Hydraulic type variable outer diameter cutting bed removing tool

A cleaning tool, hydraulic technology, applied in the direction of wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve problems such as limited range of action, collapse of soft ground, unfavorable drill string running and drilling, etc., to achieve The structural design is simple and reliable, the difficulty of lowering is reduced, and the effect of improving the efficiency of rock cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

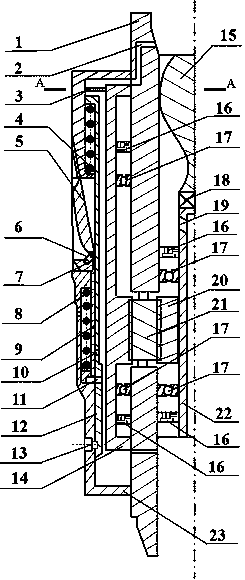

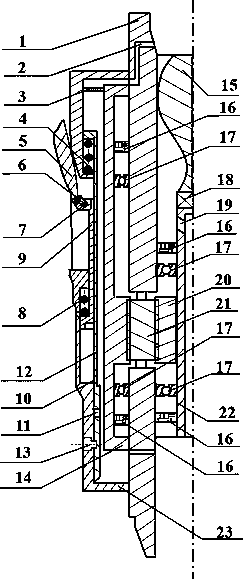

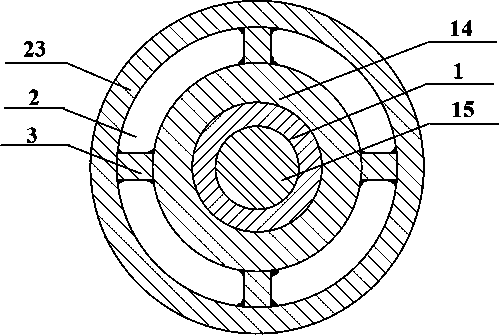

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] A hydraulic variable outer diameter cuttings bed removal tool, including a cylinder 23, an upper spring 4, a scraper 5, a connecting rod 6, a knife seat 7, a lower spring 8, a piston cylinder 9, a central tube 12, a sliding pin 13, Cross bar 3, side channel 2, sliding sleeve 14, housing 1, planetary gear 21, driving gear 20, screw rod 15, cardan shaft 18, central shaft 22, it is characterized in that, processing sliding sleeve 14 and The cylinder 23, the sliding sleeve 14 and the cylinder 23 are welded and connected by the cross bar 3, one end of the connecting rod 6 is hinged with the lower end of the scraper 5, and the other end of the connecting rod 6 is hinged with the hinge support outside the knife seat 7; The two hinge supports are respectively installed in the three grooves in the middle part of the cylinder body 23, the scraper 5 is installed on the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com