Germ rice processing system and method

A processing system and germ rice technology, applied in grain processing, agriculture, application, etc., can solve the problems of insufficient grinding, clogging, lack of cleaning, draining and air-drying, etc., to achieve good separation effect and increase efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

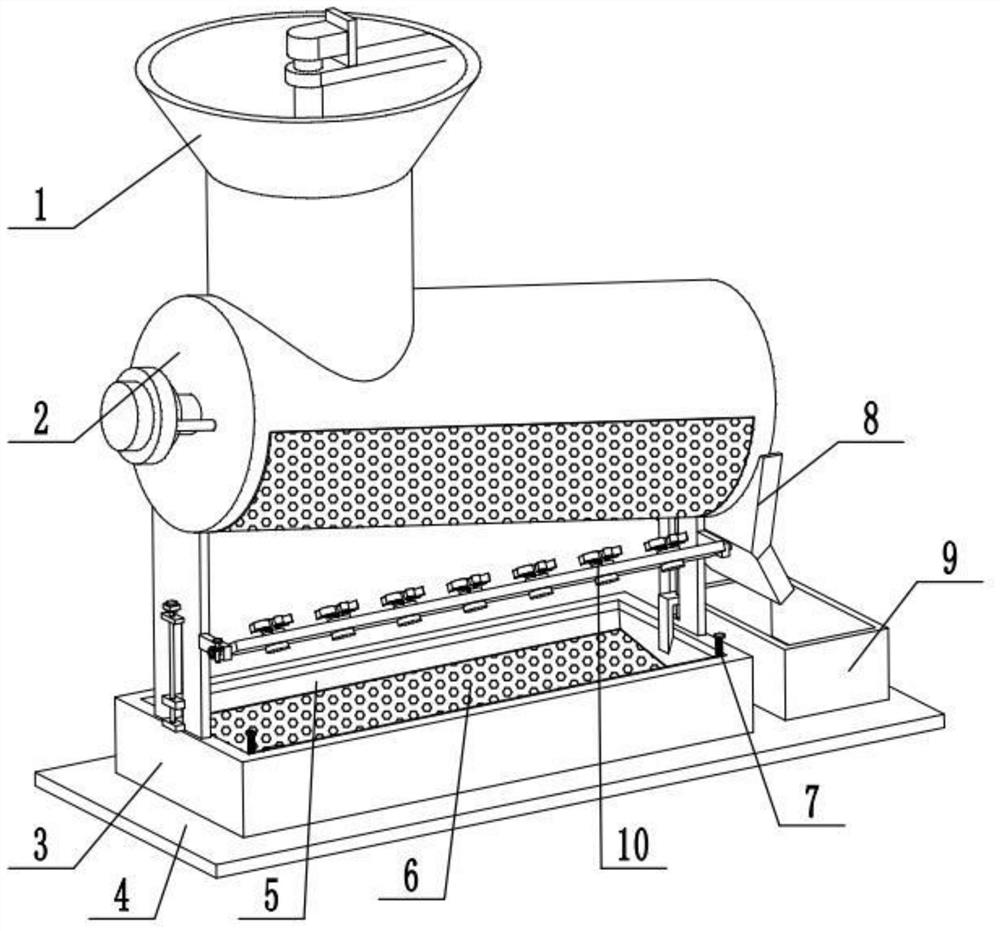

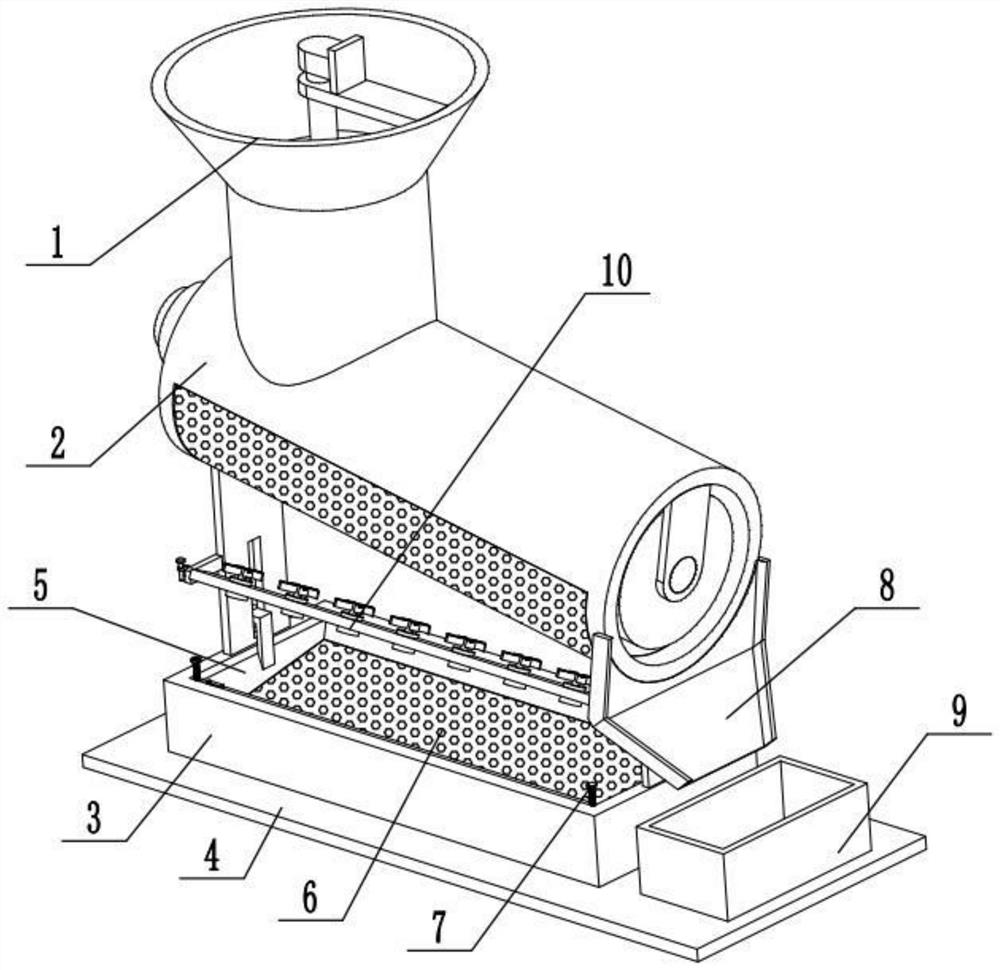

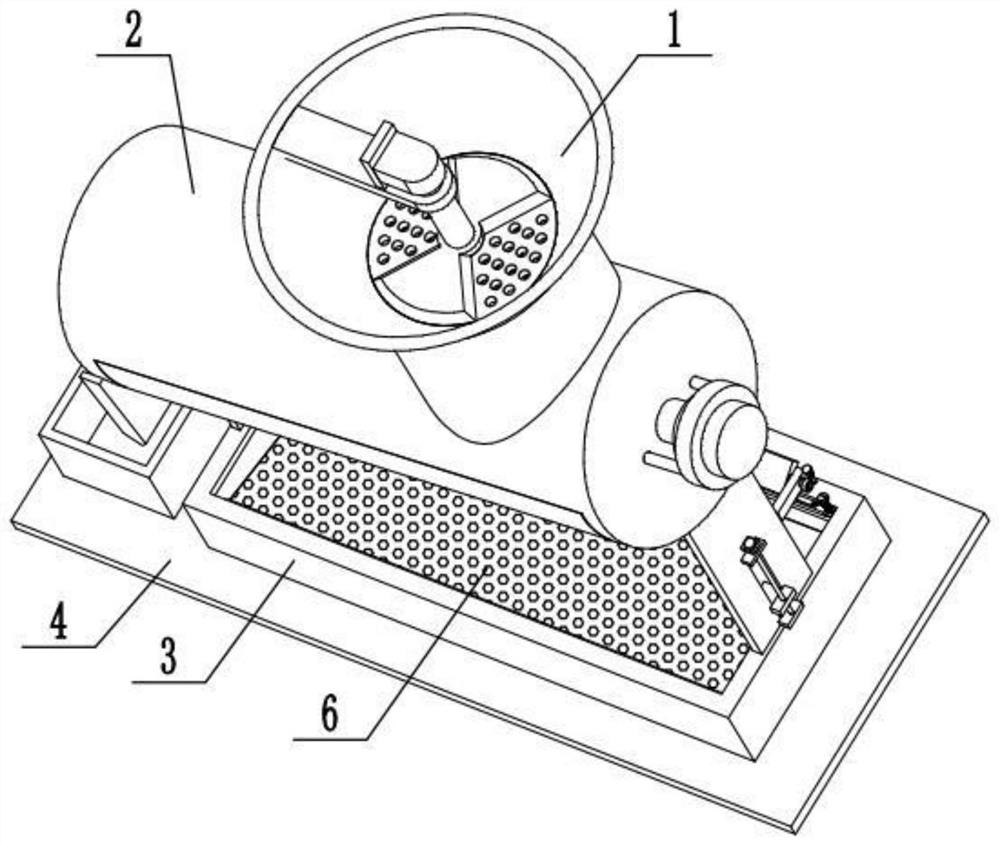

[0047] Combine below Figure 1-19 Describe this embodiment, a germ rice processing system, including a feeding mechanism 1, a grinding mechanism 2, a cleaning tank assembly 3, a bottom plate 4, a draining assembly 5, a feeding bottom plate 6, a baffle assembly 7, a hopper 8, and a collection box 9 and the fan mechanism 10, the feeding mechanism 1 is fixedly connected to the grinding mechanism 2, the grinding mechanism 2 is fixedly connected to the cleaning tank assembly 3, the cleaning tank assembly 3 is fixedly connected to the bottom plate 4, and the draining assembly 5 is arranged on the cleaning tank On the assembly 3, the feeding bottom plate 6 is slidingly fitted and connected in the draining assembly 5, the baffle assembly 7 is arranged on the front end of the draining assembly 5, the front end of the feeding bottom plate 6 leans against the baffle assembly 7, and the guide hopper 8 is fixedly connected to the feeding At the right end of the mechanism 1, the collection ...

specific Embodiment approach 2

[0049] Combine below Figure 1-19 To illustrate this embodiment, the feeding mechanism 1 includes a conical feeding seat 1-1, a blanking seat 1-2, a blanking tray 1-3, a horizontal frame plate 1-4, a motor I1-5, and a driving shaft 1-6, intermittent baffle plate 1-7, grinding part Ⅰ 1-8 and grinding part Ⅱ 1-9; the conical feeding seat 1-1 is fixedly connected to the blanking seat 1-2, and the blanking seat 1- 2. It is fixedly connected and connected to the grinding mechanism 2. The connection between the conical feeding seat 1-1 and the blanking seat 1-2 is fixedly connected to the blanking plate 1-3. The horizontal shelf plate 1-4 is fixedly connected to the conical feeding On the upper end of the seat 1-1, the motor Ⅰ1-5 is fixedly connected to the horizontal frame plate 1-4 through the motor frame, the output shaft of the motor Ⅰ1-5 is connected to the driving shaft 1-6 through the coupling, and the driving shaft 1-6 is passed through the belt The seat bearing is rotatabl...

specific Embodiment approach 3

[0051] Combine below Figure 1-19 To illustrate this embodiment, the grinding mechanism 2 includes an inner emery roller 2-5, a vertical frame plate 2-2, a motor II 2-3, a central shaft 2-4, and an outer emery roller 2-1; the inner emery roller 2-5 Inclined downward from left to right, the blanking seat 1-2 is fixedly connected and connected to the left end of the outer sand roller 2-1, the outer sand roller 2-1 is fixedly connected to the cleaning tank assembly 3, and the right end of the inner sand roller 2-5 Fixedly connected to the vertical frame plate 2-2, the motor II 2-3 is fixedly connected to the left end of the inner sand roller 2-5 through the motor frame, the output shaft of the motor II 2-3 is connected to the central shaft 2-4 through a coupling, and the central shaft 2- The two ends of 4 are respectively connected to the inner emery roller 2-5 and the central shaft 2-4 through bearings with seats, the outer emery roller 2-1 is fixedly connected to the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com