Piezoelectric vibration energy collection system capable of tracing maximum power point

A technology of maximum power point and piezoelectric vibration, applied in the direction of output power conversion device, piezoelectric effect/electrostrictive or magnetostrictive motor, adjusting electric variable, etc., can solve the problem that the maximum output power of energy extraction circuit is limited Issues such as output power, load dependence, and low efficiency of piezoelectric vibration energy harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

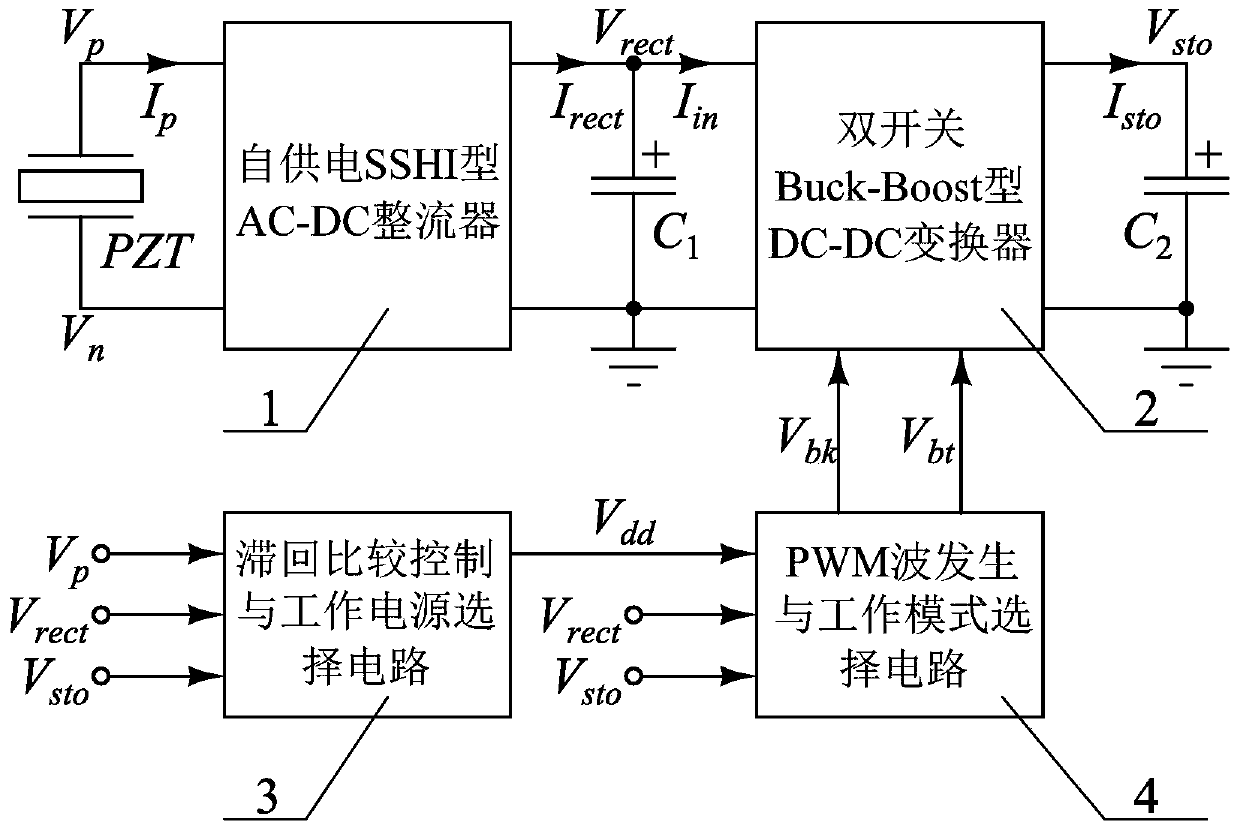

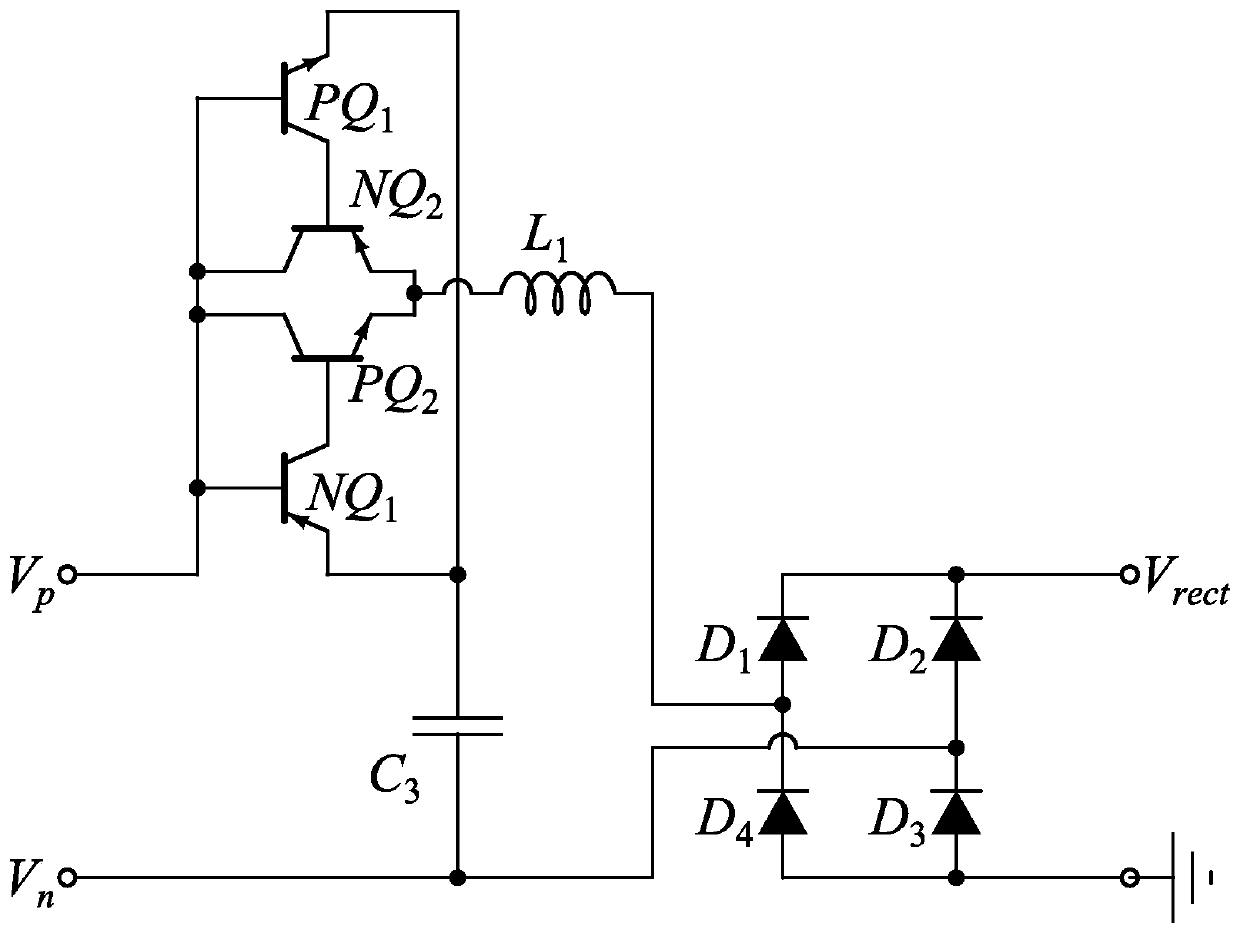

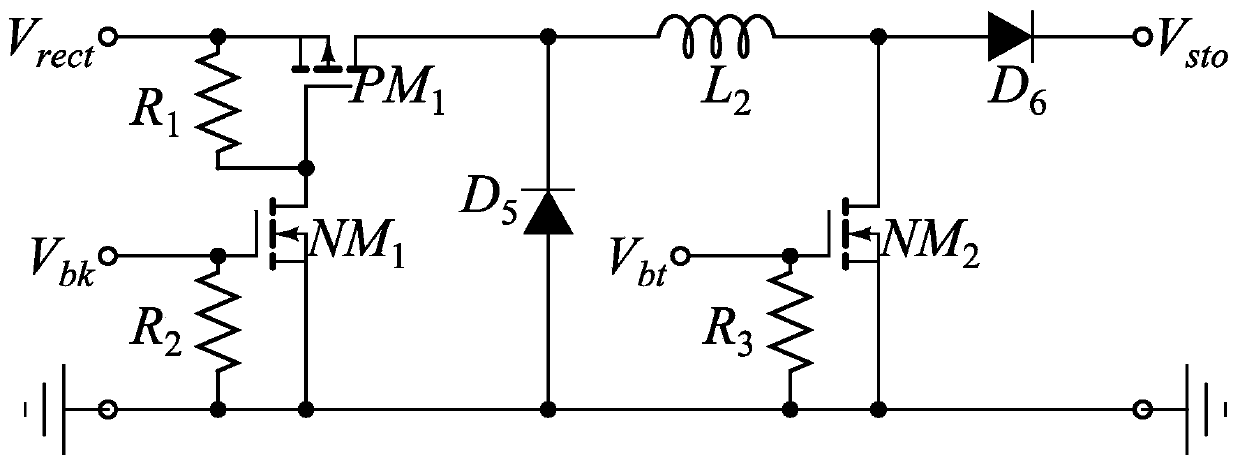

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Embodiment one: if figure 1 As shown, a piezoelectric vibration energy harvesting system capable of tracking the maximum power point, including a piezoelectric transducer PZT and an electric energy extraction circuit, the piezoelectric transducer PZT is used to capture vibration energy and convert the vibration energy into AC output, The power extraction circuit includes self-powered SSHI AC-DC rectifier 1, double-switch Buck-Boost DC-DC converter 2, hysteresis comparison control and working power selection circuit 3, PWM wave generation and working mode selection circuit 4, the first The capacitor C1 and the second capacitor C2, the first capacitor C1 and the second capacitor C2 are both electrolytic capacitors, and the double-switch Buck-Boost type DC-DC converter 2 has two working modes: Buck step-down operation mode and Boost step-up operati...

Embodiment 2

[0020] Embodiment two: this embodiment is basically the same as embodiment one, the difference is as follows:

[0021] Such as figure 1 As shown, in this embodiment, the piezoelectric transducer PZT has a first output terminal and a second output terminal, and the self-powered SSHI type AC-DC rectifier 1 has a first input terminal, a second input terminal, an output terminal and a ground terminal , the double-switch Buck-Boost DC-DC converter 2 has an input terminal, a first control terminal, a second control terminal, an output terminal and a ground terminal, and the hysteresis comparison control and working power supply selection circuit 3 has a first input terminal, a second control terminal, and a ground terminal. Two input terminals, a third input terminal and an output terminal, the PWM wave generation and operation mode selection circuit 4 has a power supply terminal, a first input terminal, a second input terminal, a first output terminal and a second output terminal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com