Sound insulation waste cotton waste sorting and recycling device

A technology for recycling devices and wastes, which is applied in the fields of removing smoke and dust, cleaning methods and utensils, and grain processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

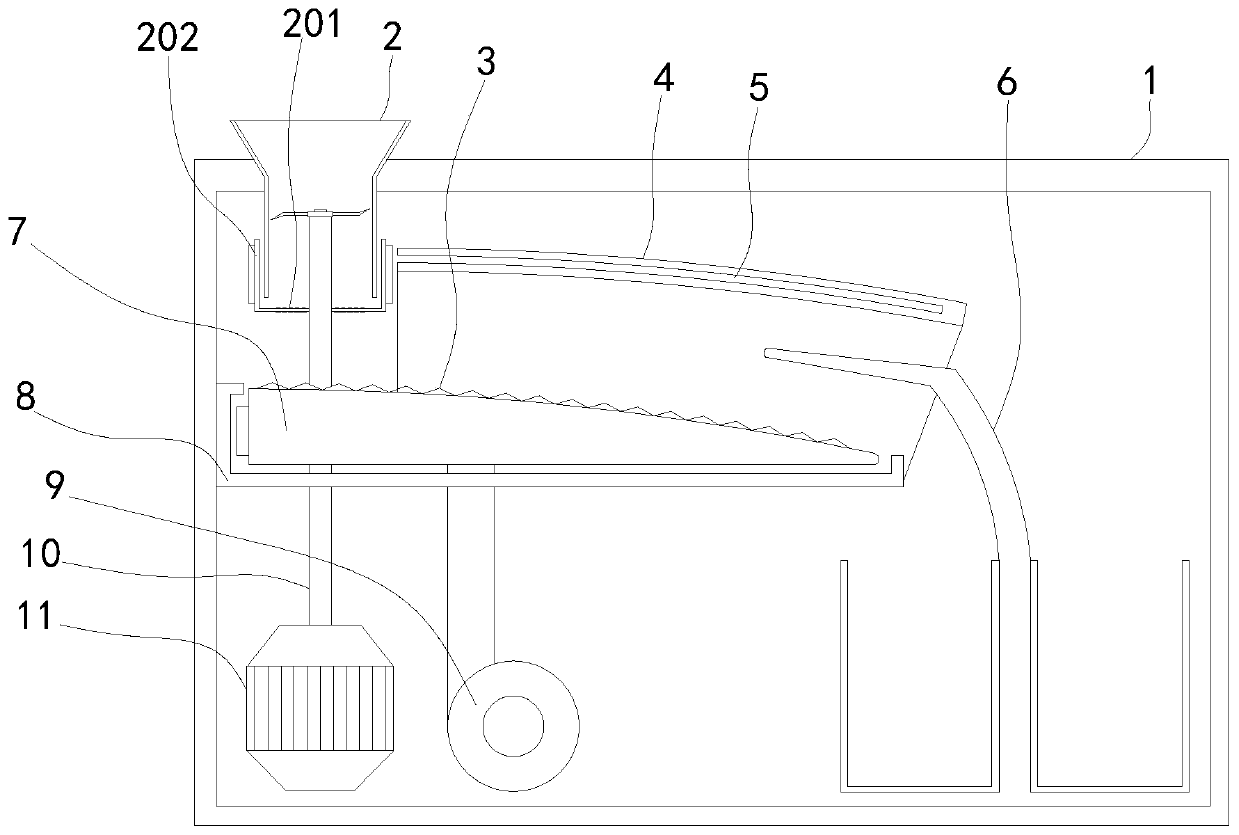

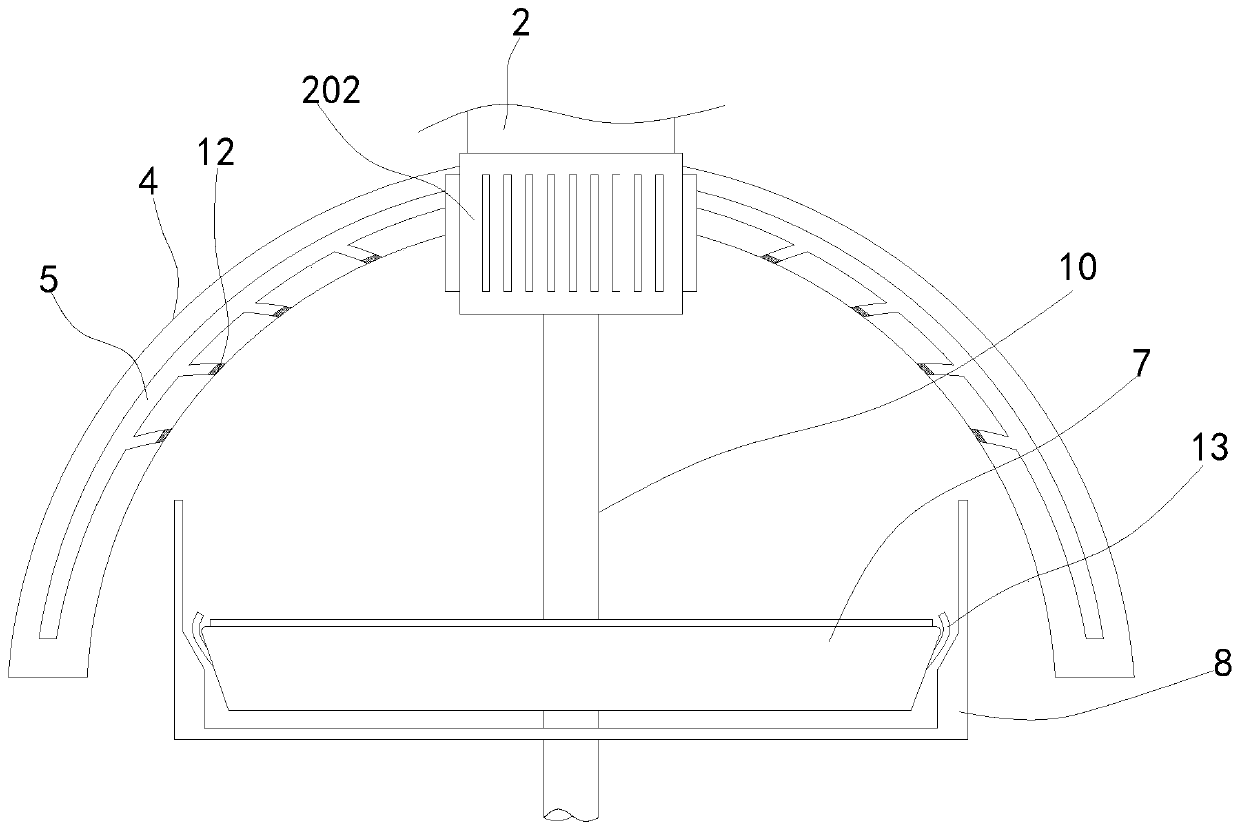

[0026] see Figures 1 to 8 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a device for sorting and recycling soundproof waste cotton waste.

[0027] A device for sorting and recovering sound-insulating waste cotton and waste, comprising a device main body 1 and a feeding channel 2. A vibrating plate 7 is fixedly connected to the inside of the device main body 1, and a dust cover 4 is fixedly installed on the right side of the material feeding channel 2.

[0028] In a specific implementation, a motor 11 is movably installed on the lower end of the main body 1 of the device, and a rotating rod 201 is fixedly connected to the upper end of the motor 11. The two ends of the rotating rod 201 are fixedly connected to a rotating layer 202 and the rotating layer 202 is sleeved on the outside of the feeding channel 2, so that The motor 11 can drive the rotating layer 202 to rotate through the rotating rod 201 while driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com