, and uneven surface, so as to improve thermal conductivity and reduce The effect of internal temperature difference and increasing constant temperature time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

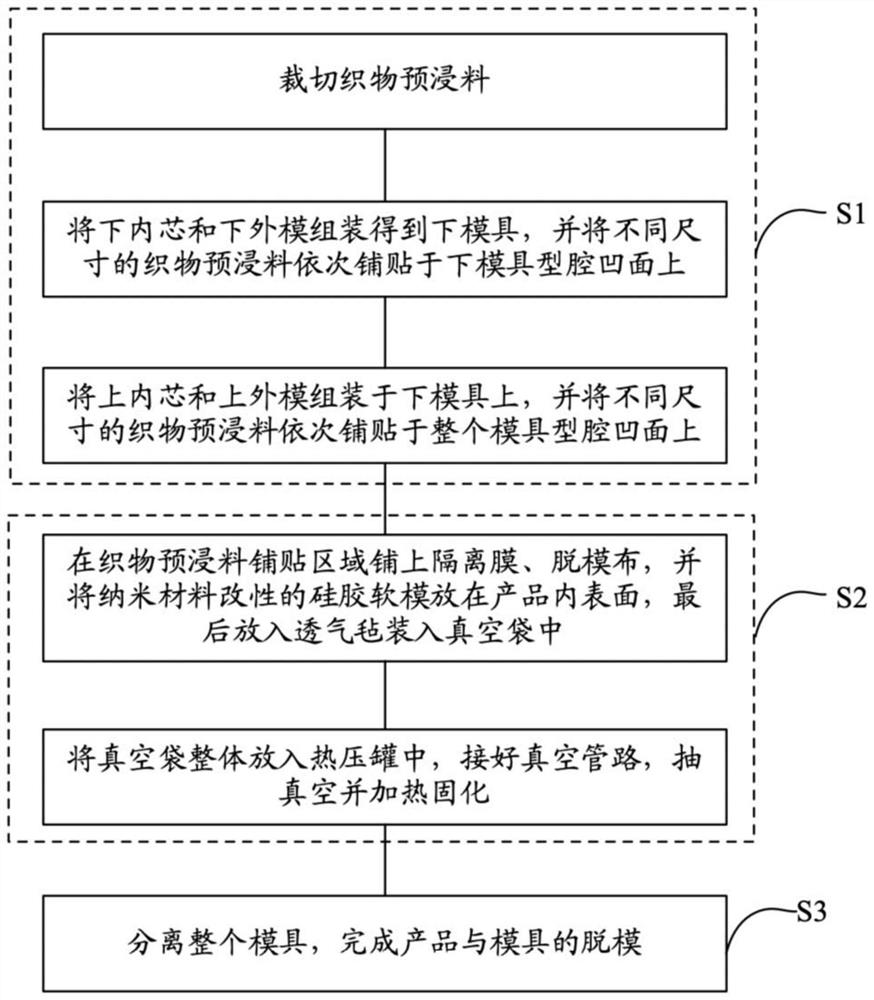

[0079] (1) Composite material layup:

[0080] 1) Mold preparation: use soft materials to wipe the mold cavity clean, and use liquid release agent to treat the surface of the mold for 6 times, with an interval of 10 minutes between each time;

[0081] 2) Cutting: Use an automatic cloth cutting machine to cut the glass fiber twill fabric prepreg with a protective film according to the size and shape required by the drawing, and pay attention to the type and fiber direction of the glass fiber twill fabric prepreg when cutting. Glass fiber twill fabric prepreg, the specification is 180g / m 2 , resin content 34%;

[0082] 3) Paving

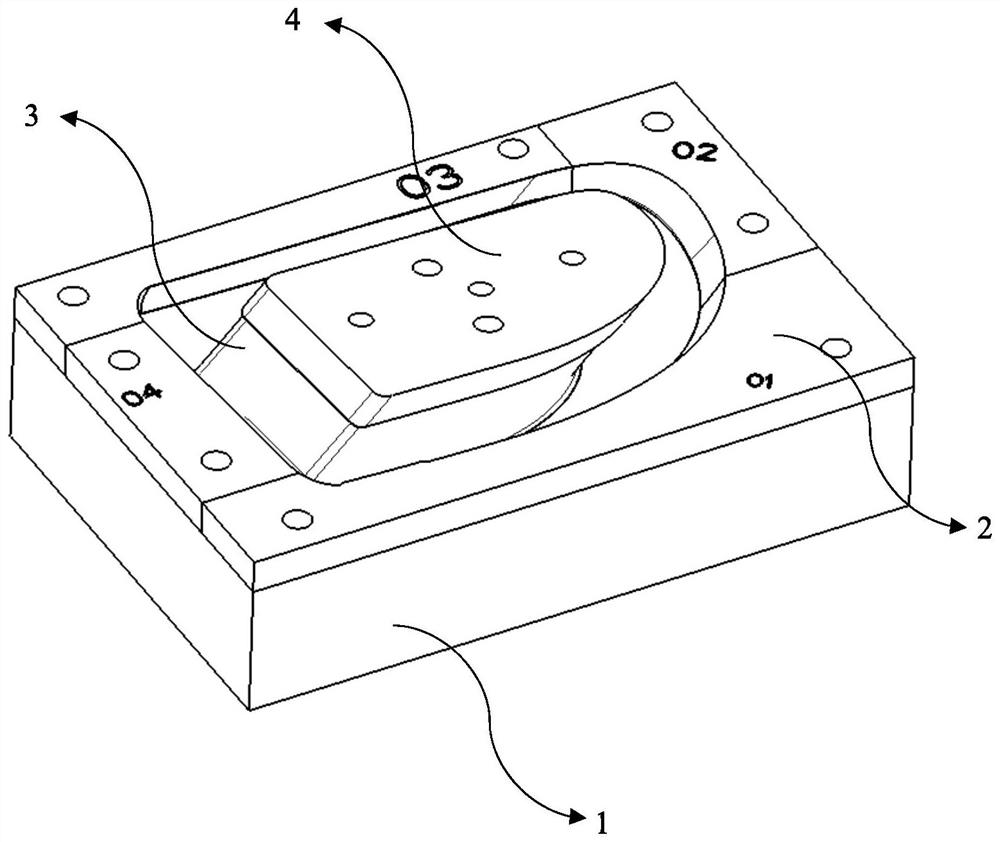

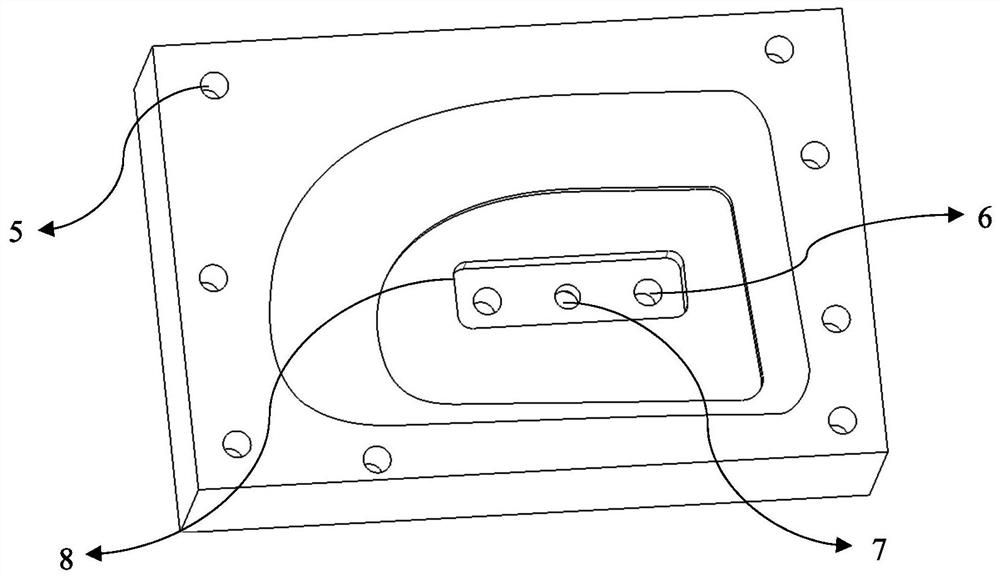

[0083] ① Lower mold assembly: place the positioning boss 9 on the lower inner core 3 in the positioning groove 8 on the lower outer mold 1, and the bolts pass through the bolt holes 7 to fix the lower outer mold 1 and the lower inner core 3 together;

[0084] ② Lay glass fiber twill fabric prepregs of different sizes on the concave surface of the low...

Embodiment 2

[0100] (1) Composite material layup:

[0101] 1) Mold preparation: use soft materials to wipe the mold cavity clean, and use a liquid release agent to treat the surface of the mold for 5 times, with an interval of 15 minutes between each time;

[0102] 2) Cutting: Use an automatic cloth cutting machine to cut the carbon fiber plain weave fabric prepreg with a protective film according to the size and shape required by the drawing, and pay attention to the model and fiber direction of the carbon fiber plain weave fabric prepreg when cutting. Carbon fiber plain weave fabric prepreg, the specification is 200g / m 2 , the resin content is 40%;

[0103] 3) Paving

[0104] ① Lower mold assembly: place the positioning boss 9 on the lower inner core 3 in the positioning groove 8 on the lower outer mold 1, and the bolts pass through the bolt holes 7 to fix the lower outer mold 1 and the lower inner core 3 together;

[0105] ② Lay carbon fiber plain weave fabric prepregs of different s...

Embodiment 3

[0121] (1) Composite material layup:

[0122] 1) Mold preparation: use soft materials to wipe the mold cavity clean, and use liquid release agent to treat the surface of the mold for 4 times, with an interval of 30 minutes between each time;

[0123] 2) Cutting: Use an automatic cloth cutting machine to cut glass fiber twill fabric prepreg and carbon fiber plain weave fabric prepreg with protective film according to the size and shape required by the drawing, pay attention to the types of the two prepregs when cutting and fiber direction. Carbon fiber plain weave fabric prepreg, the specification is 200g / m 2 , resin content 40%, glass fiber twill fabric prepreg, specification 180g / m 2 , resin content 34%;

[0124] 3) Paving

[0125] ① Lower mold assembly: place the positioning boss 9 on the lower inner core 3 in the positioning groove 8 on the lower outer mold 1, and the bolts pass through the bolt holes 7 to fix the lower outer mold 1 and the lower inner core 3 together; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com