Double-brake disc type brake and automobile braking method

A technology of disc brakes and automobile brakes, which is applied in the direction of brake discs, brake types, axial brakes, etc., can solve the problems of affecting the service life of friction linings, excessive wear of friction linings, and poor braking performance, etc., to achieve Improve axial sliding ability, prolong life, reduce vibration and abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the claims, description and accompanying drawings disclosed in the present invention , those skilled in the art can easily understand the related objects and advantages of the present invention.

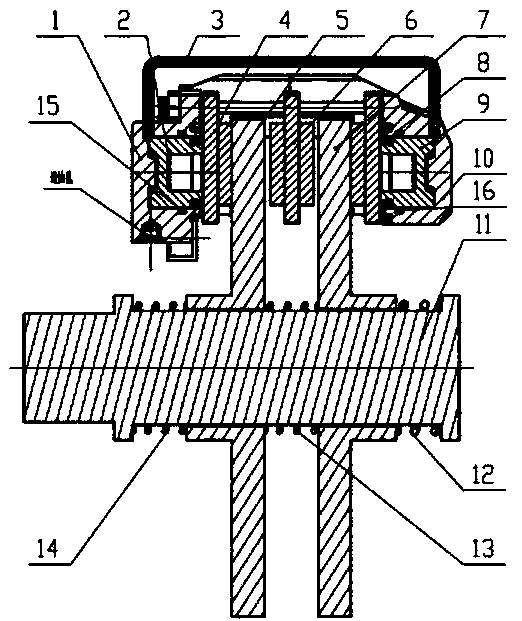

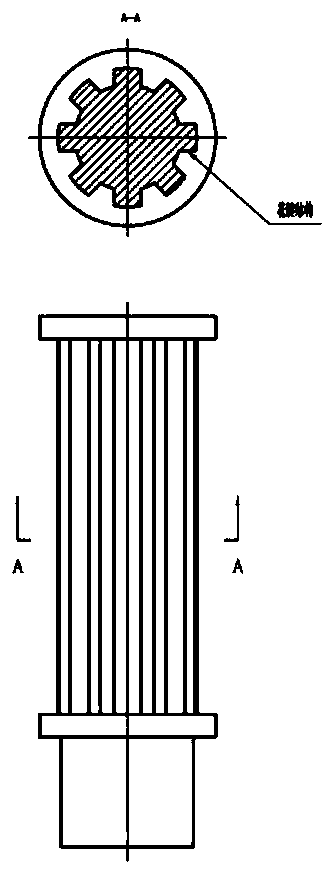

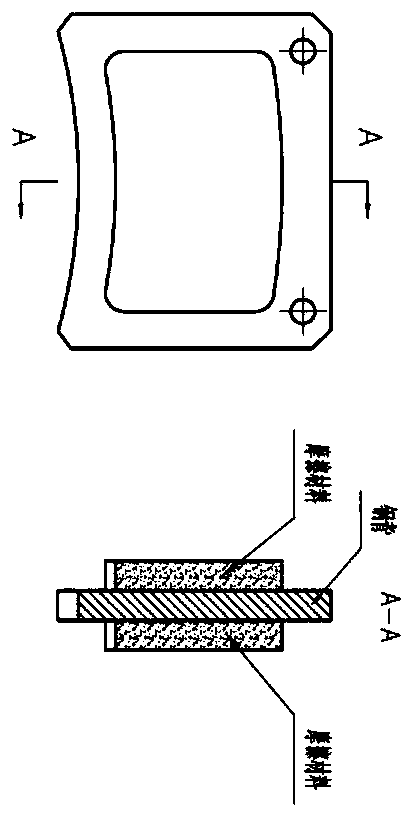

[0023] figure 1 Indicates the double brake disc brake assembly installed in the wheel of the motor vehicle, including the first brake disc (5), the second brake disc (7), the first friction plate (4), the second friction plate (8 ), a friction plate (6) with friction material on both sides, and a drive assembly that drives the friction plate to rub against the corresponding brake disc; the friction plate (6) with friction material on both sides is arranged on the first bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com