High-temperature alkali metal heat pipe hot-state filling loop system and method

A loop system and alkali metal technology, which is applied in the field of high temperature alkali metal heat pipe hot filling loop system, can solve the problems of being reported or disclosed, and the manufacturing process is not mature enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

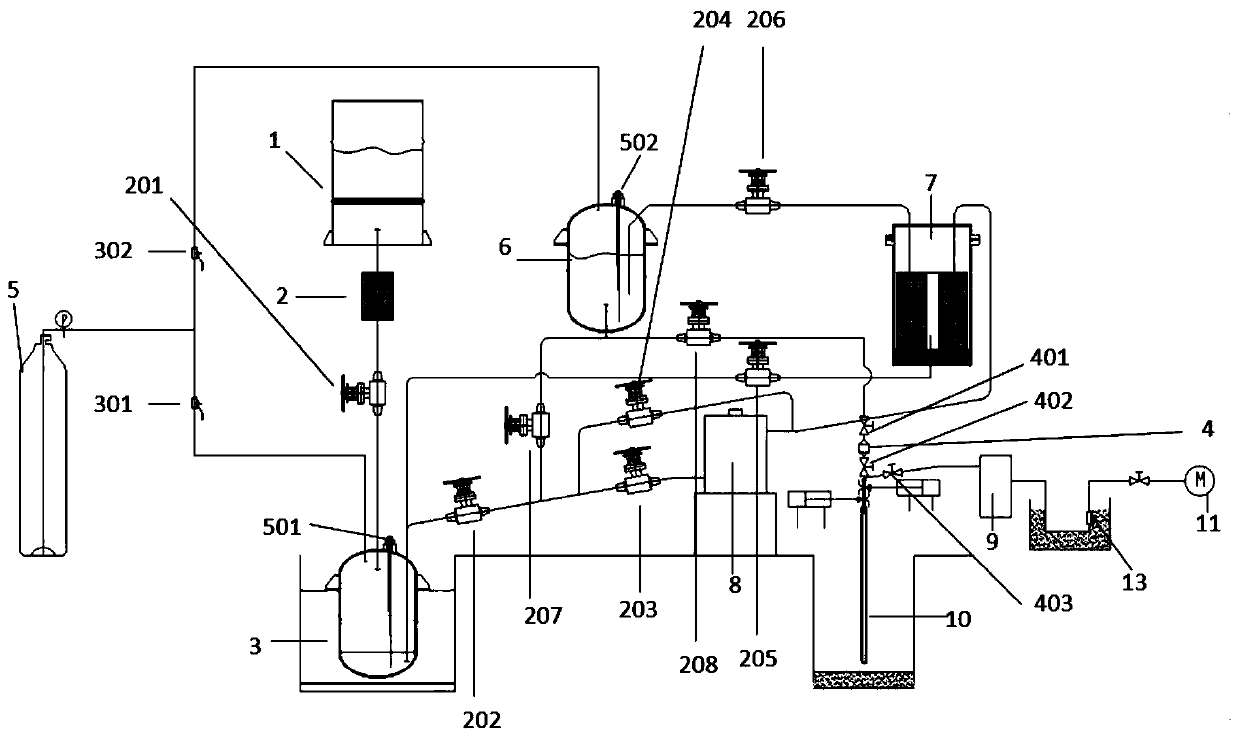

[0018] Such as figure 1 As shown, the present invention proposes a high-temperature alkali metal heat pipe thermal filling loop system, including an alkali metal melting tank 1, the bottom of the alkali metal melting tank 1 is connected to the filter 2 through a stainless steel pipeline, and the bottom of the filter 2 passes through the pipeline and the first alkali The metal valve 201 is connected to the first alkali metal storage tank 3, and the first alkali metal storage tank 3 is connected to the inlet of the electromagnetic pump 8 through the pipeline, the second alkali metal valve 202 and the third alkali metal valve 203, and bypass valves are arranged at both ends of the electromagnetic pump 8. The bypass pipeline is provided with a fourth alkali metal valve 204 to control the flow, the outlet of the electromagnetic pump 8 is connected to the cold trap 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com