A preparation method of multi-grain scale multi-layer high-entropy alloy

A high-entropy alloy and entropy alloy technology, which is applied in the field of preparation of multi-grain-scale multilayer high-entropy alloys, can solve the problems of poor heat resistance, inability to synthesize the properties of various high-entropy alloys, and inability to control the cost of high-entropy alloys. Achieve the effect of good heat resistance and large microstructure design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

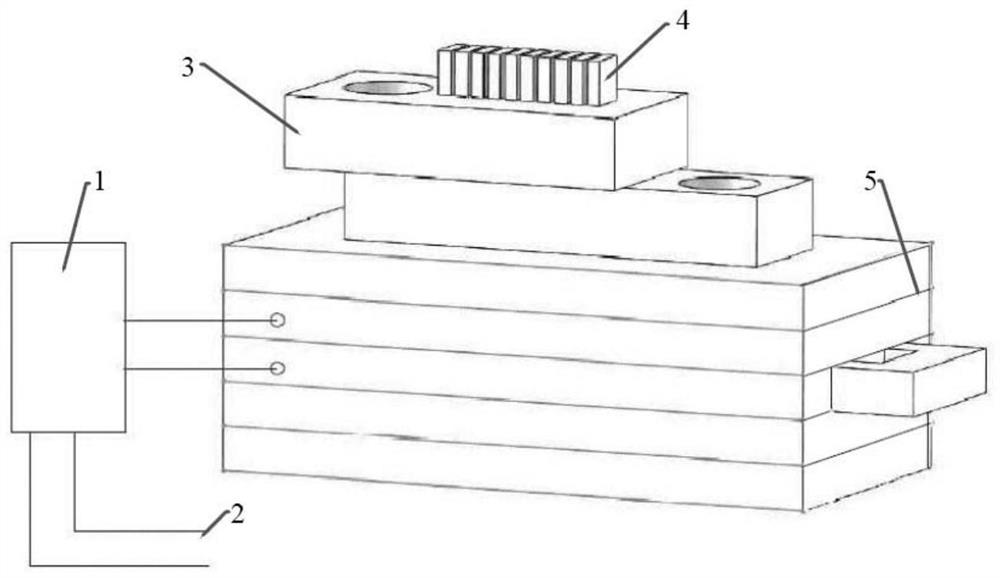

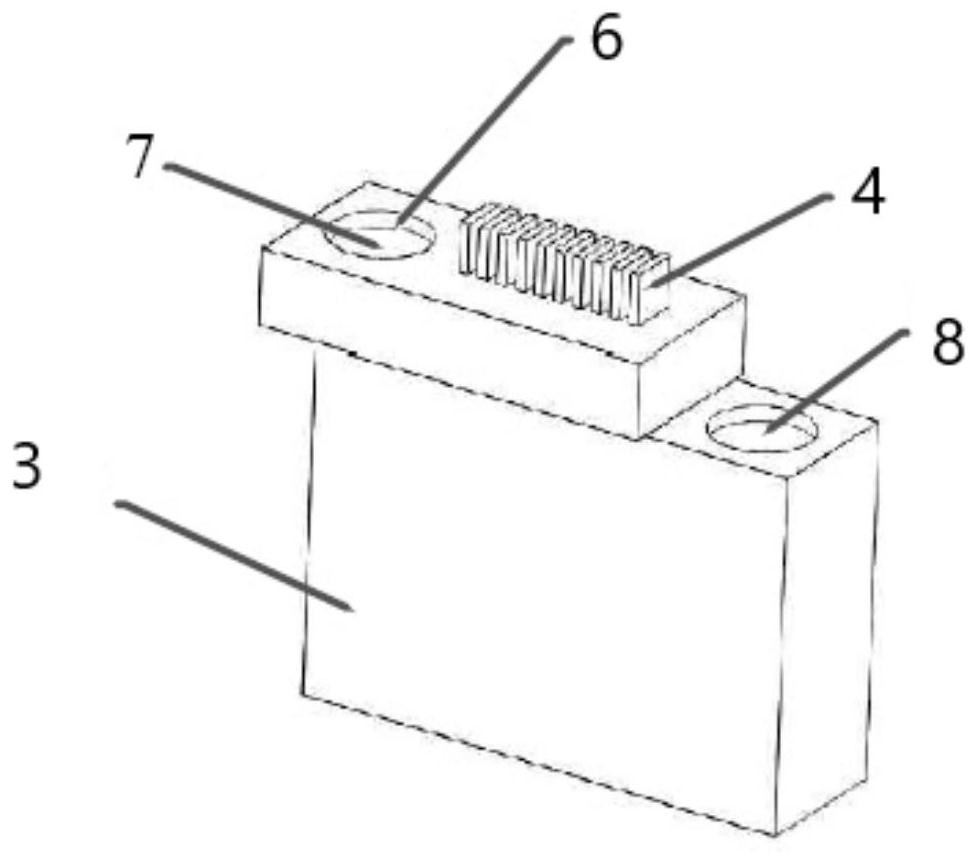

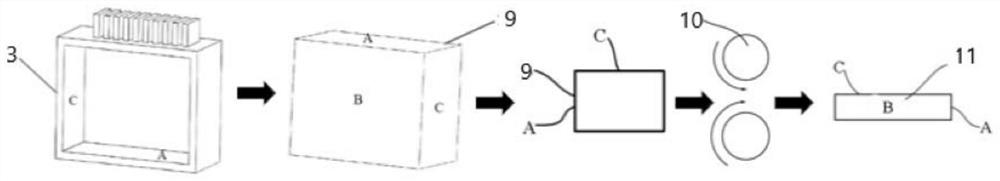

[0040] Such as Figure 1-4 As shown, the solid HfNbTaTiZr high-entropy alloy and the liquid CoCrFeMnNi high-entropy alloy are taken as examples, and detailed implementation methods and specific operations are given. Because the HfNbTaTiZr high-entropy alloy is a refractory high-entropy alloy with a body-centered cubic structure, its melting point is above 1500°C, and it shows good thermal stability below 900°C. The tensile strength in the as-cast state is 1GPa, but the uniform elongation The ratio is only 14%; while the CoCrFeMnNi high-entropy alloy is a high-entropy alloy with a face-centered cubic structure, the tensile strength in the as-cast state is only 500MPa, and the uniform elongation is 52%. The following examples involve a four-step process comprising: pretreatment, pouring, rolling, and multi-grain size formation, wherein:

[0041] Such as figure 1 As shown, the surface of the solid HfNbTaTiZr high-entropy alloy is cleaned by an ultrasonic instrument to remove oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com