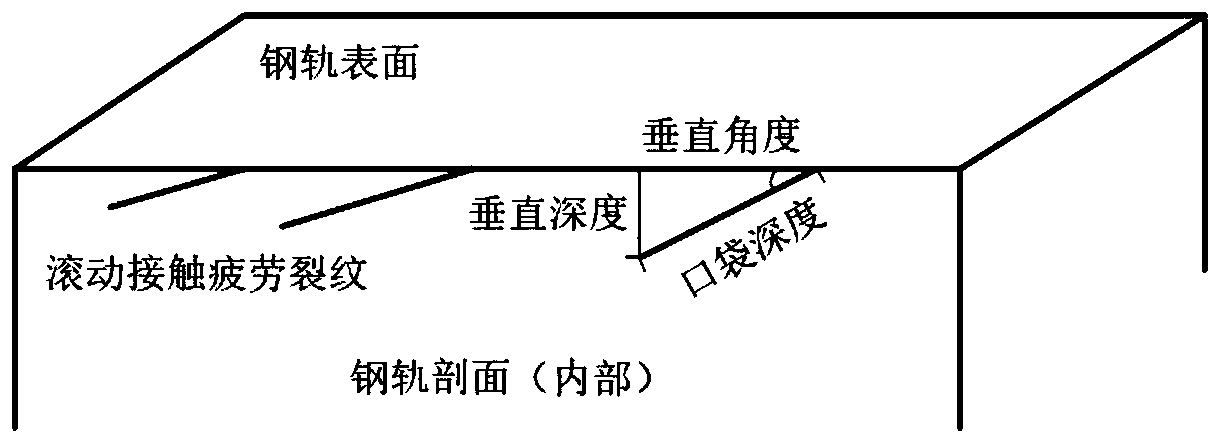

Method for nondestructively detecting extended vertical depth of roll contact fatigue of steel rail

A technology of rolling contact fatigue and vertical depth, applied in the direction of electric/magnetic depth measurement, magnitude/direction of magnetic field, electromagnetic measuring device, etc., to achieve the effect of simple operation, good safety and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

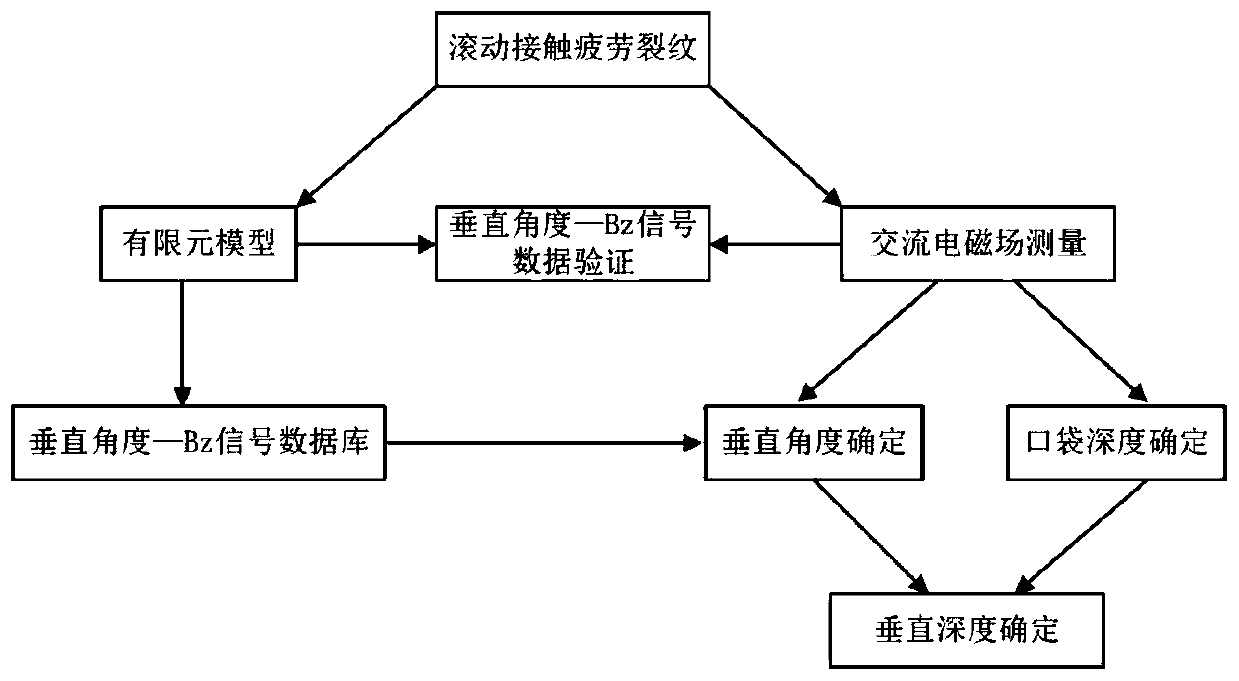

Method used

Image

Examples

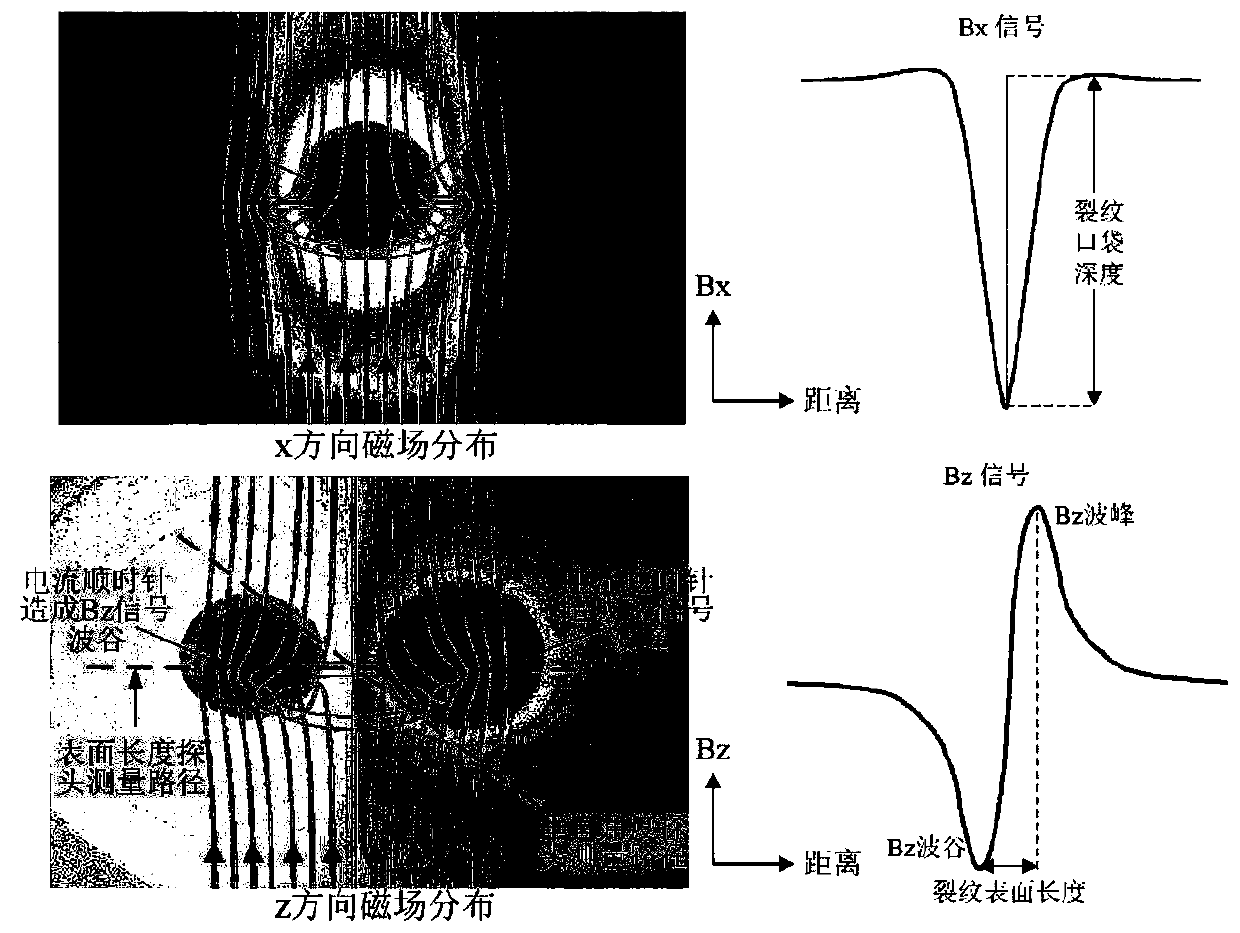

Embodiment 1

[0019] Under laboratory conditions, single cracks with different vertical depths are made on the rail by EDM, and AC electromagnetic field measurements are performed on the cracks according to steps 1 and 2 to obtain Bx and Bz signals, and the crack pocket depth, surface length and Bz are calculated The trough-to-peak ratio. Input the crack pocket depth, surface length and Bz trough-to-peak ratio in the finite element database established in steps 3 and 4 to obtain the vertical angle of the crack, and use trigonometric functions to calculate the vertical crack depth. The comparison between the finite element simulation and the actual measured Bz trough-to-peak ratio is shown in the appendix Figure 4 .

Embodiment 2

[0021] The difference between this application example and Example 1 is that the detection object is the rolling contact fatigue crack cluster in the actual rail (generally composed of multiple cracks with a distance of about 1-20 mm). Similarly, the finite element model is used to establish the crack cluster information database, and the longest vertical depth of cracks in the crack cluster is measured and judged, so as to completely remove the cracks. The AC electromagnetic field measuring probe scans the center point of the crack in a direction of 45° to the crack surface length to obtain the Bz trough-to-peak ratio, and input the data into the database to calculate the vertical angle of the crack. Combined with the pocket depth, the maximum vertical depth of the crack is calculated. The calculation results are compared with the actual results as shown in the table below:

[0022] Table 1 applies the method of the present invention to calculate the vertical depth of the cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com