Spray irrigation robot system with function of precise watering

A robot system and robot technology, applied in watering devices, general control systems, control/regulation systems, etc., can solve problems such as high repeatability, low efficiency, and unfavorable growth of moss and other plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

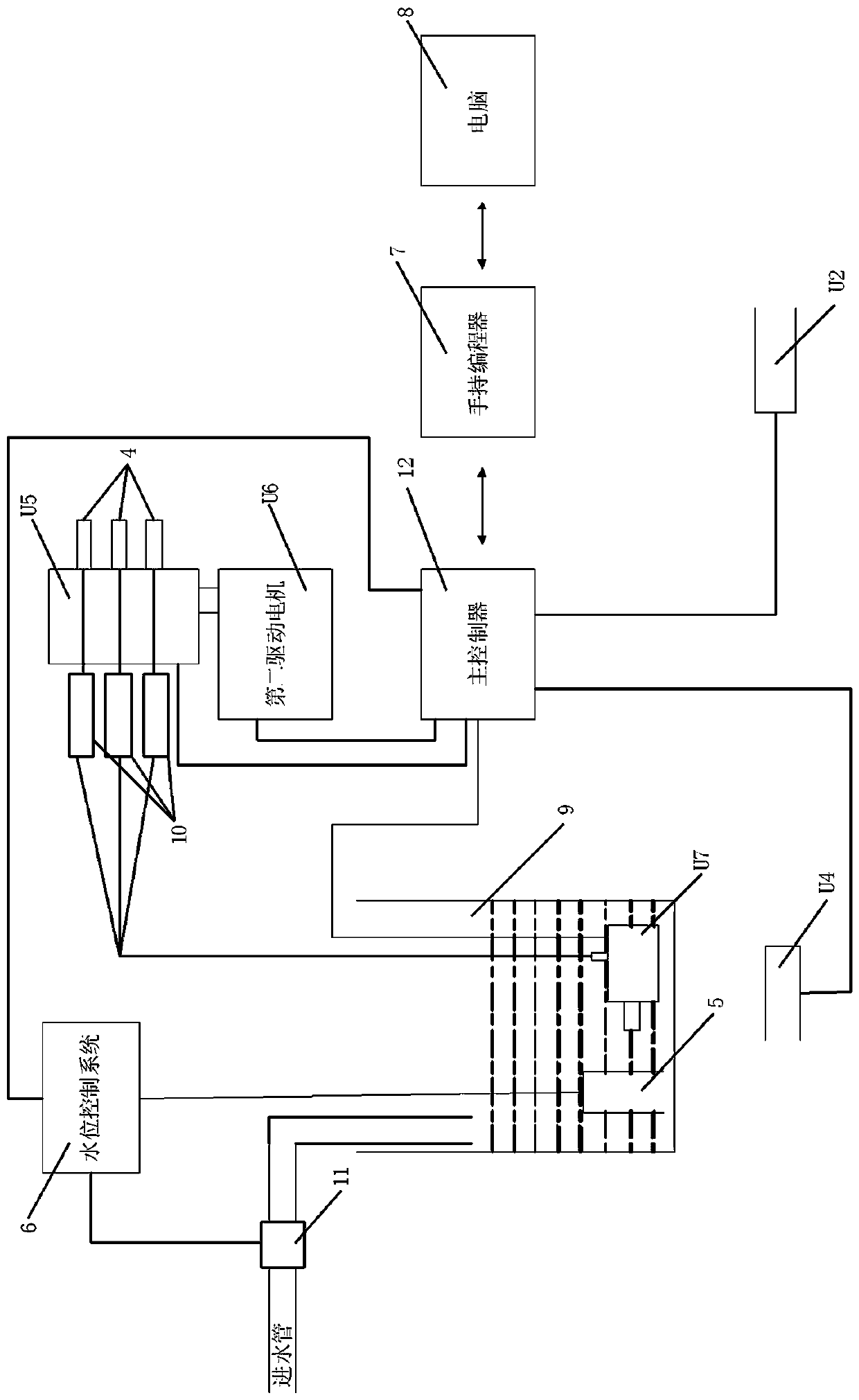

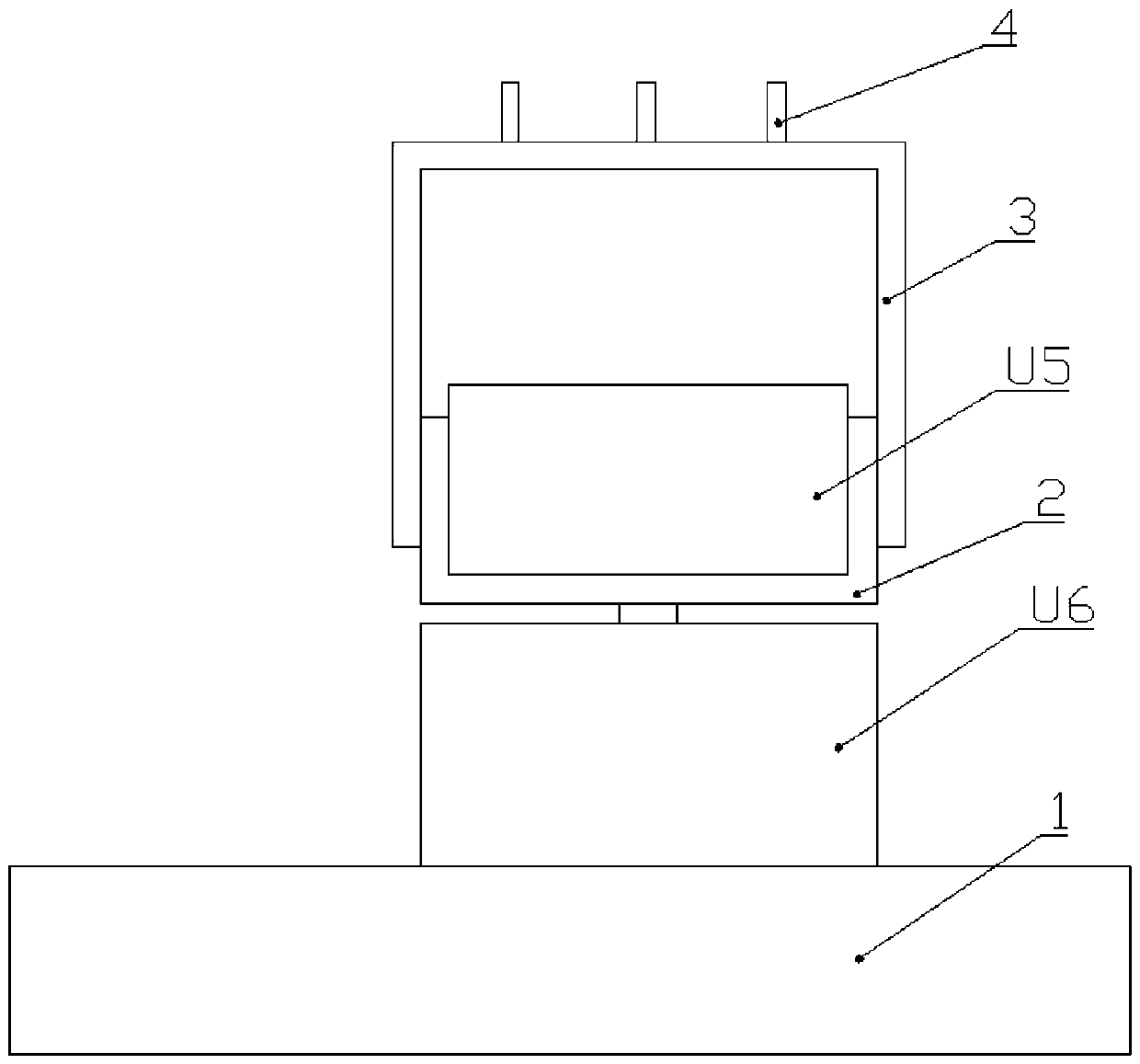

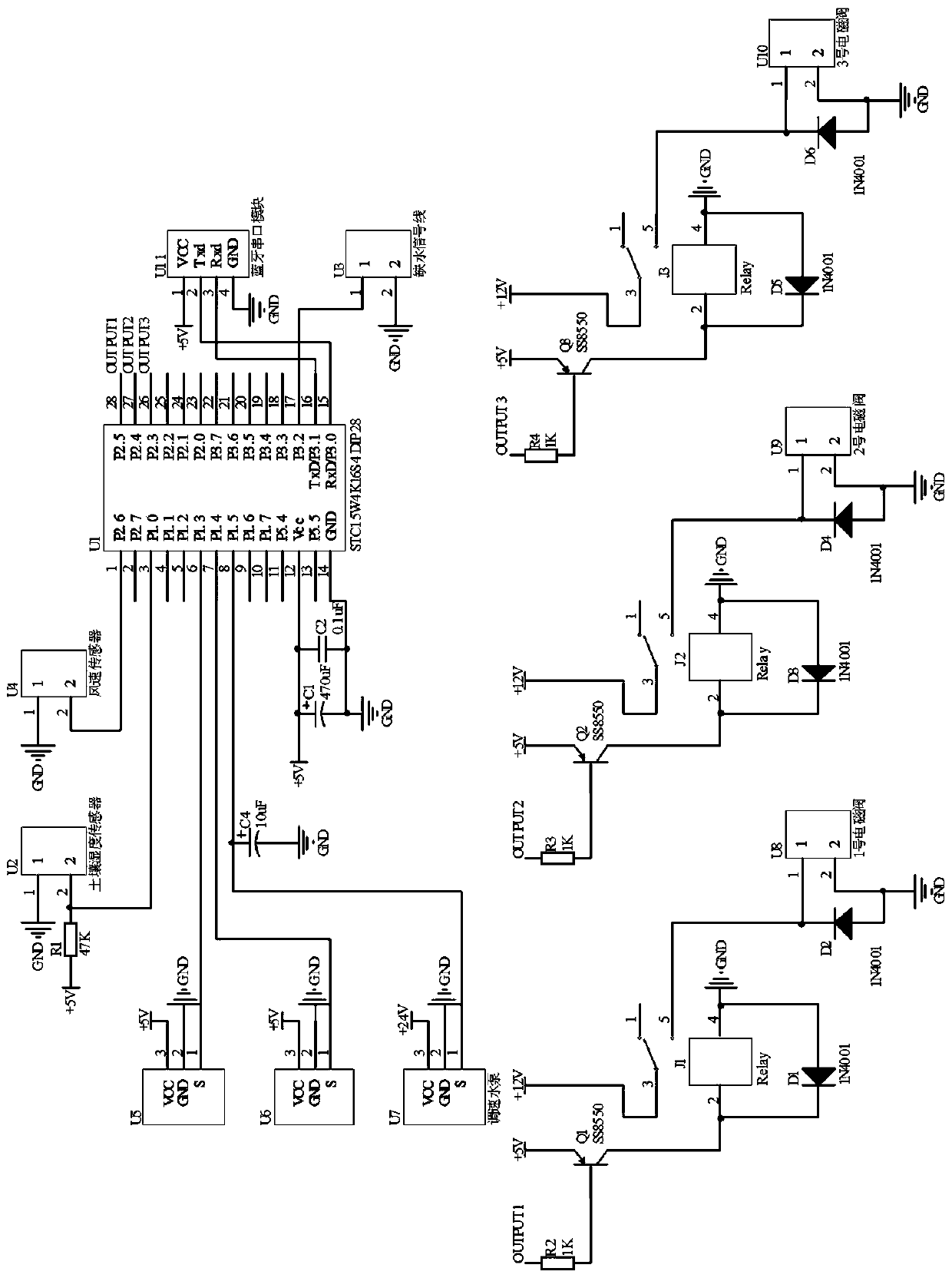

[0029] see Figure 1 to Figure 6, an embodiment of a sprinkler robot system capable of precise watering, including a robot main body, a speed-regulating water pump U7, a handheld programmer 7, a soil moisture sensor U2, and a wind speed sensor U4. controller 12. The two-degree-of-freedom platform includes a horizontal rotation assembly 2 that can rotate 180° left and right, a vertical rotation assembly 3 that can rotate 180° up and down, the second drive motor U6 of the horizontal rotation assembly is installed on the base 1, and the vertical rotation assembly 3 The first drive motor U5 is installed on the horizontal rotation assembly 2, and the horizontal rotation assembly 2 and the second drive motor U6 are circumferentially fixed, the first drive motor U5 is fixed on the horizontal rotation assembly 2, and the vertical rotation assembly 3 It is circumferentially fixed with the first driving motor U5. The second drive motor U6 drives the horizontal rotation assembly 2 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com