Pre-tightening device for eliminating transmission chain gaps

A transmission chain and clearance technology, which is applied in the direction of transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem that the long-term stability and precision retention of the feeding system cannot be guaranteed, and affect the transmission accuracy and machining accuracy of equipment or mechanisms. High requirements and other problems, to achieve the effect of low cost, small space occupation, simple processing technology and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

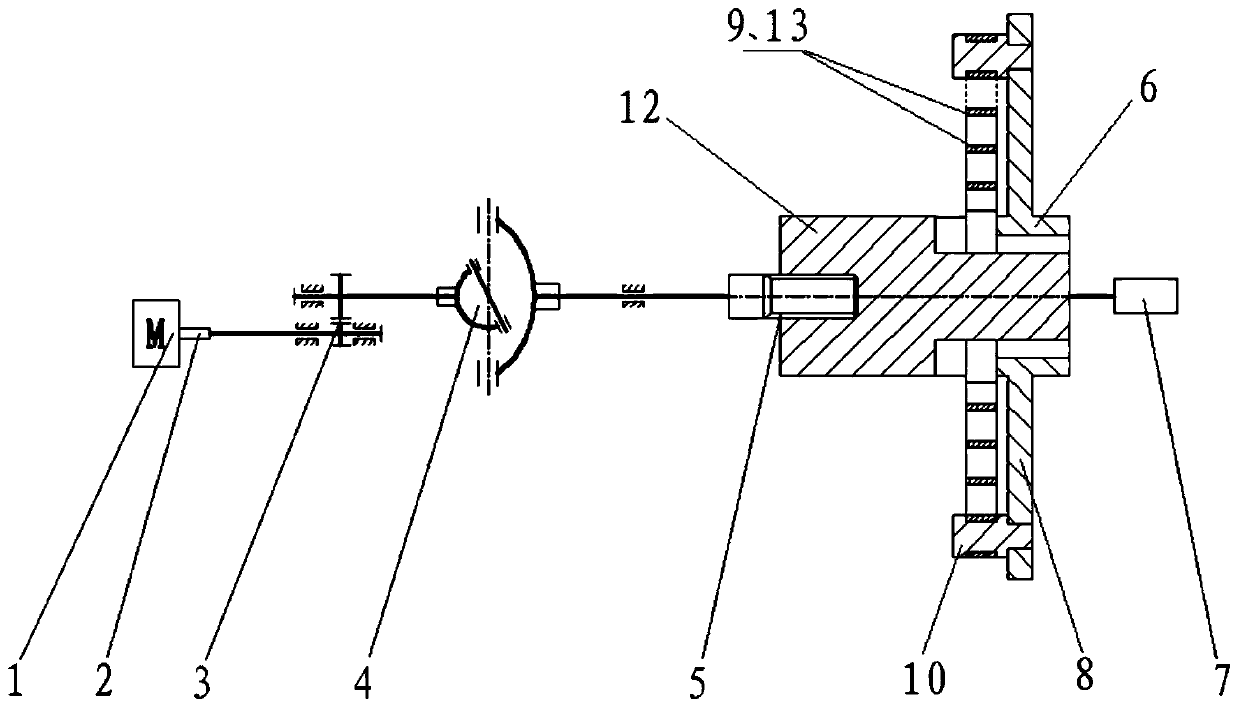

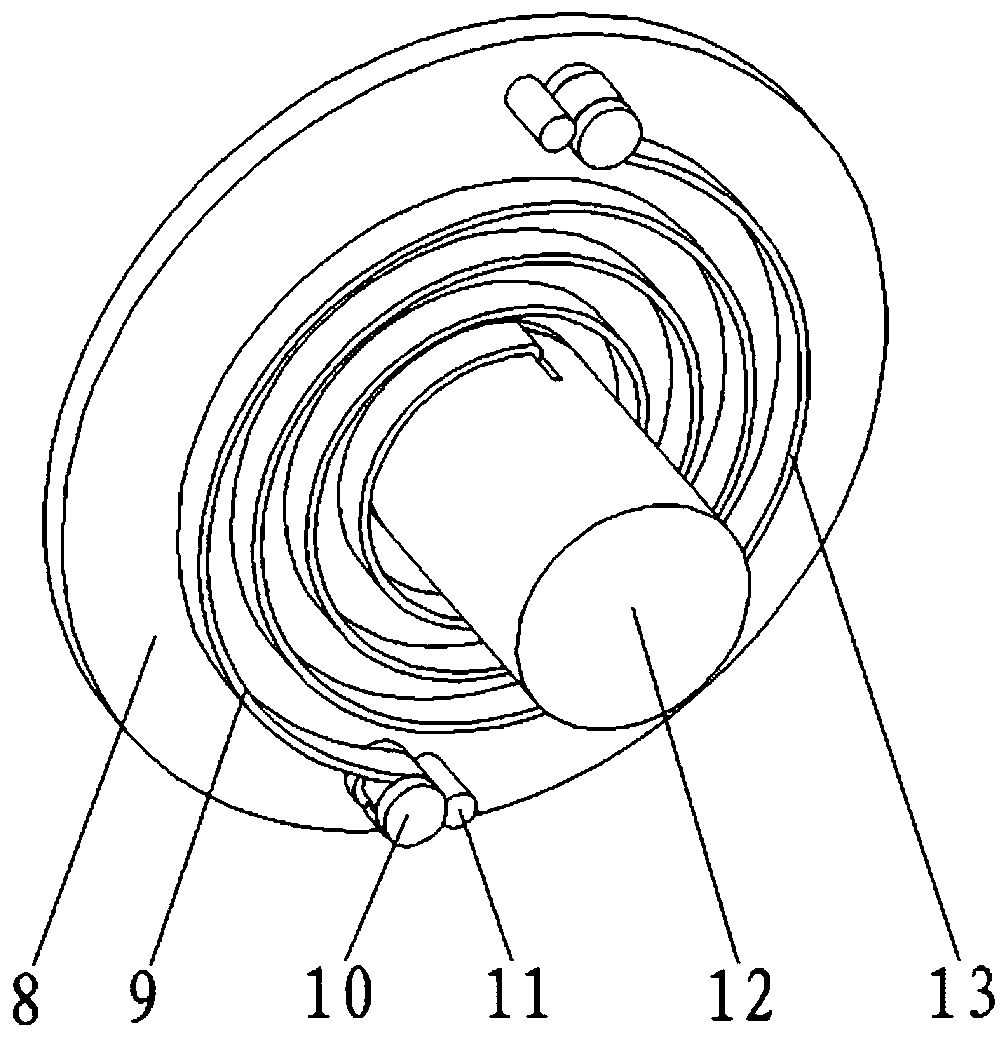

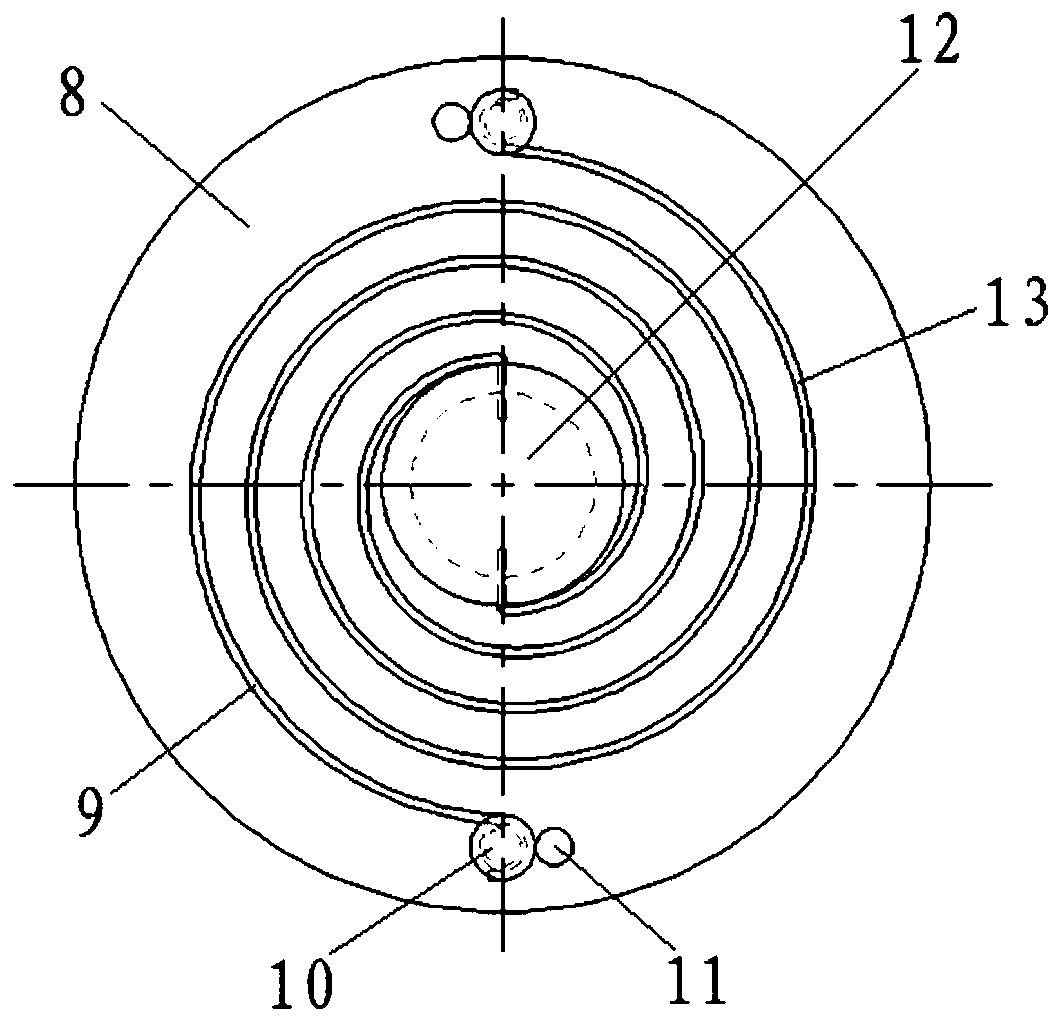

[0020] figure 1 It is a schematic diagram of the working principle of the transmission chain of the feed system. Generally, the transmission chain is powered by the output end 1 (such as a motor or other power source) and transmitted to the power output shaft 2. Through the gear pair 3, the universal joint 4 and the key 5 and other methods to realize the functions of transmission chain such as speed change or direction change, and finally transmit the power to the execution end 7 to complete the transmission of force or torque, but there is a meshing gap in the gear pair 3, a transmission gap in the universal joint 4, and the key 5 and the keyway There is a fit gap, which leads to an error between the actual rotation angle or position of the execution end 7 of the transmission chain and the power output shaft 2 of the feed system after multiple long-ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com