Novel glass fiber reinforced plastic grating automatic fiber sliding machine

A technology of wire sliding machine and glass fiber reinforced plastic, which is applied in metal processing and other directions, can solve the problems of high labor cost, low efficiency of glass fiber reinforced plastic grille, and long time, and achieve the effect of improving production efficiency, reducing occupational diseases and reducing harmfulness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

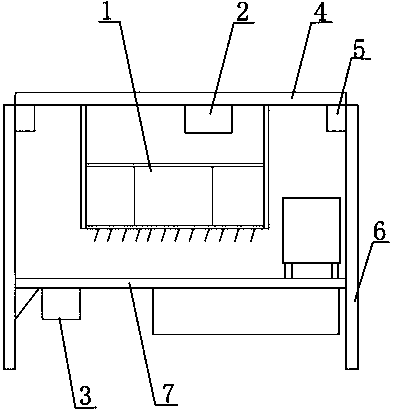

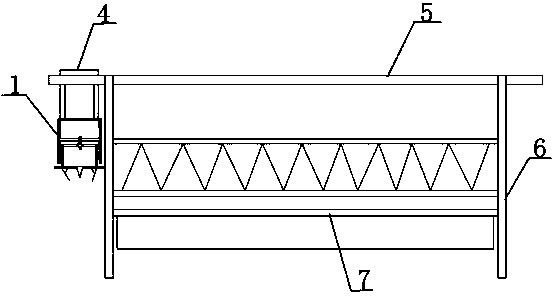

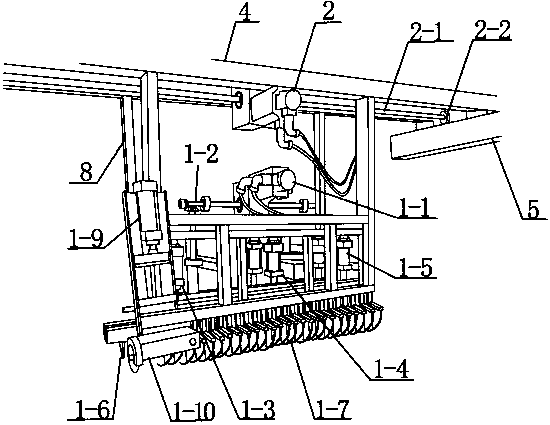

[0012] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the accompanying drawings, the present invention

[0013] The structure includes a wire sliding machine 1, a servo motor A2, a power controller 3, a wire sliding machine support rod 4, a slideway platform 5, a frame bracket 6, a material placement platform 7, a wire sliding machine bracket 8, a servo motor B1-1, Servo motor B transmission rod 1-2, cylinder group A1-3, cylinder group B1-4, cylinder group C1-5, pliers mouth 1-6, I-shaped spring 1-7, I-shaped spring seat 1-8, cutting saw Cylinder 1-9, cutting saw 1-10, servo motor A transmission rod 2-1, pulley 2-2, it is characterized in that the inner wall of the top of the frame support 6 is connected with one side of the slideway platform 5, and the slideway platform Slideways are set on 5, the pulleys 2-2 provided at both ends of the bottom of the wire sliding machine support rod 4 and the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com