Preparation method of catalyst for methane reforming reaction by using carbon dioxide

A carbon dioxide and catalyst technology, applied in the field of catalyst preparation, can solve the problems of increasing catalyst cost and technical difficulty, demanding equipment requirements, etc., and achieve the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: take by weighing 13.7g ZrOCl 2 ·gH 2 O was prepared as a 0.17M aqueous solution, diluted 10 times with 25% ammonia water and placed in a beaker as a precipitant, and slowly dropped into ZrOCl under vigorous stirring 2 aqueous solution, and control the pH value of the solution to 10. After the dropwise addition, continue to stir for 0.5 hours, then age for 2 hours, filter, and wash with deionized water until there is no Cl - Then wash twice with absolute ethanol, after suction filtration or centrifugation, place the alcohol gel in a quartz tube, and pass N at a flow rate of 30ml / min at 270°C 2 Dry for 3 hours to produce ultrafine ZrO 2 carrier. Weigh a certain amount of Ni(NO 3 ) 2 ·6H 2 O, prepared as a 10% aqueous solution, with this Ni(NO 3 ) 2 Solution impregnation of 2g prepared ultrafine ZrO 2 The carrier, after stirring at room temperature for 2 hours, was rotary evaporated to dryness, and dried at 110°C for 12 hours. The dried sample was m...

Embodiment 2

[0015] Embodiment 2: Carrier ZrO 2 Preparation of Ni / ZrO 2 The preparation of catalyst and activity evaluation method are with embodiment 1, and difference is that alcohol gel is in N 2 The drying / calcination temperature in the atmosphere was 650°C. The reaction results showed that the initial conversion rates of methane and carbon dioxide were 84.2% and 85.9% respectively, and the catalyst was used continuously for 200 hours without any decline in activity.

Embodiment 3

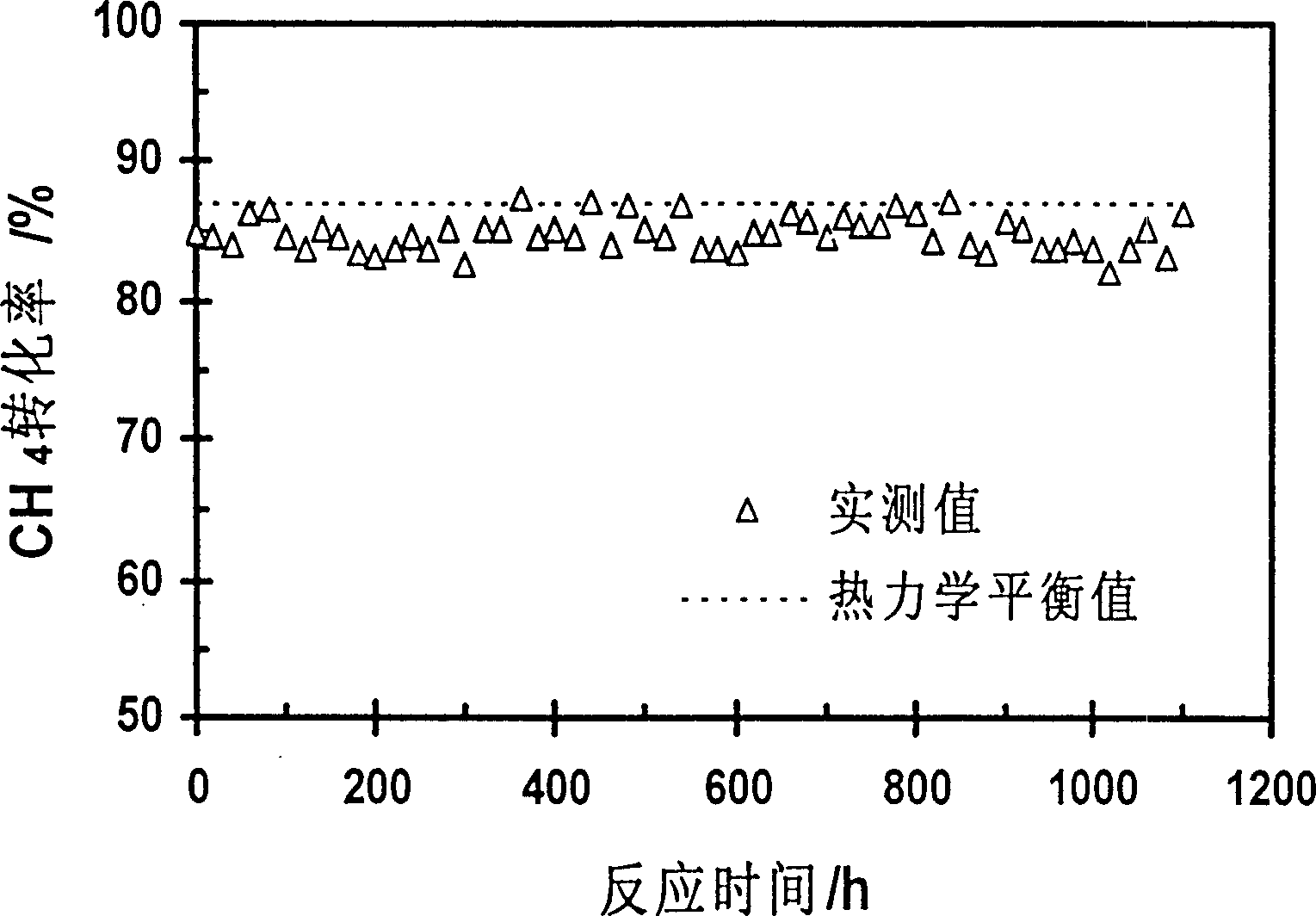

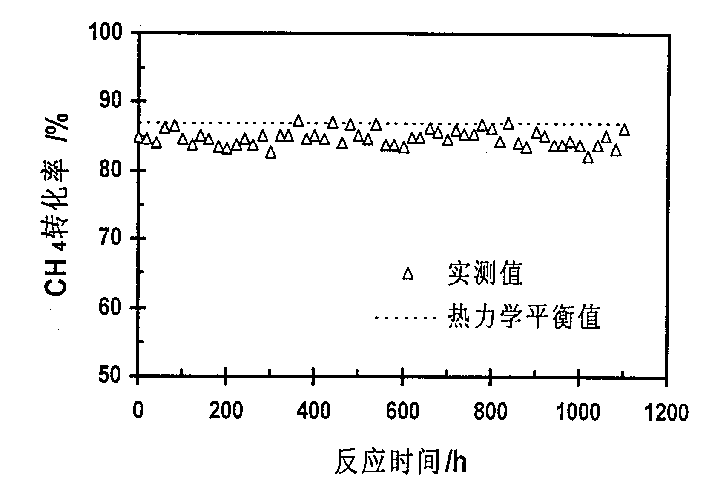

[0016] Embodiment 3: Carrier ZrO 2 Preparation of Ni / ZrO 2 The preparation of catalyst and activity evaluation method are with embodiment 1, and difference is that alcohol gel is in N 2 The drying / calcination temperature in the atmosphere was 350°C. The reaction results show that the initial conversion rate of methane and carbon dioxide is close to the equilibrium conversion, and the catalyst has been used continuously for 1100 hours without any decline in activity. The relationship curve of the conversion rate of methane over time is shown in the attached figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com