Patents

Literature

46results about How to "Meeting the needs of industrial applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

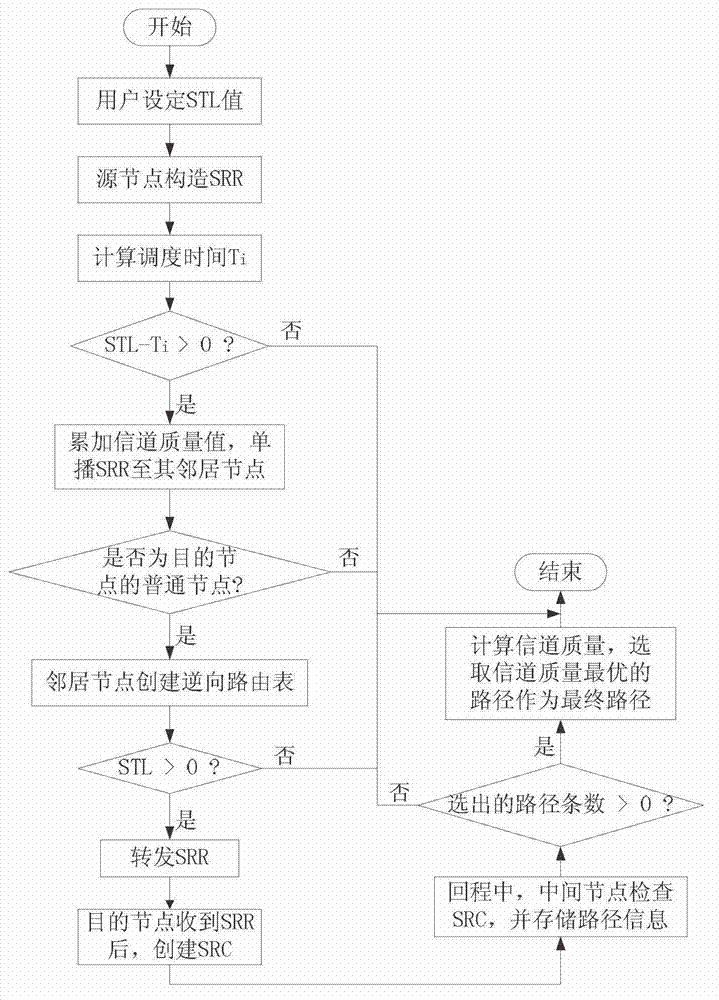

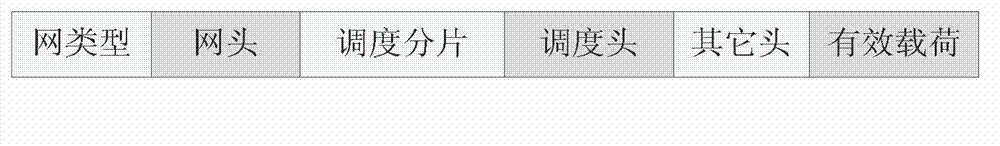

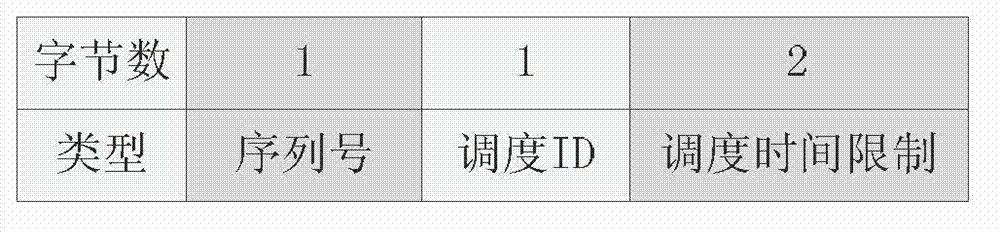

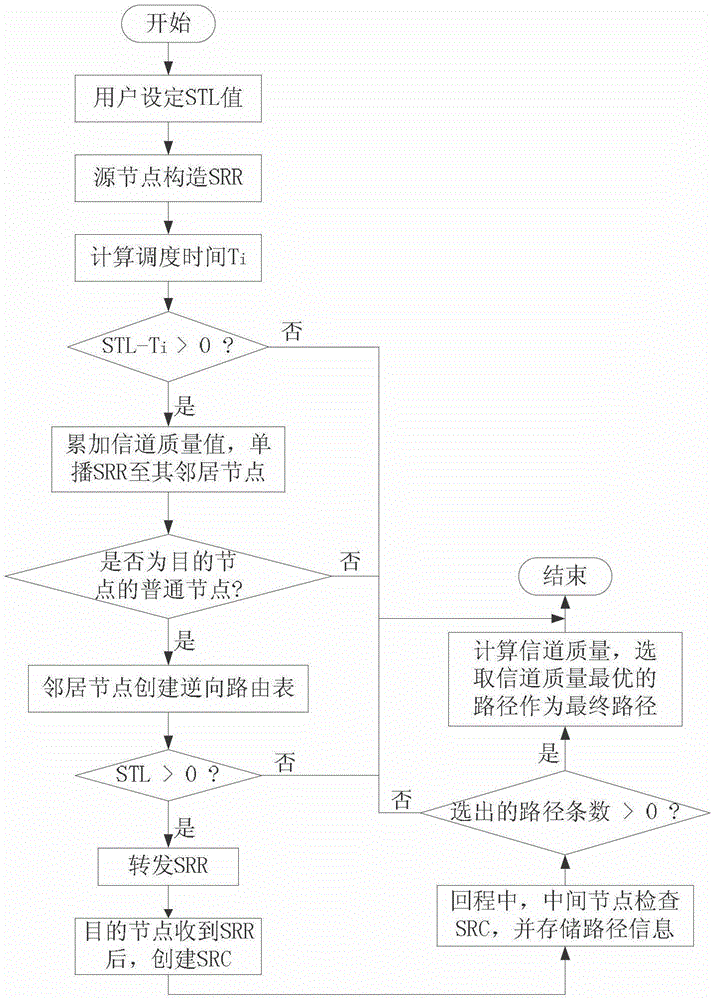

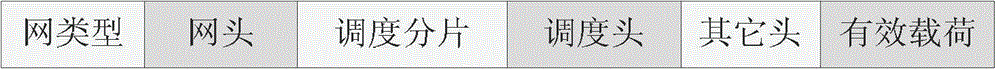

IPv6 (Internet protocol version 6) industrial wireless sensor network routing method based on definiteness scheduling

ActiveCN103118413AImprove communication performanceMeeting the needs of industrial applicationsNetwork topologiesInternet protocol suiteWireless sensor networking

The invention relates to an IPv6 (Internet protocol version 6) industrial wireless sensor network routing method based on definiteness scheduling and belongs to the technical field of industrial wireless sensor networks. The method is based on 6LoWPAN and definiteness scheduling of industrial wireless sensor networks, and adaptation layer protocol and neighbor discovery protocol are modified according to 6LoWPAN serial protocol standards. Scheduling time and channel quality are used as path selection standards according to application requirements of industrial wireless sensor networks. An optimal path simultaneously satisfying two routing standards is selected for data with marked definiteness features in a distributed manner, and accordingly definiteness, instantaneity and reliability requirements of industrial application are met. By the method, definiteness of an industrial wireless sensor network can be guaranteed effectively, and overall communication performance of the network is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

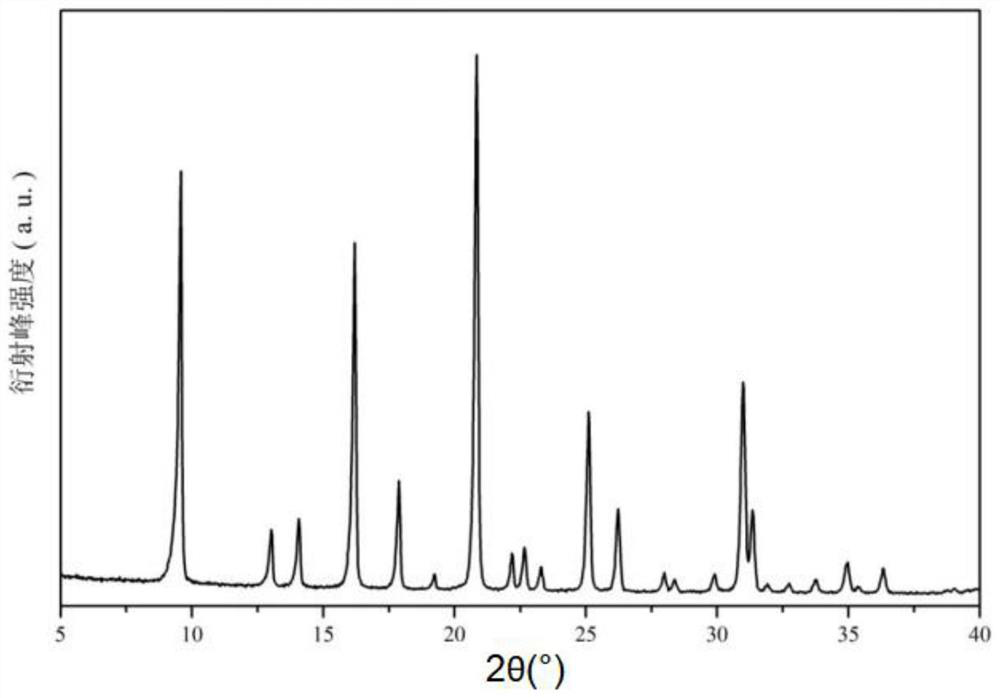

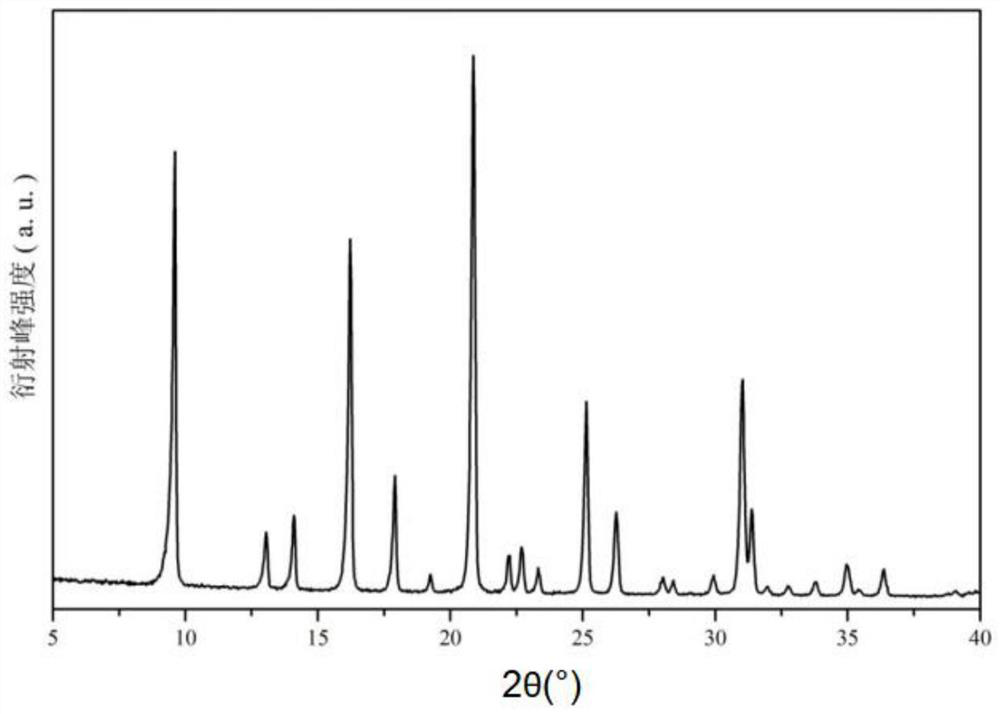

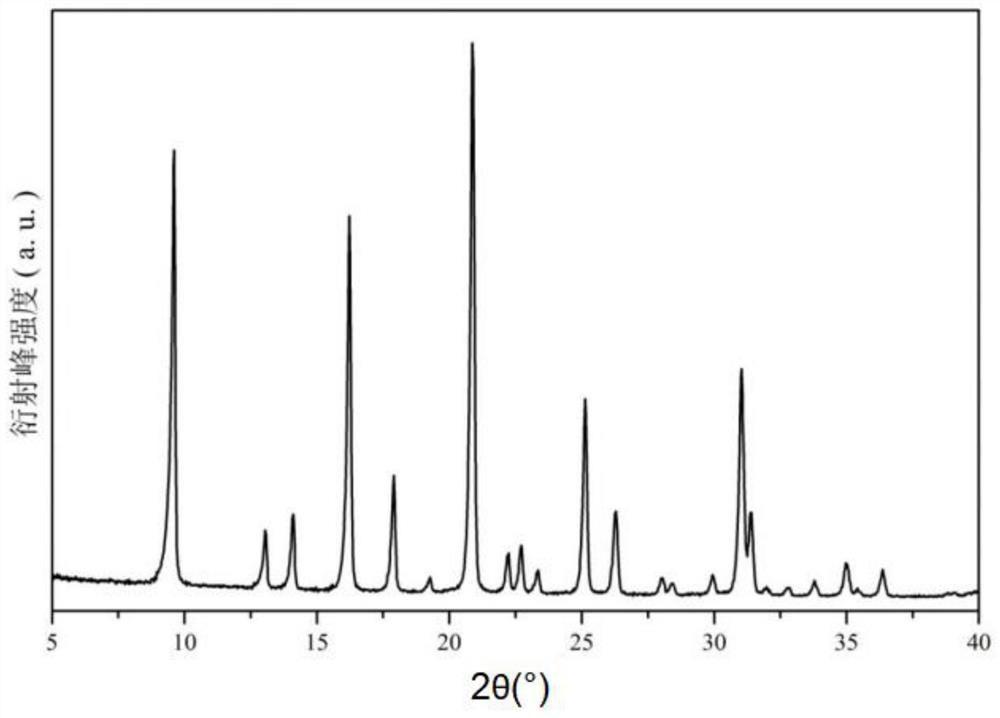

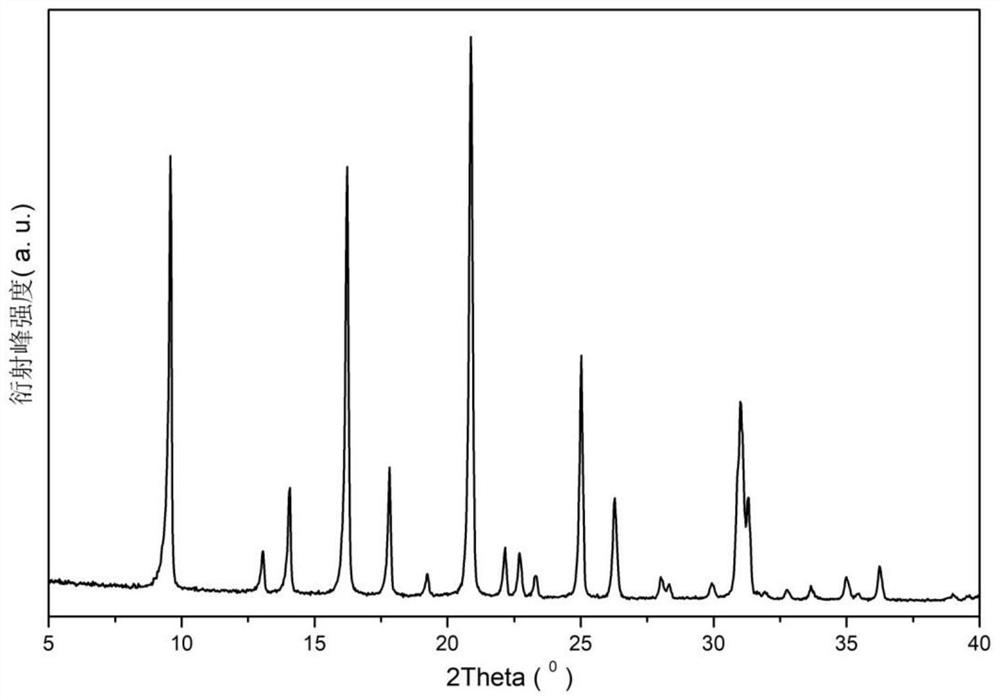

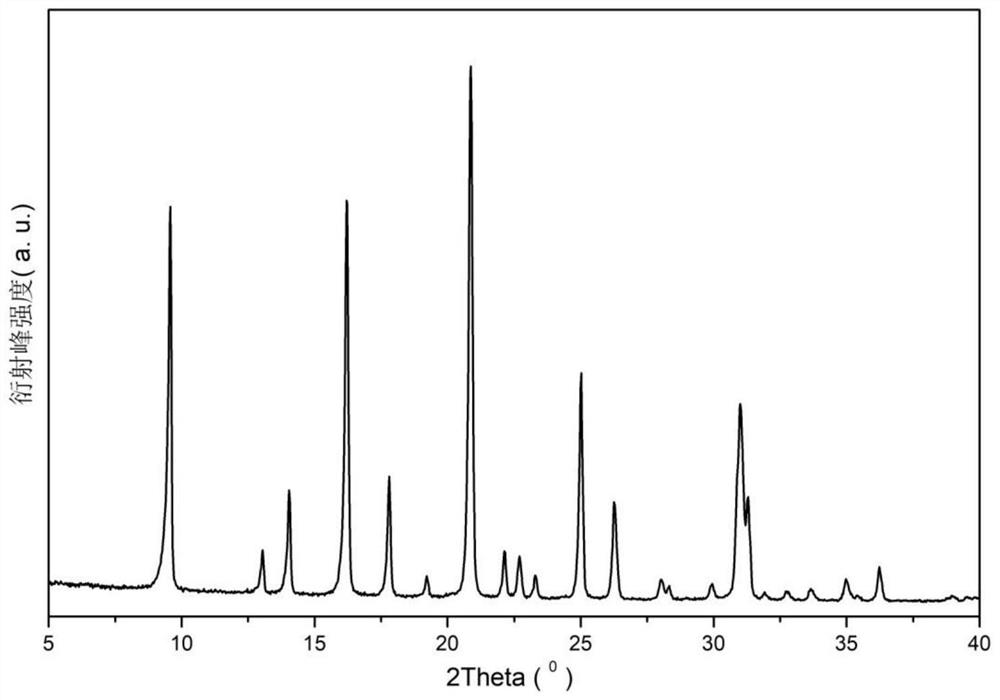

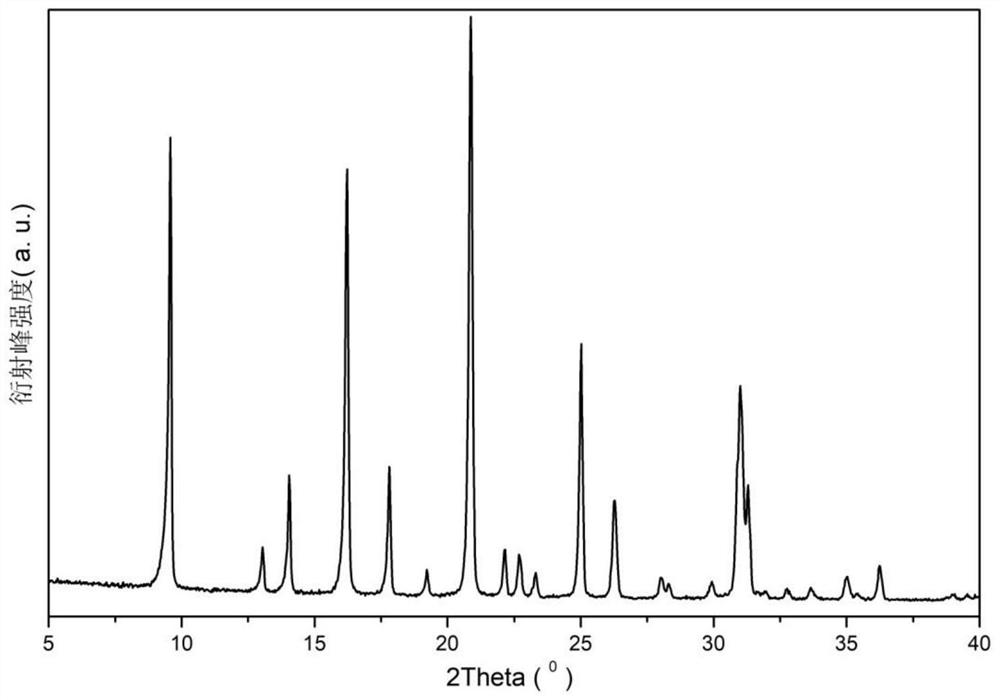

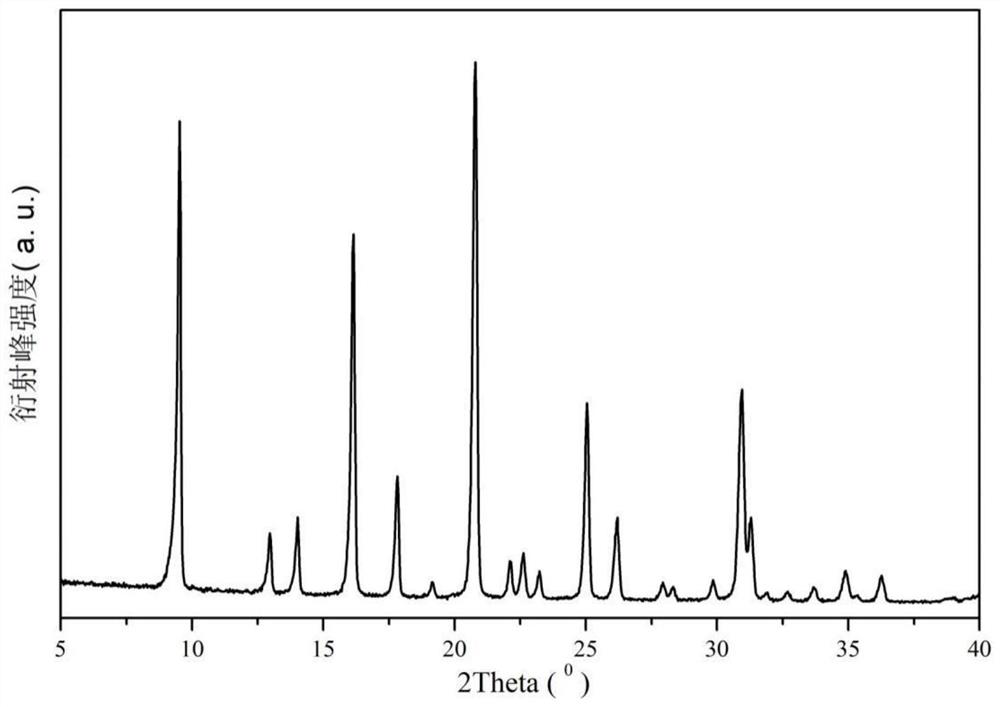

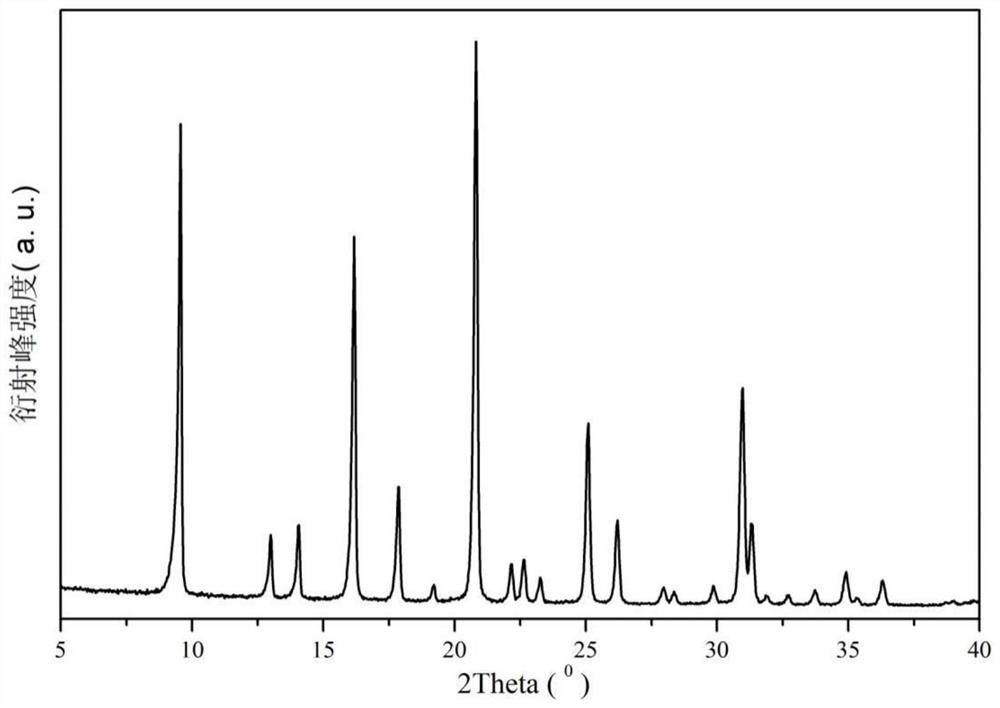

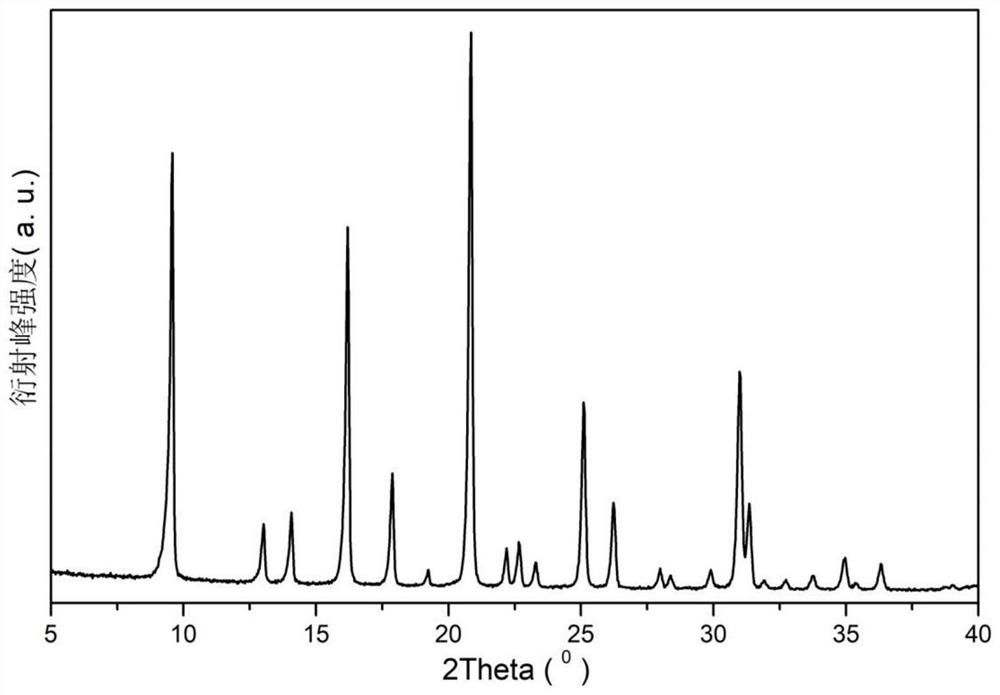

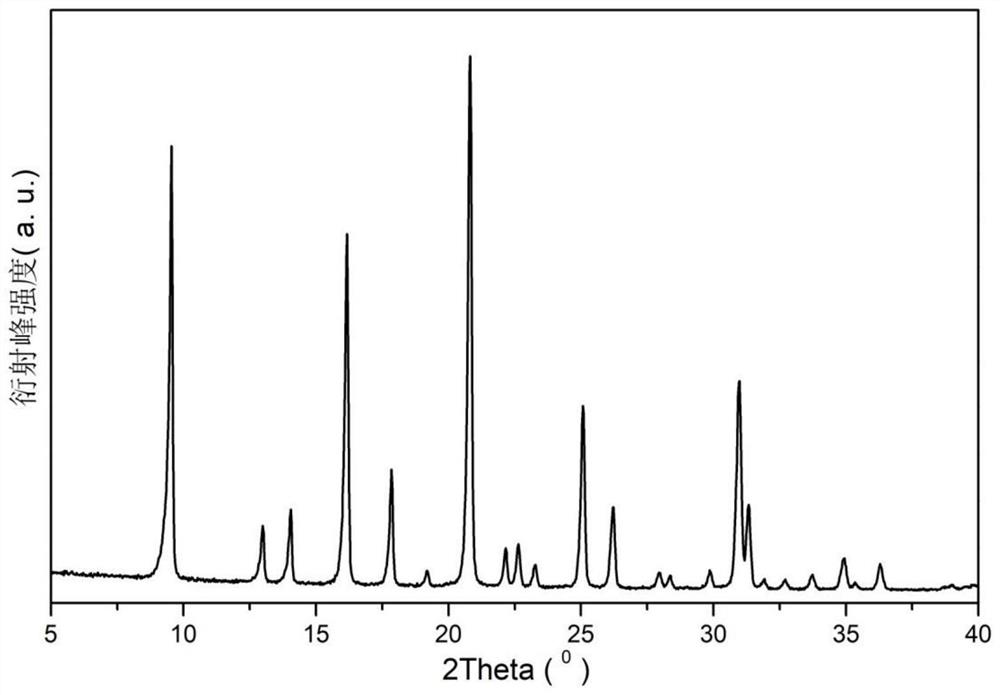

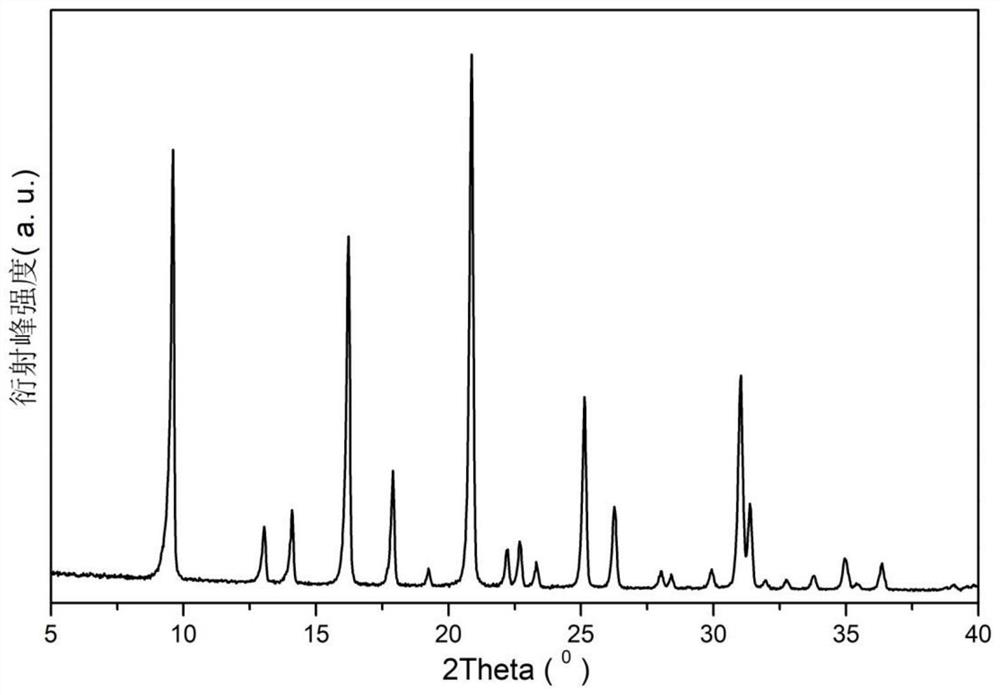

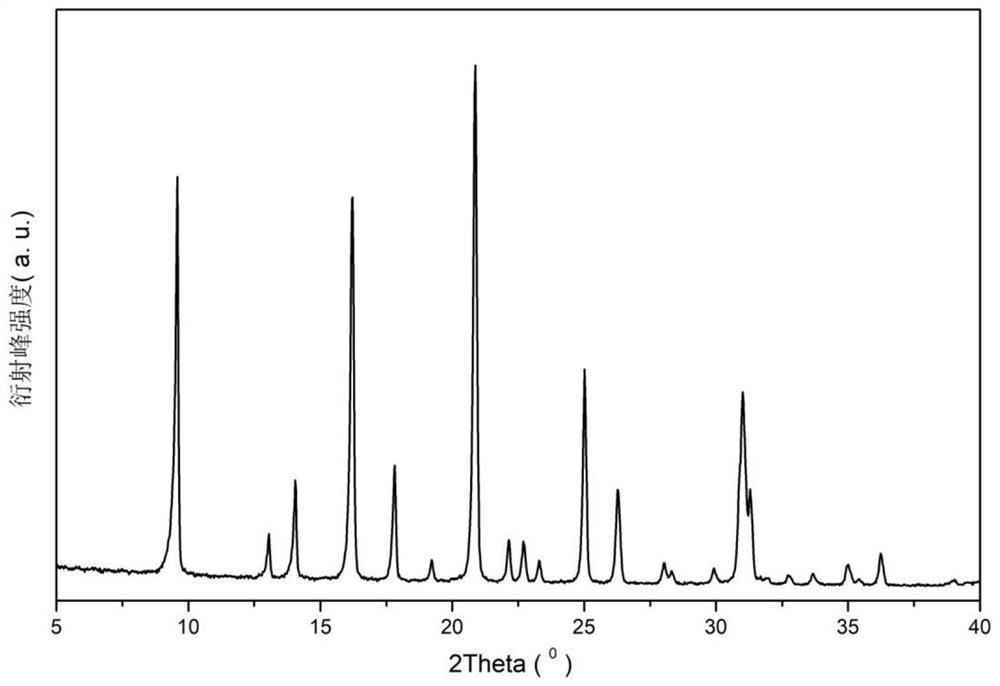

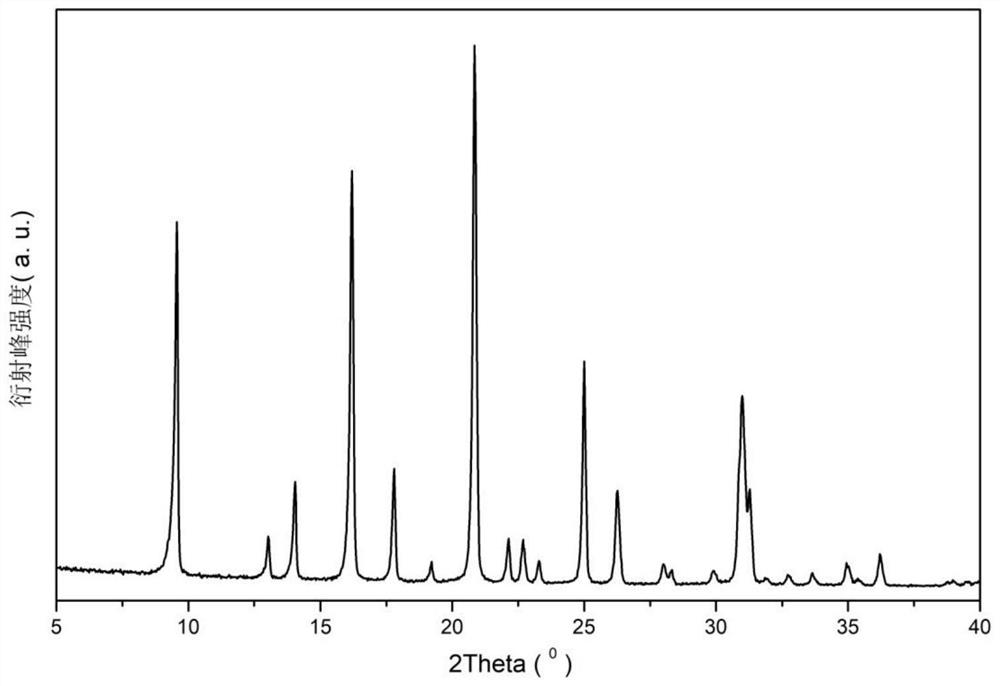

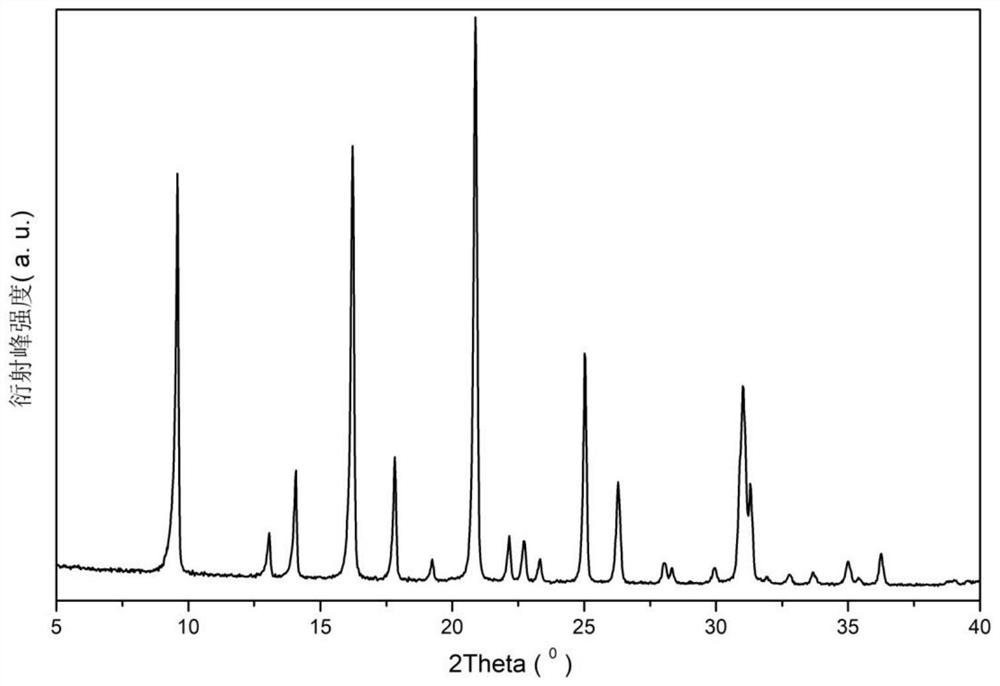

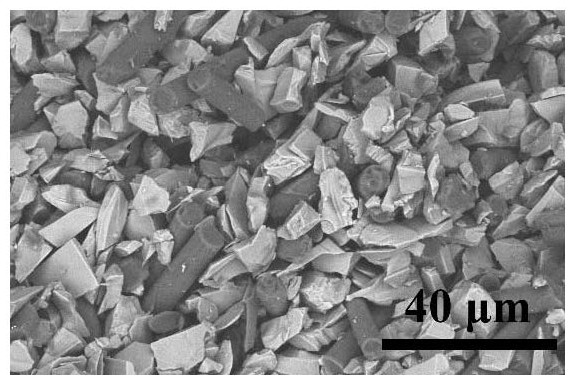

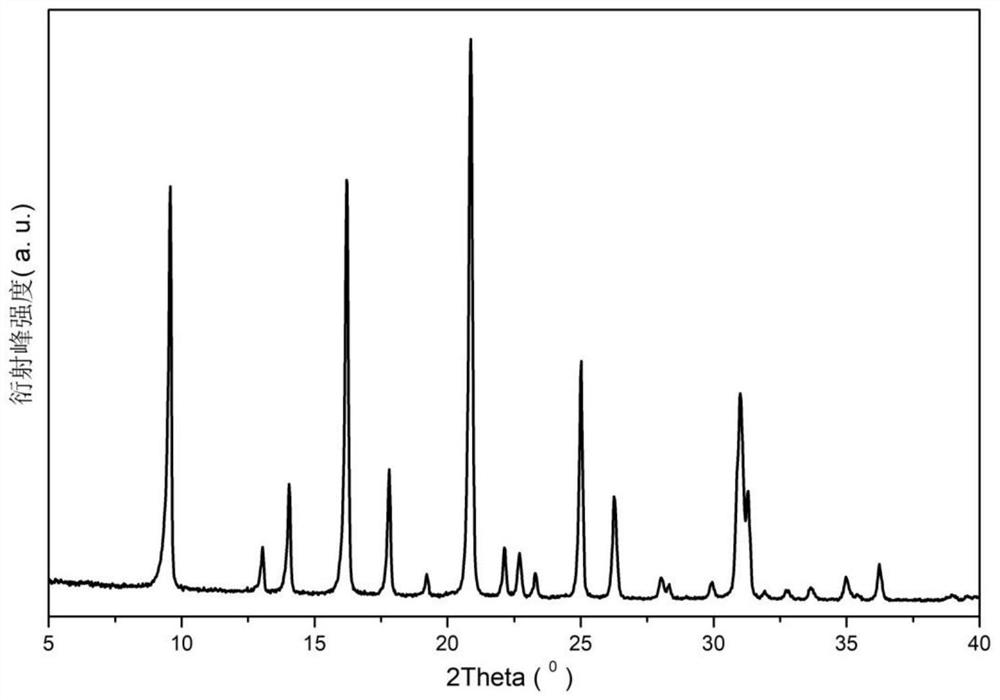

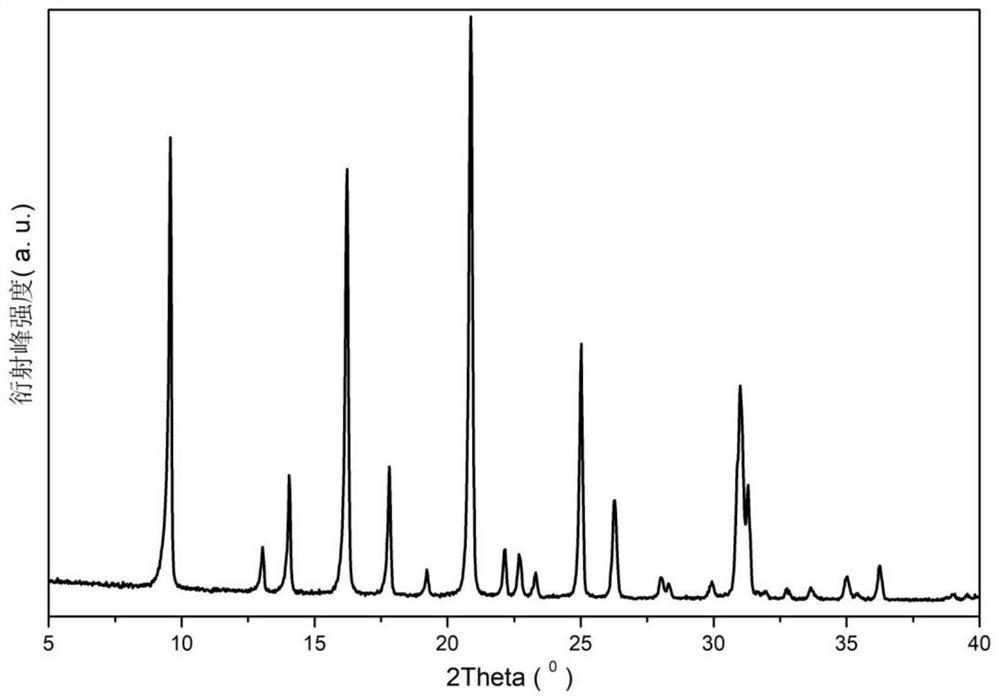

CHA molecular sieve, synthesis method thereof, catalyst synthesized by using CHA molecular sieve and application

ActiveCN112429746AHigh hydrothermal stabilityImprove recovery characteristicsMolecular sieve catalystsInternal combustion piston enginesMolecular sievePtru catalyst

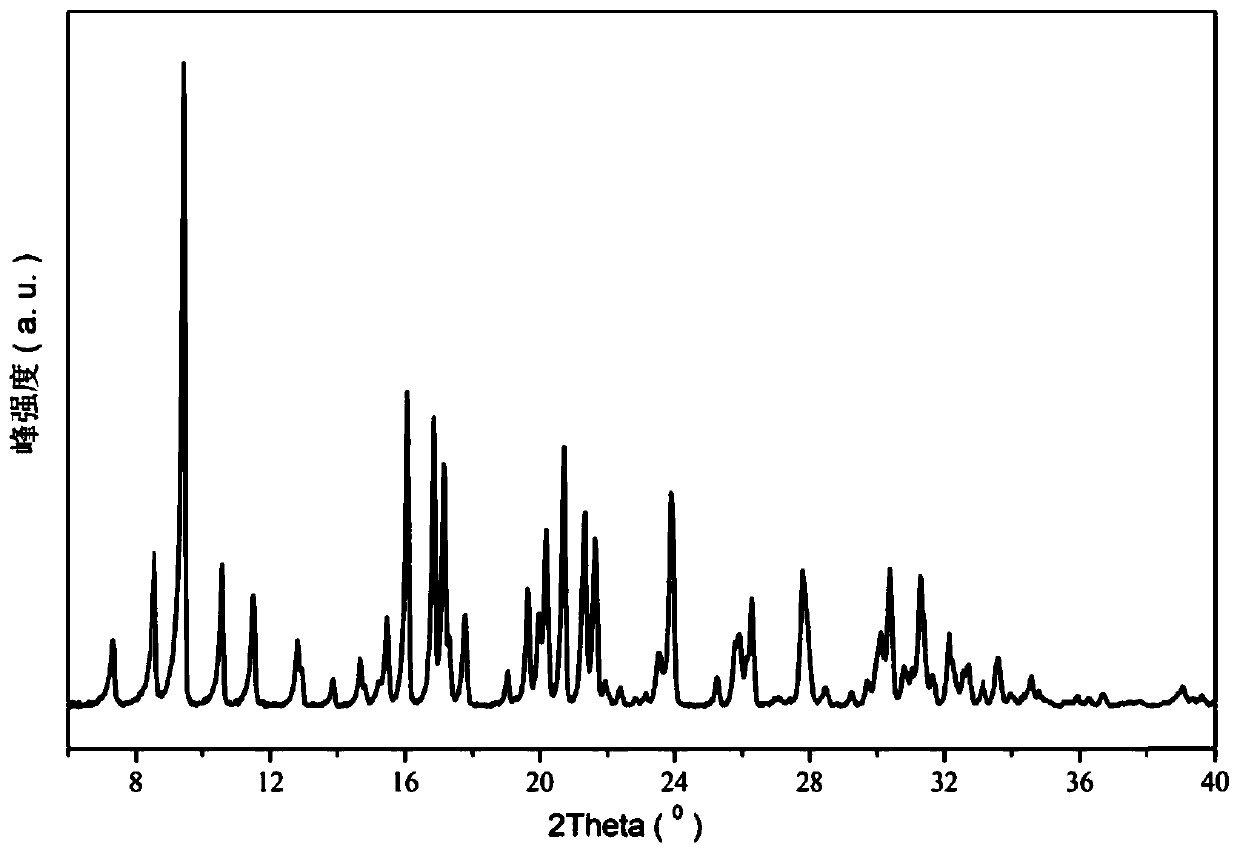

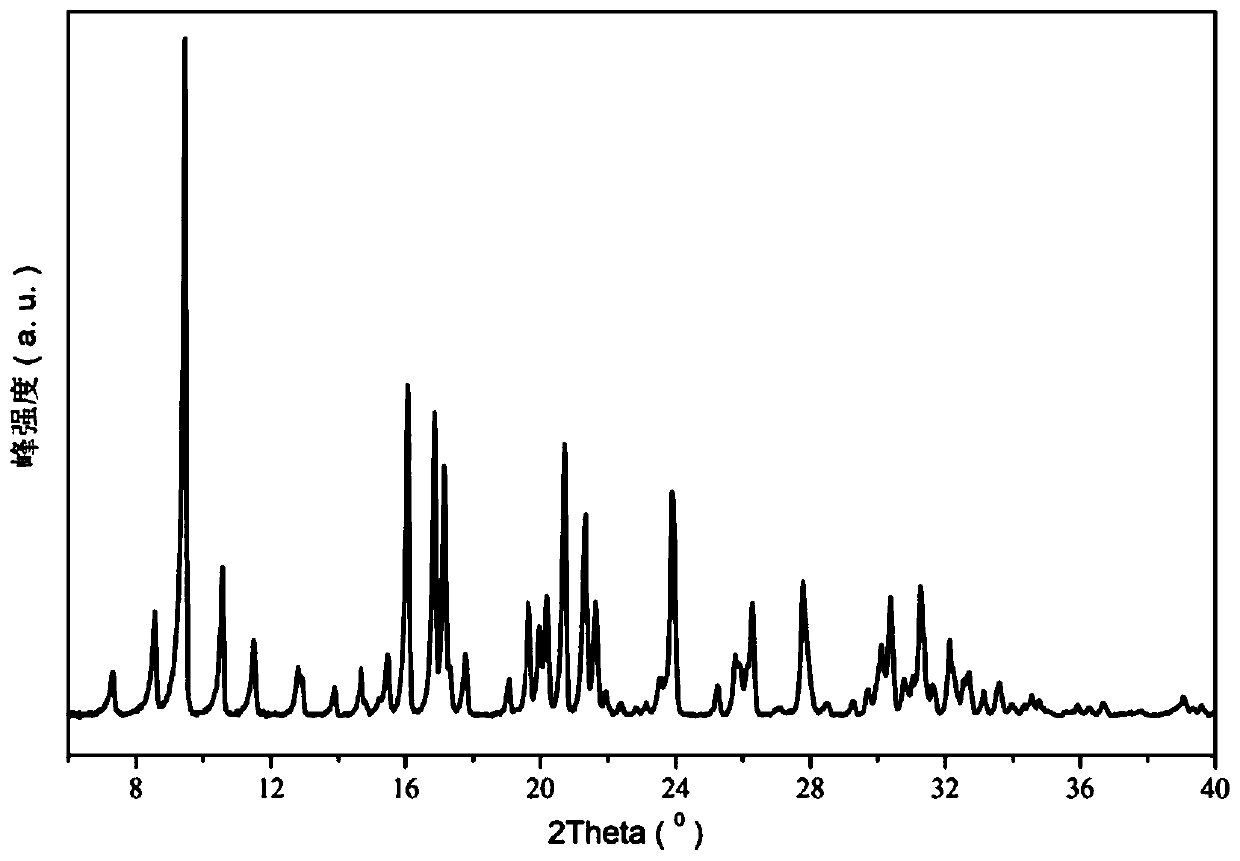

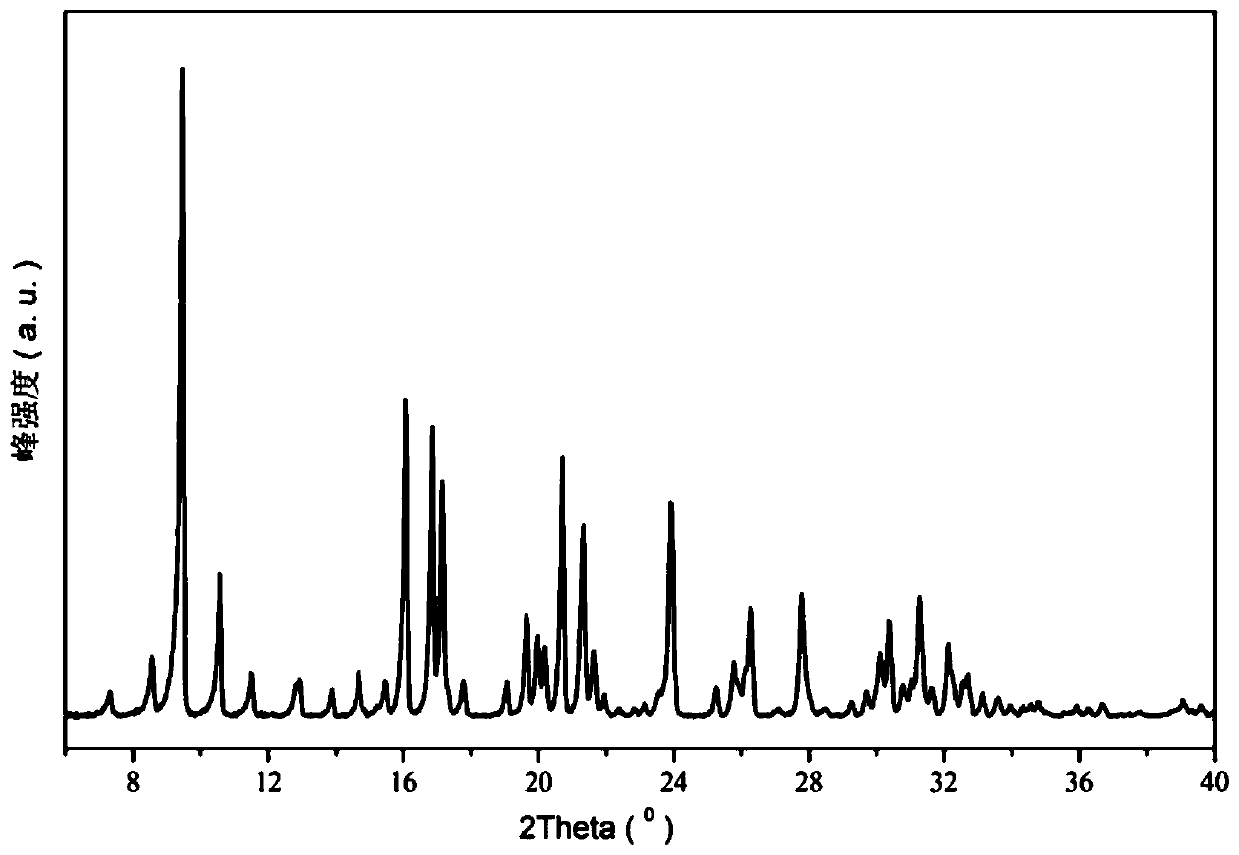

The invention discloses a CHA molecular sieve, a synthesis method thereof, and a denitration SCR catalyst synthesized by using the CHA molecular sieve. In the CHA molecular sieve, the molar ratio of silicon dioxide to aluminum oxide ranges from 5 to 75, the grain size ranges from 0.3 micrometer to 2 micrometers, after CHA molecular sieve raw powder is subjected to saturated steam treatment at thetemperature of 600 DEG C to 850 DEG C, tetra-coordinated aluminum accounts for more than or equal to 92 percent of the total aluminum amount, and the hexa-coordinate aluminum accounts for less than orequal to 8% of the total aluminum amount. The synthesis method comprises the step of synthesizing by using a composite organic template agent formed by a quaternary ammonium onium compound containingtetrahydronaphthalene or decahydronaphthalene groups and an N, N, N-dimethyl ethyl cyclohexyl quaternary ammonium onium compound. The molecular sieve disclosed by the invention has high hydrothermalstability under the condition of not having a large grain diameter, and the SCR catalyst disclosed by the invention also shows high nitrogen oxide reduction characteristics after being exposed at hightemperature and high humidity, and particularly shows high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

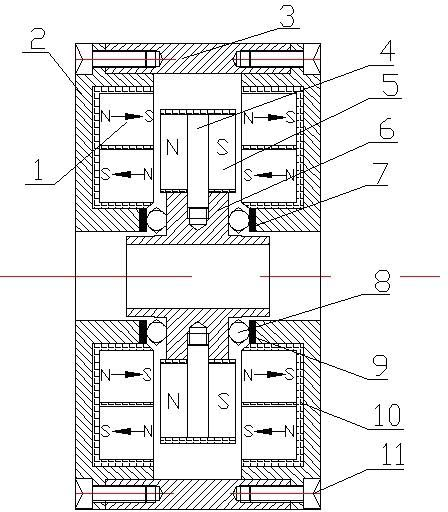

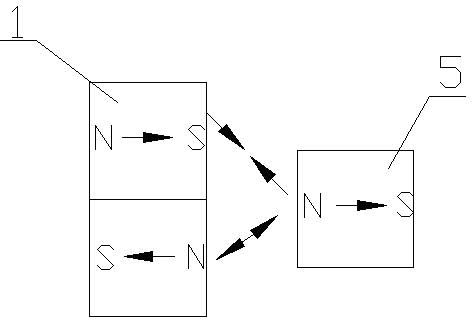

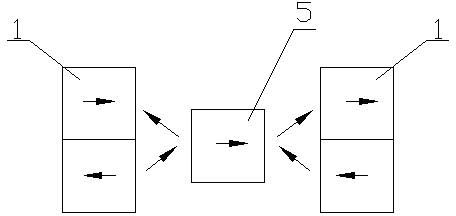

Preloaded radial permanent magnet bearing

InactiveCN102537047AImprove bearing capacityIncrease stiffnessBearingsMagnetic bearingMagnetic poles

The invention relates to a preloaded radial permanent magnet bearing which comprises side rings, an external ring, an internal ring, a magnetism conducting sheet, a ceramic ball component, a static permanent magnet ring set and a movable permanent magnet ring set; the static permanent magnet ring set consists of eight semi-circular permanent magnet rings respectively embedded in two side rings; and the movable permanent magnet ring set consists of an integrated permanent magnet ring and is positioned on the internal ring by set screws. The axial clearance between the static permanent magnet ring set and the movable permanent magnet ring set is constant and equal and is positioned by the ceramic ball component; the ceramic ball component consists of a housing washer and a ceramic ball; and the magnetism conducting sheet is made from a material with high magnetic conductivity. The preload of the bearing is realized by the permanent magnet rings with opposite magnetic pole directions, the bearing capacity of the permanent magnet bearing is greatly increased, the conventional mechanical bearing is replaced by a ceramic ball self-lubricating system with extremely small frictional force, and the bearing is simple and reliable in structure, convenient and fast to use, and convenient for serialized production.

Owner:SHANGHAI UNIV

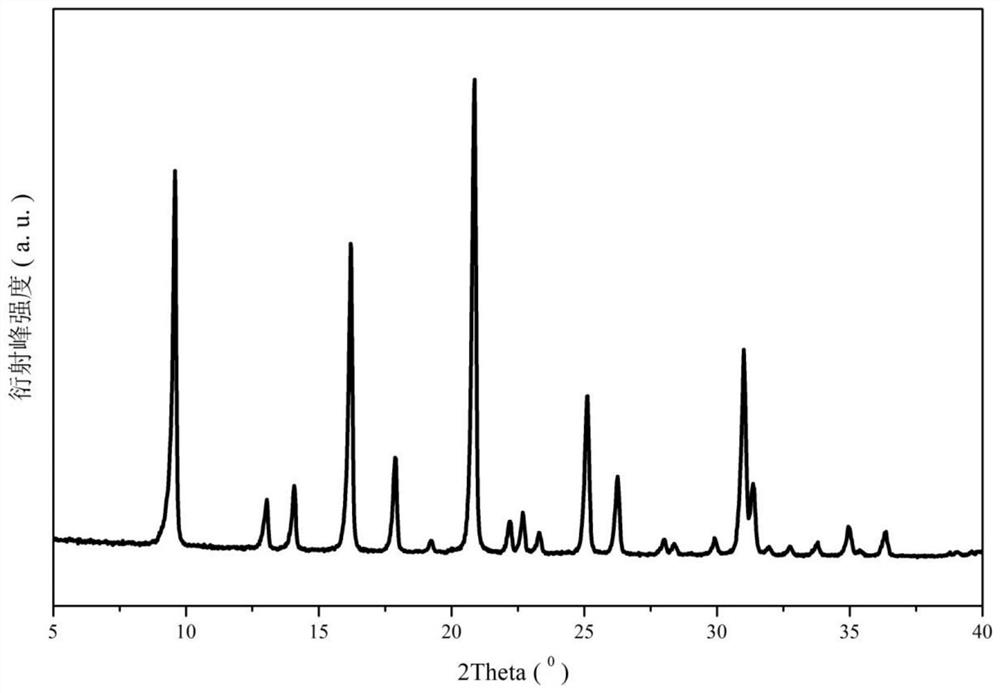

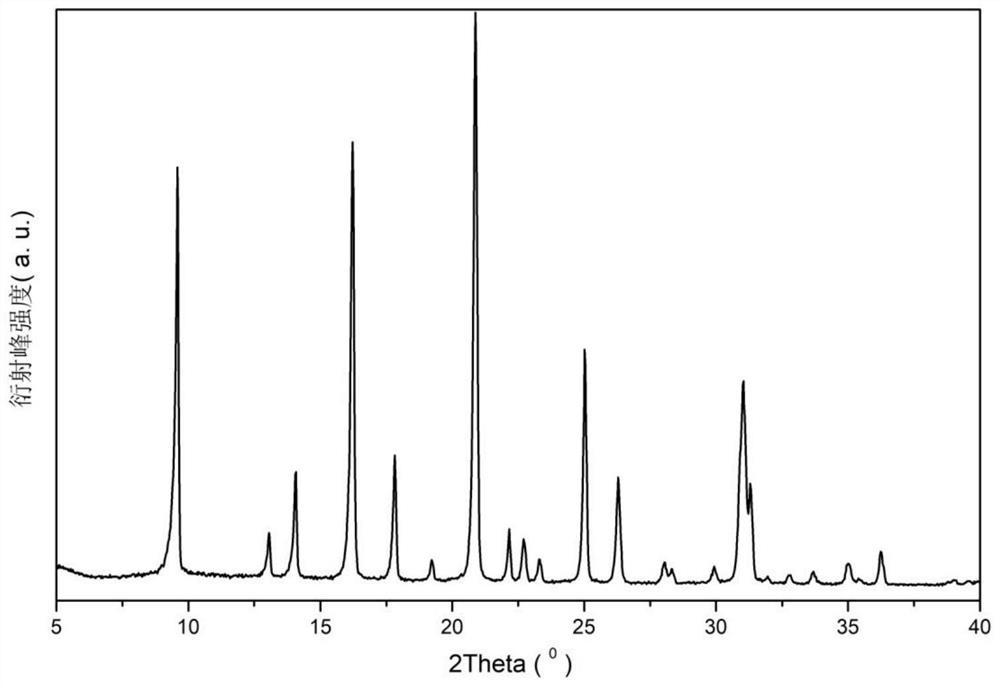

CHA type aluminum-silicon molecular sieve and preparation method and application of SCR catalyst

PendingCN111871455AReasonably acidicGood hydrothermal stabilityMolecular sieve catalystsInternal combustion piston enginesChemical synthesisMolecular sieve

The invention discloses a CHA type aluminum-silicon molecular sieve and a preparation method and application of an SCR catalyst, and belongs to the field of chemical synthesis technology and application thereof. The CHA type aluminosilicate zeolite molecular sieve is synthesized by adopting an N,N,N-trialkylbicyclo[2.2.2]octylammonium compound as an organic template agent, wherein the molar ratiorange of silicon dioxide to aluminum oxide in the product is 6-80, the average grain diameter is less than or equal to 500 nm, the total specific surface area is more than or equal to 400m2 / g, the total pore volume is more than or equal to 0.20 ml / g, the micropore volume is not less than 0.10 ml / g, and the grain diameter in the crystal face (-210) direction of the molecular sieve is 50-160 nm. After hydrothermal treatment of the molecular sieve at 600-800 DEG C, the tetra-coordinated aluminum accounts for more than or equal to 90% of the total aluminum amount, and the hexa-coordinated aluminumaccounts for less than or equal to 10% of the total aluminum amount. The molecular sieve provided by the invention has high hydrothermal stability without large crystal grains, shows high nitrogen oxide reduction characteristics, and especially shows a catalyst with high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

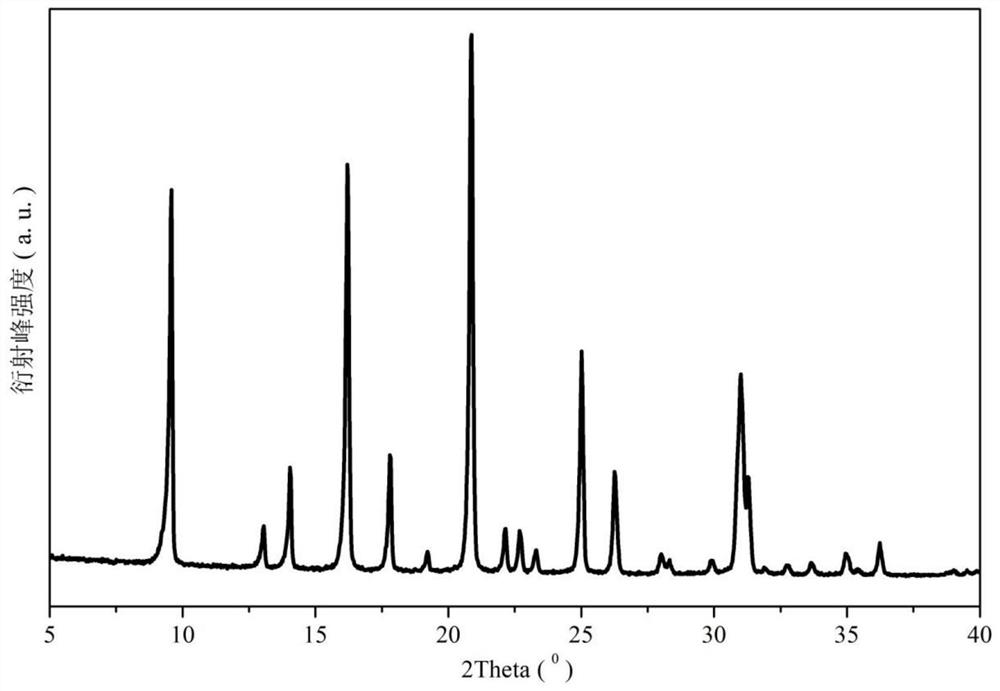

CHA type chabazite molecular sieve and synthesis method and application thereof

ActiveCN111960434AReasonably acidicGood hydrothermal stabilityMaterial nanotechnologyMolecular sieve catalystsMolecular sieveChemical synthesis

The invention discloses a CHA type chabazite molecular sieve and a synthesis method and application thereof, and belongs to the field of chemical synthesis technology and application thereof. The CHAtype chabazite molecular sieve is synthesized from N, N, N-trialkyl-N-phenyl quaternary ammonium salt or quaternary ammonium base compound as an organic template agent. The molar ratio of silicon dioxide to aluminum oxide of the CHA type chabazite molecular sieve ranges from 5 to 80, wherein the average grain diameter is less than or equal to 500 nm. The BET method determines that the total specific surface area is greater than or equal to 400 m <2> / g, the total pore volume is greater than or equal to 0.20 ml / g, the micropore pore volume is greater than or equal to 0.10 ml / g, and the grain diameter in the crystal face (-210) direction is 50-160 nm. The molecular sieve provided by the invention has high hydrothermal stability under the condition of no large crystal grains, and shows high nitrogen oxide reduction characteristics after being exposed at high temperature and high humidity, especially shows high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

CHA type molecular sieve synthesized by using quaternary ammonium onium template agent containing double cyclic groups, catalyst, preparation and application

PendingCN111960433AReasonably acidicGood hydrothermal stabilityGas treatmentInternal combustion piston enginesChemical synthesisMolecular sieve

The invention discloses a CHA type molecular sieve synthesized by using a quaternary ammonium onium template agent containing double cyclic groups, a catalyst, a preparation method and an applicationof the catalyst, and belongs to the field of chemical synthesis technologies and application thereof. The CHA type zeolite molecular sieve is synthesized by forming a composite organic template agentfrom a quaternary ammonium onium compound containing double cyclic groups and alkyl substituted quaternary ammonium base. The molar ratio range of the product silicon dioxide relative to aluminum oxide is 5-80, the average grain diameter is smaller than or equal to 500 nm, the total specific surface area is larger than or equal to 400 m <2> / g, the total pore volume is larger than or equal to 0.20ml / g, the micropore pore volume is larger than or equal to 0.10 ml / g, snd the grain diameter in the crystal face (-210) direction is 50-160nm. The molecular sieve provided by the invention has high hydrothermal stability under the condition of no large grain diameter, shows high nitrogen oxide reduction characteristics after high-temperature and high-humidity exposure, and especially shows high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

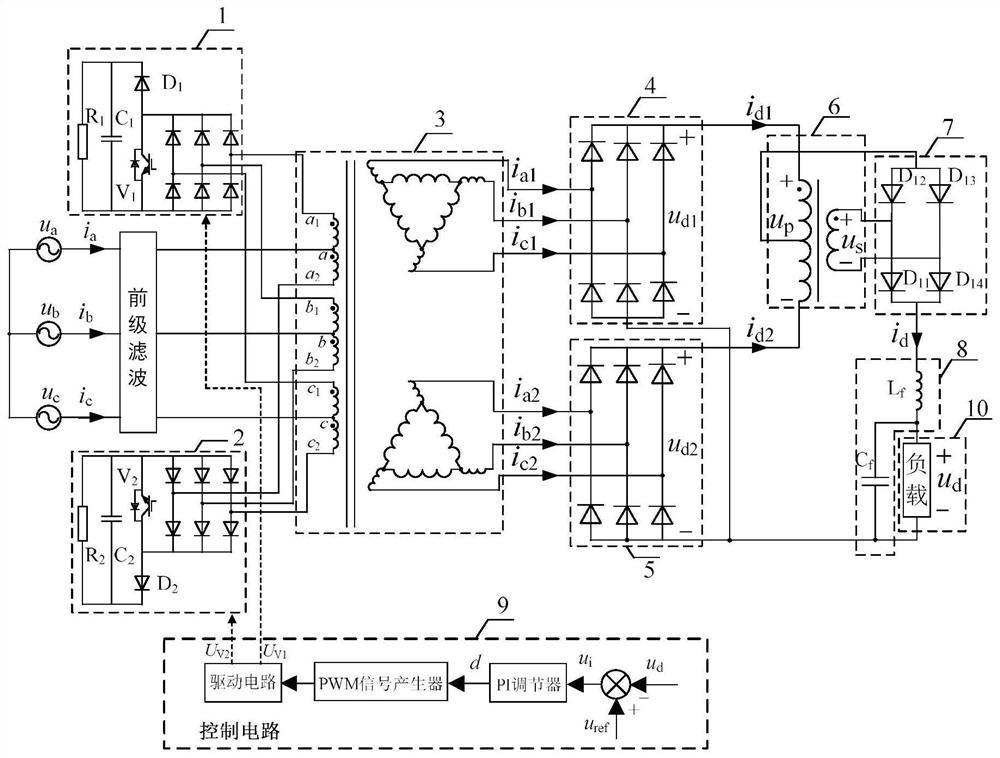

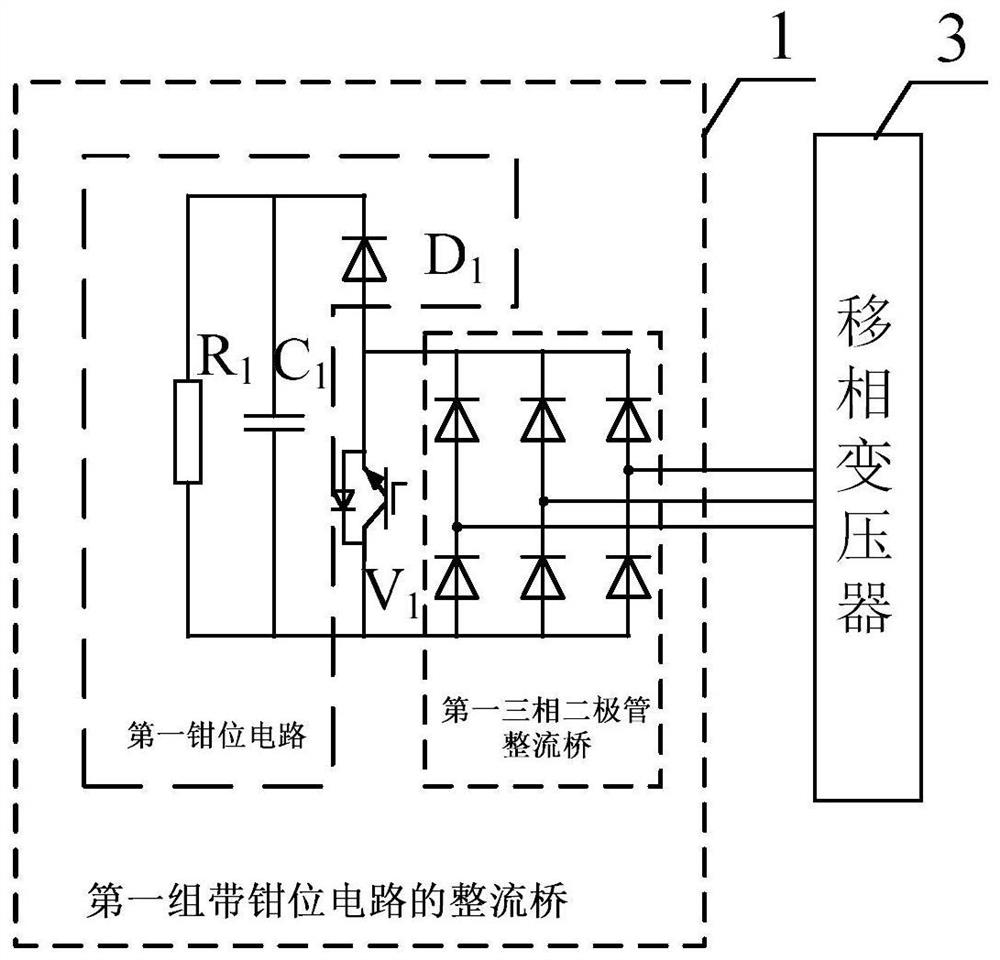

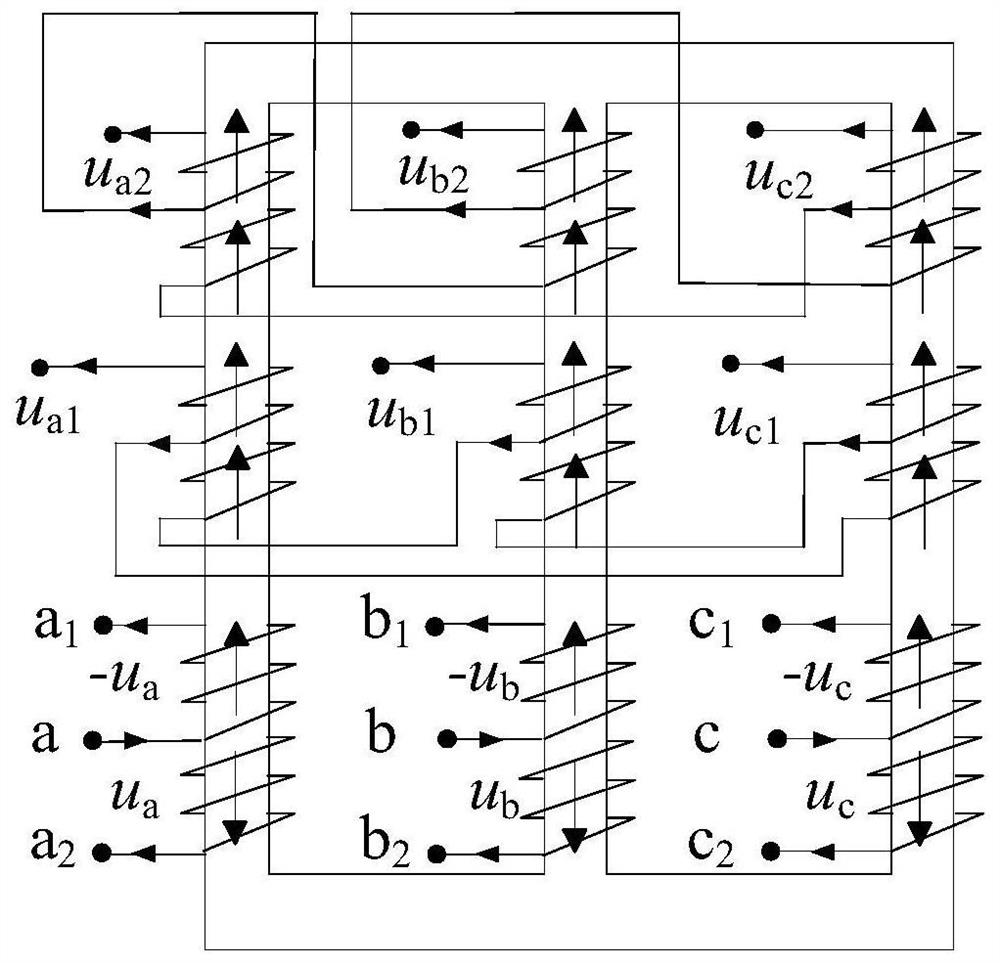

Simplified multi-pulse rectifier based on double-switch power electronic phase-shifting transformer

The invention discloses a simplified multi-pulse rectifier based on a double-switch power electronic phase-shifting transformer, and belongs to the technical field of power electronics. The simplifiedmulti-pulse rectifier solves the problem that an existing isolation type phase-shifting transformer is large in size / weight, meanwhile, the pulse number of the rectifier is multiplied in a simple mode, input current harmonic waves are effectively restrained, and continuous adjustment of the output voltage of the rectifier is achieved. The simplified multi-pulse rectifier comprises a first group of rectifier bridges with clamping circuits, a second group of rectifier bridges with clamping circuits, a phase-shifting transformer, a first group of three-phase rectifier bridges, a second group ofthree-phase rectifier bridges, a balance reactor with a secondary winding, a single-phase rectification circuit, a post-stage filter circuit and a control circuit, wherein a turn ratio of a primary side winding to the secondary side winding of the balance reactor with the secondary side winding is 0.246, and at the moment, the balance reactor with the secondary side winding and the single-phase rectification circuit form a pulse multiplication balance reactor which is used for realizing the pulse number multiplication of the rectifier. The simplified multi-pulse rectifier is mainly used for converting three-phase alternating current into direct current.

Owner:HARBIN ENG UNIV

CHA structure molecular sieve as well as preparation method and application of tail gas denitration catalyst of the CHA structure molecular sieve

PendingCN111871450AReasonably acidicGood hydrothermal stabilityMolecular sieve catalystsInternal combustion piston enginesChemistryMolecular sieve

The invention discloses a CHA structure molecular sieve and a preparation method and application of a tail gas denitration catalyst of the CHA structure molecular sieve, and belongs to the field of chemical synthesis technology and application thereof. An N,N,N-trialkyl-(norcamphane-2-yl)-quaternary ammonium onium compound is used as an organic template agent to synthesize the CHA structure molecular sieve, the molar ratio of silicon dioxide to aluminum oxide ranges from 6 to 80, the average grain diameter is smaller than or equal to 500 nm, the total specific surface area is larger than or equal to 400 m2 / g, the total pore volume is larger than or equal to 0.20 ml / g, the micropore volume is larger than or equal to 0.10 ml / g, and the grain diameter size in the crystal face (-210) directionis 50-160 nm. After the molecular sieve is subjected to hydro-thermal treatment at 600-850 DEG C, the tetra-coordinated aluminum accounts for more than or equal to 90% of the total aluminum amount, and the hexa-coordinated aluminum accounts for less than or equal to 10% of the total aluminum amount. The molecular sieve provided by the invention has high hydrothermal stability without large crystal grains, shows high nitrogen oxide reduction characteristics after being exposed at high temperature and high humidity, and especially shows high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

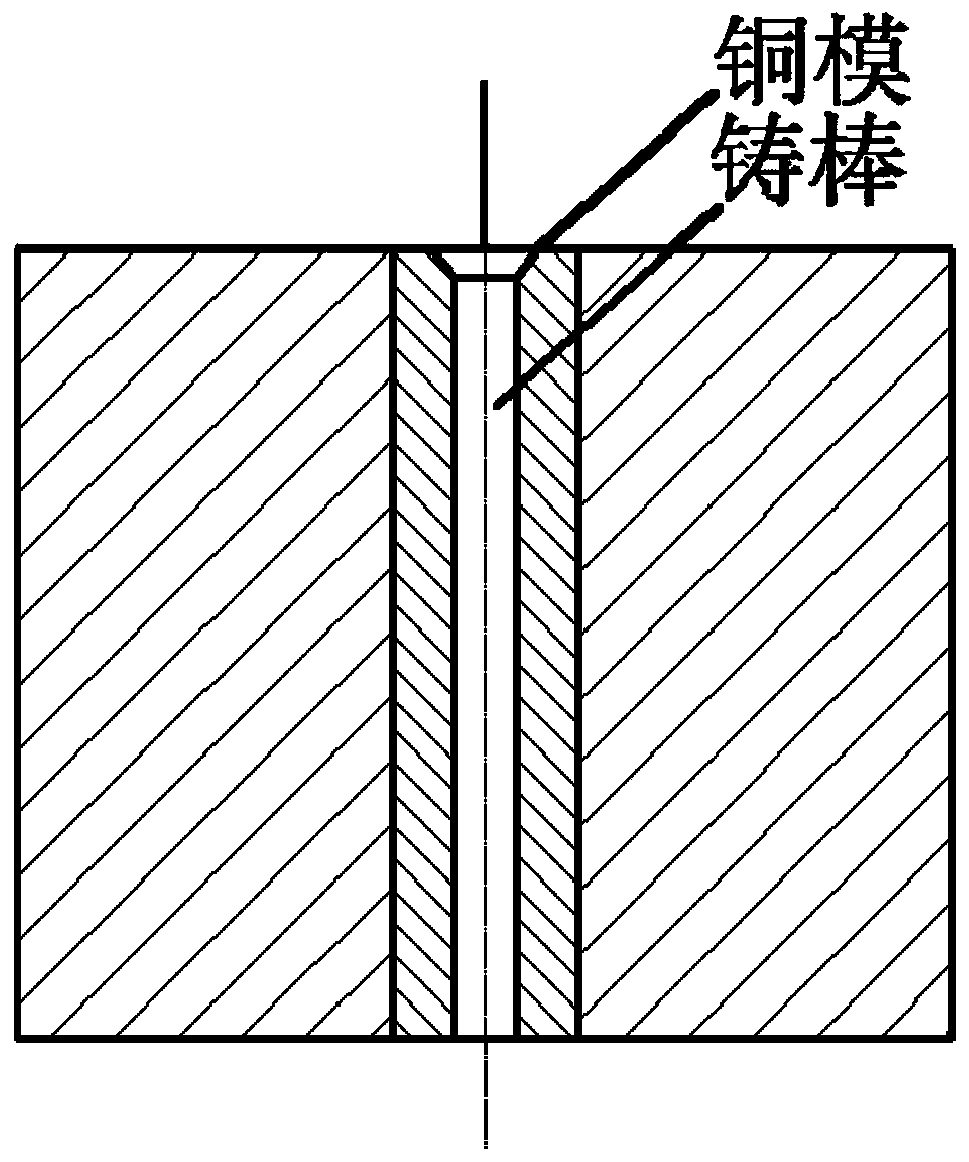

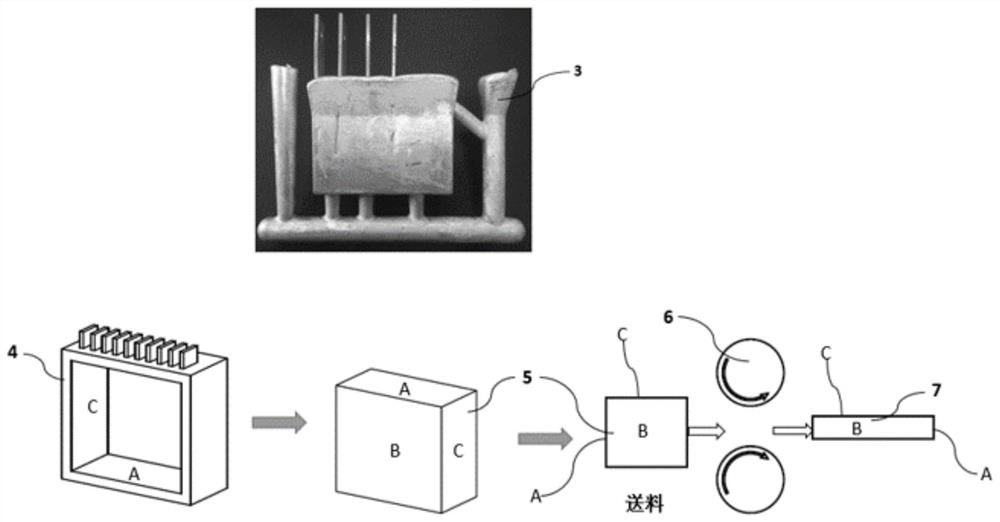

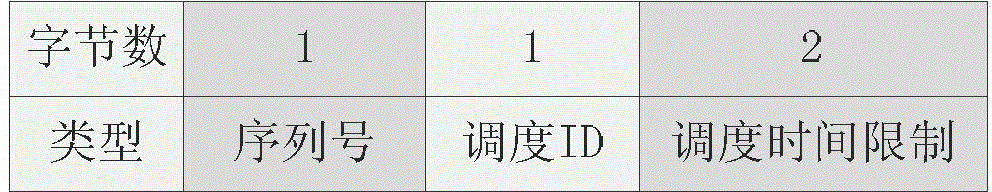

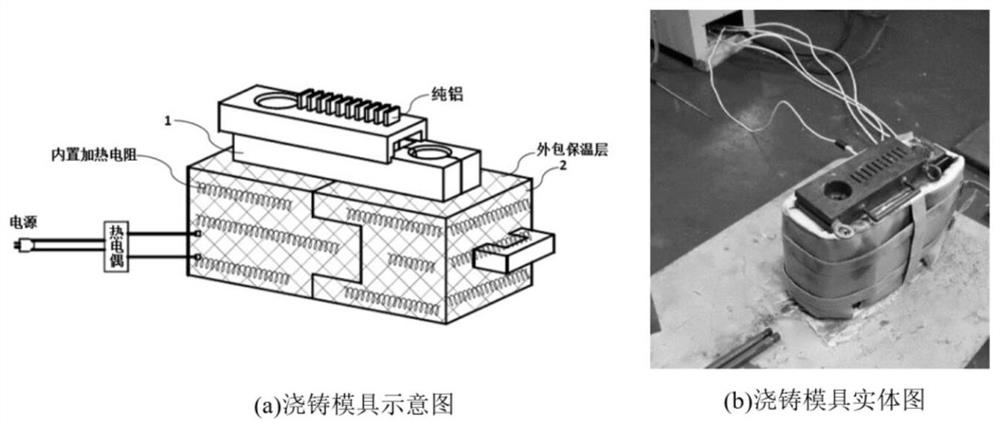

Preparation method of multi-grain-scale lamellar structure aluminum alloy

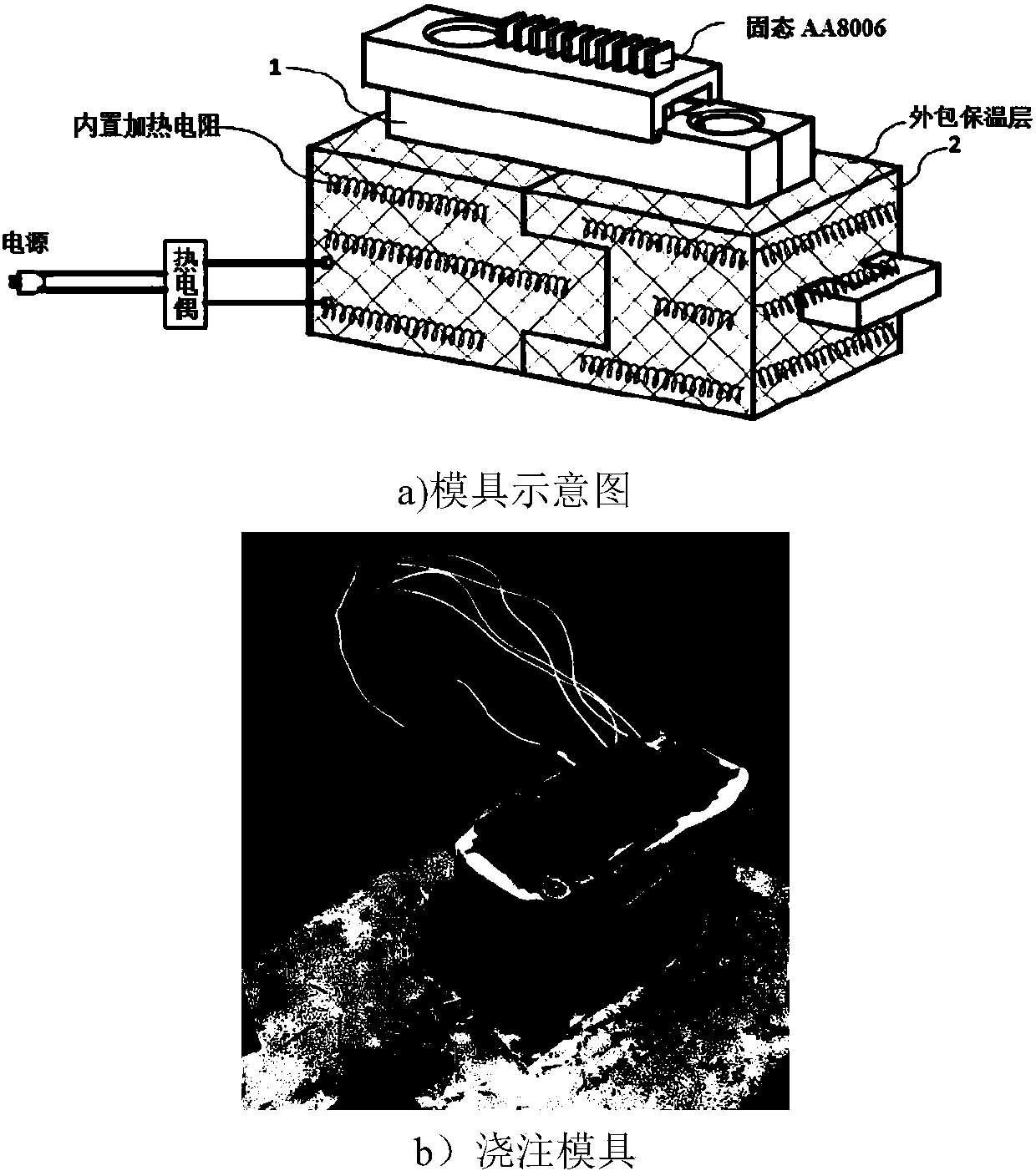

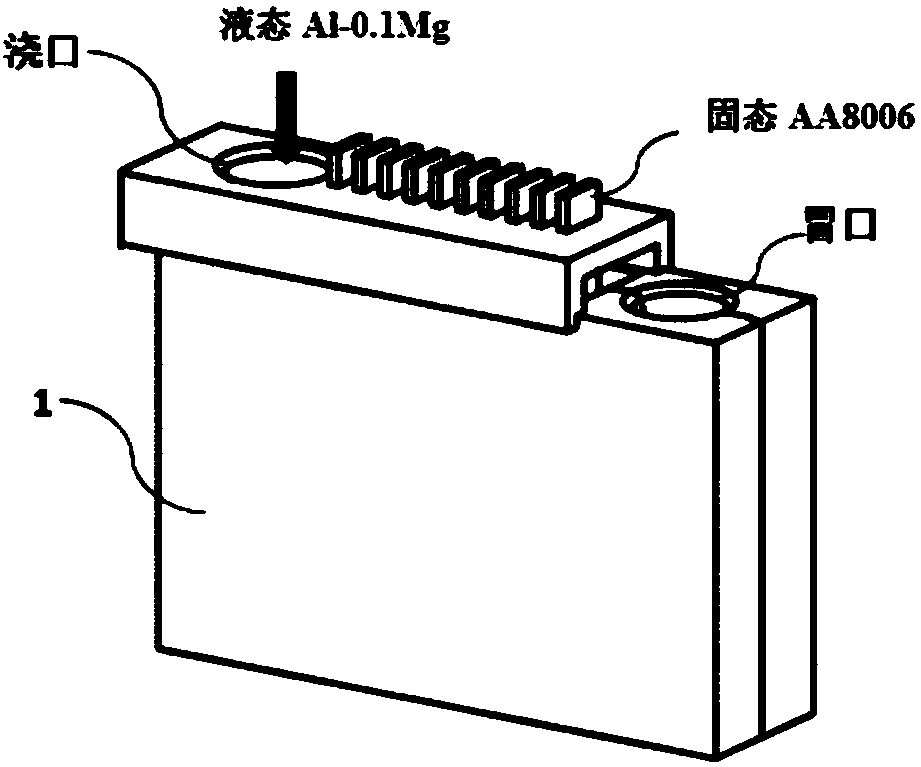

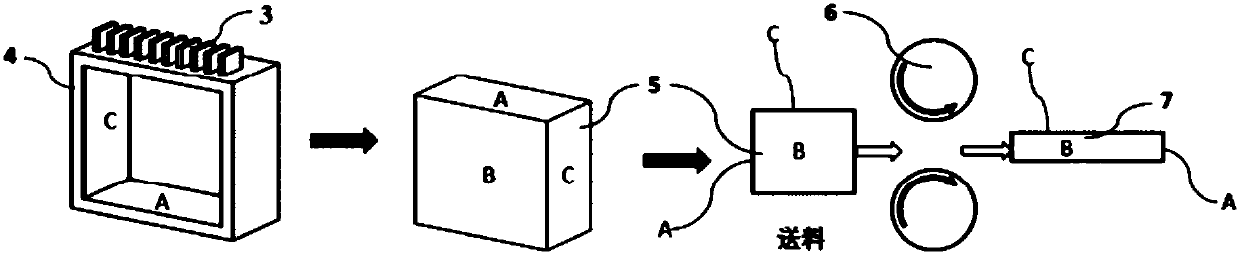

InactiveCN110343909AImprove performanceLarge structureGearingCylindersMaterials scienceLamellar structure

The invention discloses a preparation method of a multi-grain-scale lamellar structure aluminum alloy. The preparation method comprises the steps of pretreatment, casting, plastic deformation, multi-grain scale formation and the like, two or more kinds of aluminum alloys with different alloy components are selected, solid-liquid embedding casting is carried out, and the multi-layer composite aluminum alloy is formed. Plastic deformation and subsequent annealing treatment are performed to form phases with different grain sizes between adjacent layers to obtain the multi-grain-scale reinforced lamellar structure aluminum alloy material.

Owner:NANJING UNIV OF SCI & TECH

CHA molecular sieve synthesized by novel structure template agent and SCR catalyst and application thereof

PendingCN111871451AReasonably acidicGood hydrothermal stabilityMolecular sieve catalystsInternal combustion piston enginesMolecular sieveNitrogen oxides

The invention discloses a CHA molecular sieve synthesized by a novel structure template agent and an SCR catalyst and application thereof, and belongs to the field of chemical synthesis technology andapplication thereof. The CHA molecular sieve is synthesized by adopting one or more of N,N,N-trialkyl-(indan-5-yl)quaternary ammonium onium, N,N,N-trialkyl-(indan-1-yl)quaternary ammonium onium or N,N,N-trialkyl-(indan-4-yl)quaternary ammonium onium compounds as an organic template agent, wherein the molar ratio range of silicon dioxide to aluminum oxide is 6-80, the average grain diameter is less than or equal to 500nm, the total specific surface area is greater than or equal to 400m2 / g, the total pore volume is greater than or equal to 0.20 ml / g. the micropore volume is greater than or equal to 0.10 ml / g, and the grain diameter size in the crystal face (210) direction is 50-160 nm. The molecular sieve provided by the invention has high hydrothermal stability under the condition of no large crystal grains, also shows high nitrogen oxide reduction characteristics after high-temperature and high-humidity exposure, and especially shows a catalyst with high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

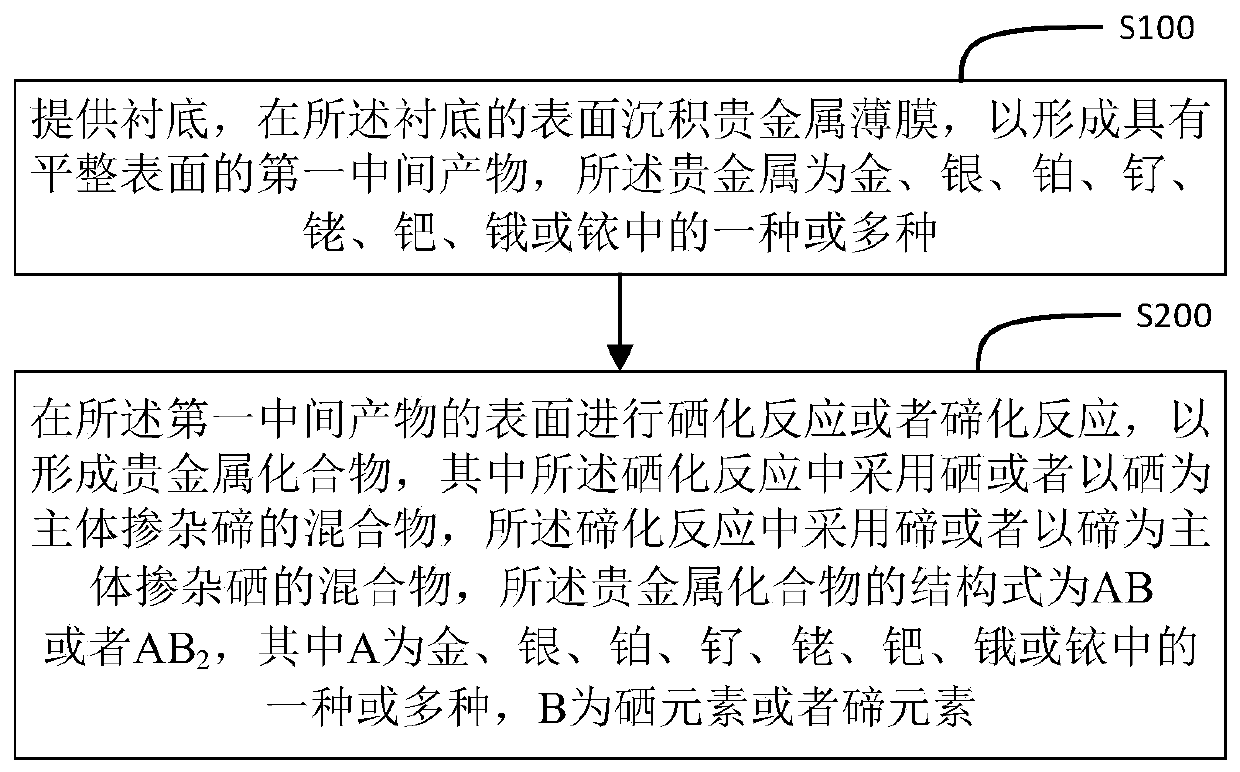

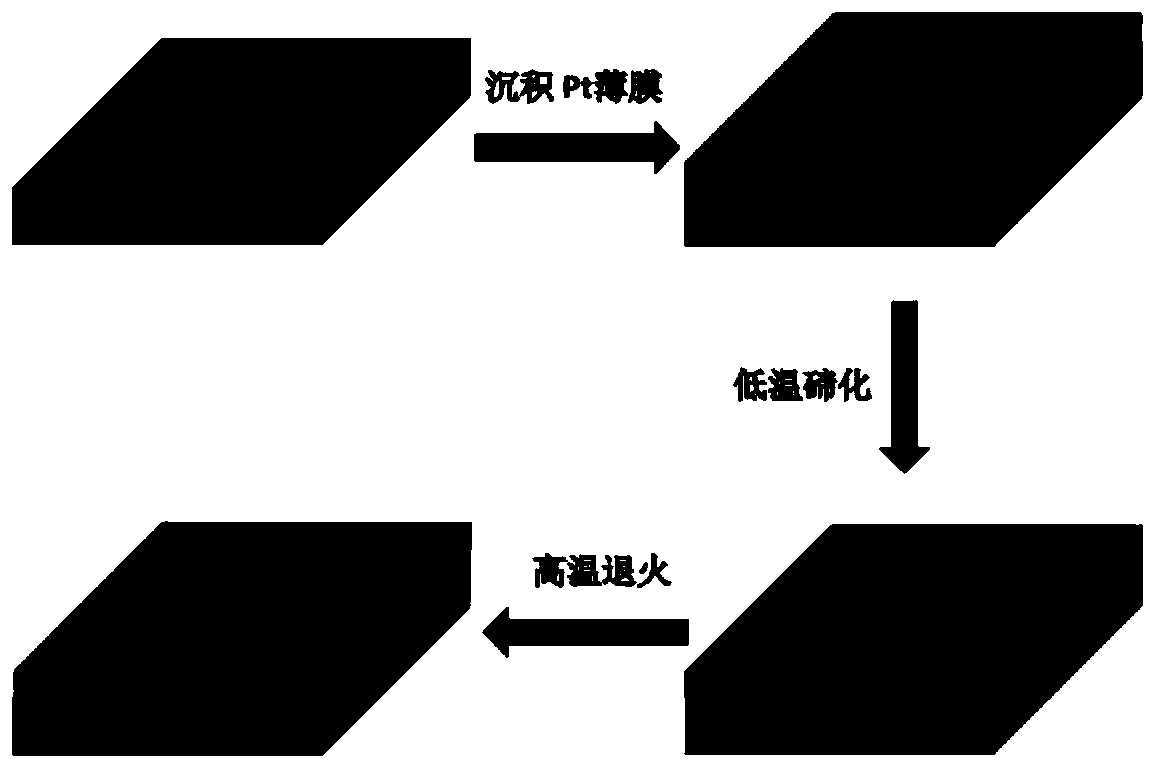

Preparation method of precious metal compound and application thereof

InactiveCN109904059AMeeting the needs of industrial applicationsPhysical/chemical process catalystsSemiconductor/solid-state device manufacturingIridiumPlatinum

The application relates to the field of materials science, and in particular to a preparation method of a precious metal compound and an application thereof. The preparation method of the precious metal compound includes the following steps of: providing a substrate, and depositing a precious metal film on the surface of the substrate to form a first intermediate product with a flat surface; and performing a selenization reaction or a tellurization reaction on the surface of the first intermediate product to form a precious metal compound. The structural formula of the precious metal compoundis AB or AB2, wherein A is one or more of gold, silver, platinum, ruthenium, rhodium, palladium, osmium or iridium, and B is a selenium element or a tellurium element. The precious metal compound prepared by the method can break away from the limitations of substrate materials in the preparation of the precious metal compound in the prior art. That is, the method can prepare the precious metal compound on any substrate material. In addition, the method can produce a large-sized precious metal compound, and the size of the precious metal compound can meet the needs of industrial applications.

Owner:TSINGHUA UNIV

CHA type molecular sieve for purifying diesel vehicle tail gas, catalyst, preparation method and application

InactiveCN111871452AReasonably acidicGood hydrothermal stabilityMolecular sieve catalystsDispersed particle separationChemical synthesisPtru catalyst

The invention discloses a CHA type molecular sieve for purifying diesel vehicle tail gas, a catalyst, a preparation method and application, and belongs to the field of chemical synthesis technology and application thereof. The CHA-type aluminosilicate zeolite molecular sieve is synthesized by adopting an N,N,N-trimethyl-3,3,5-trimethylcyclohexyl quaternary ammonium onium compound as an organic template agent, wherein the molar ratio of silicon dioxide to aluminum oxide is 6-80, the average grain diameter is less than or equal to 500nm, the total specific surface area is more than or equal to 400m2 / g, the total pore volume is more than or equal to 0.20 ml / g, the micropore volume is more than 0.10 ml / g, and thecrystal grain diameter in the crystal face (-210) direction is 50-160 nm. After the molecular sieve is subjected to hydro-thermal treatment at 600-850 DEG C, the tetra-coordinated aluminum accounts for more than or equal to 90% of the total aluminum amount, and the hexa-coordinatedaluminum accounts for less than or equal to 10% of the total aluminum amount. The molecular sieve provided by the invention has high hydrothermal stability under the condition of no large crystal grains, and shows high nitrogen oxide reduction characteristics after being exposed at high temperature and high humidity, especially shows high nitrogen oxide reduction characteristics in a temperaturerange of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

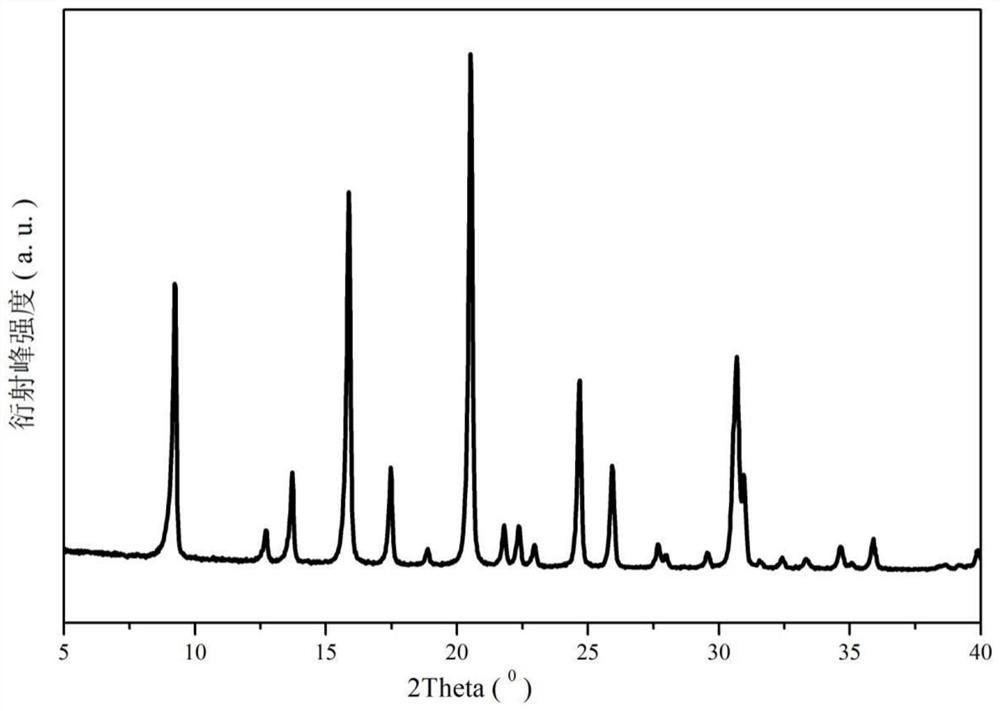

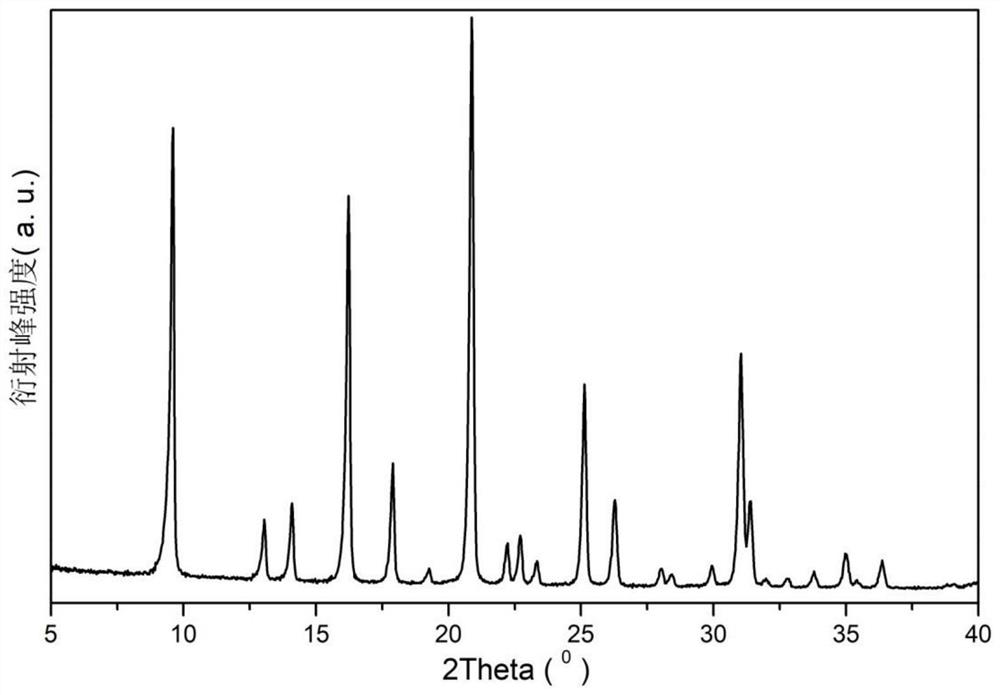

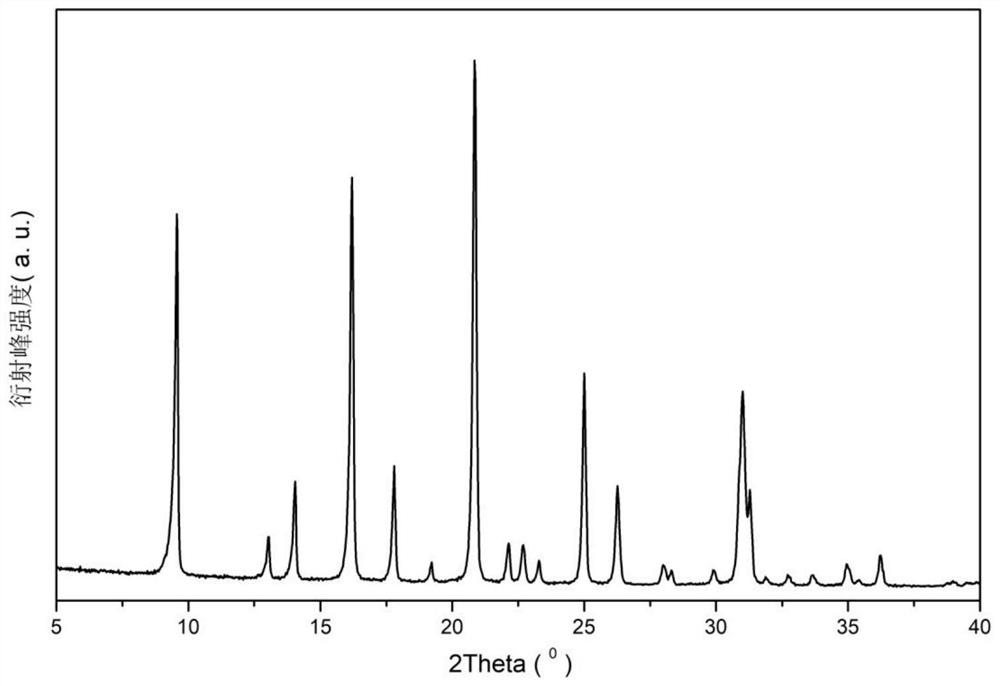

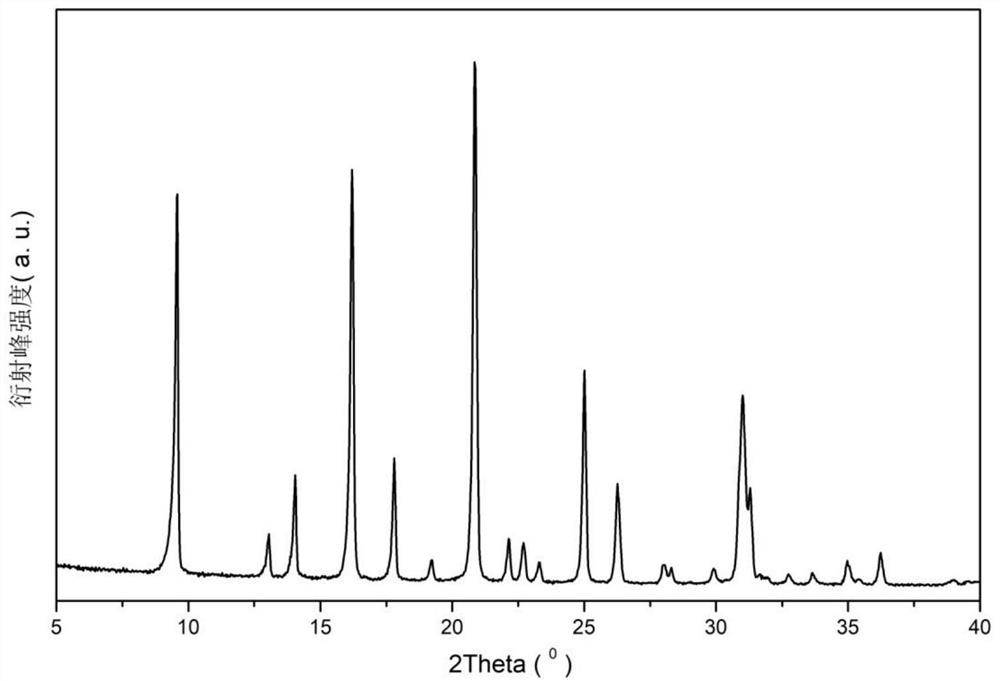

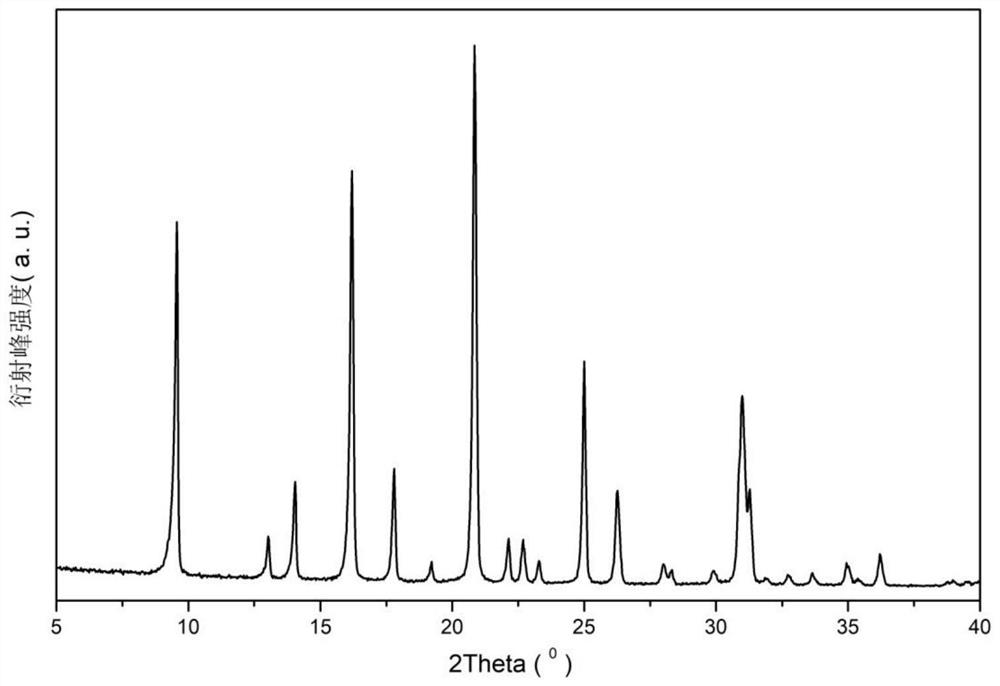

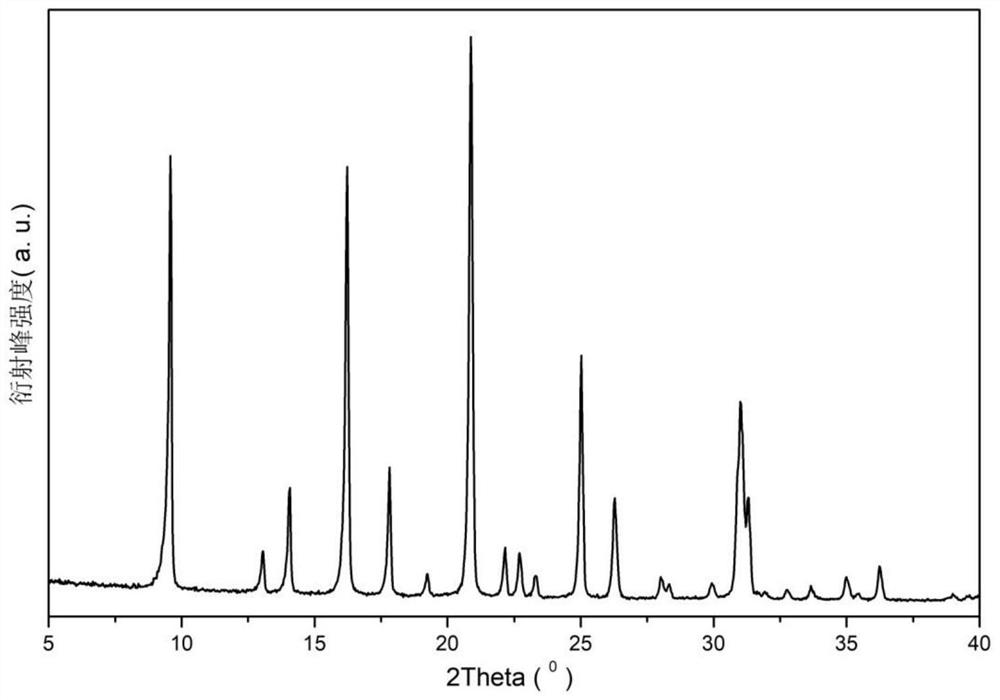

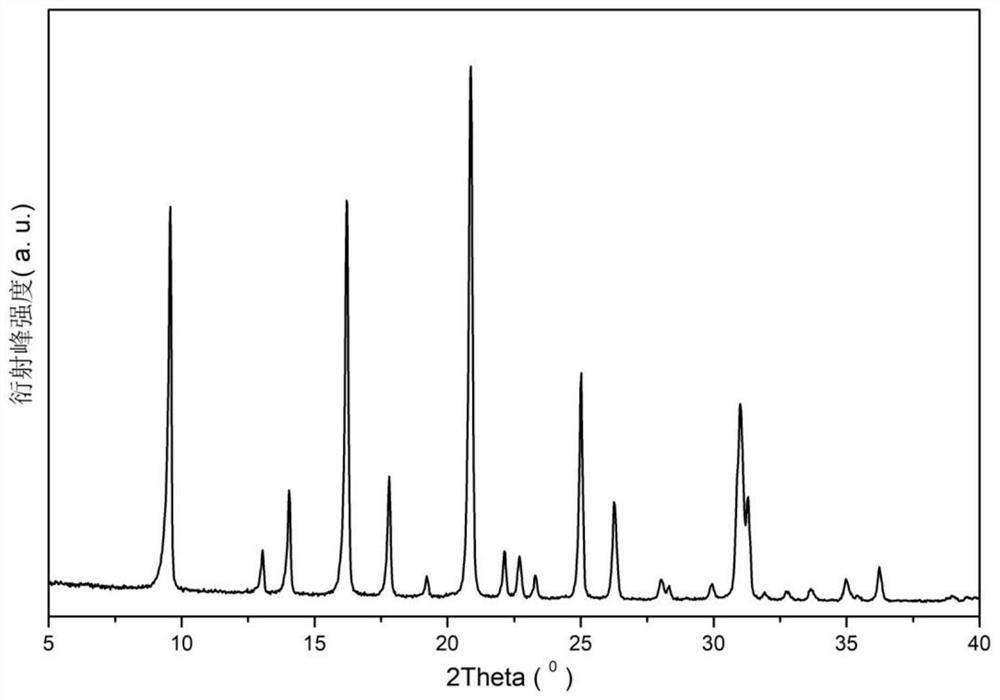

AEI/AFX structure symbiotic composite molecular sieve as well as preparation method and SCR application thereof

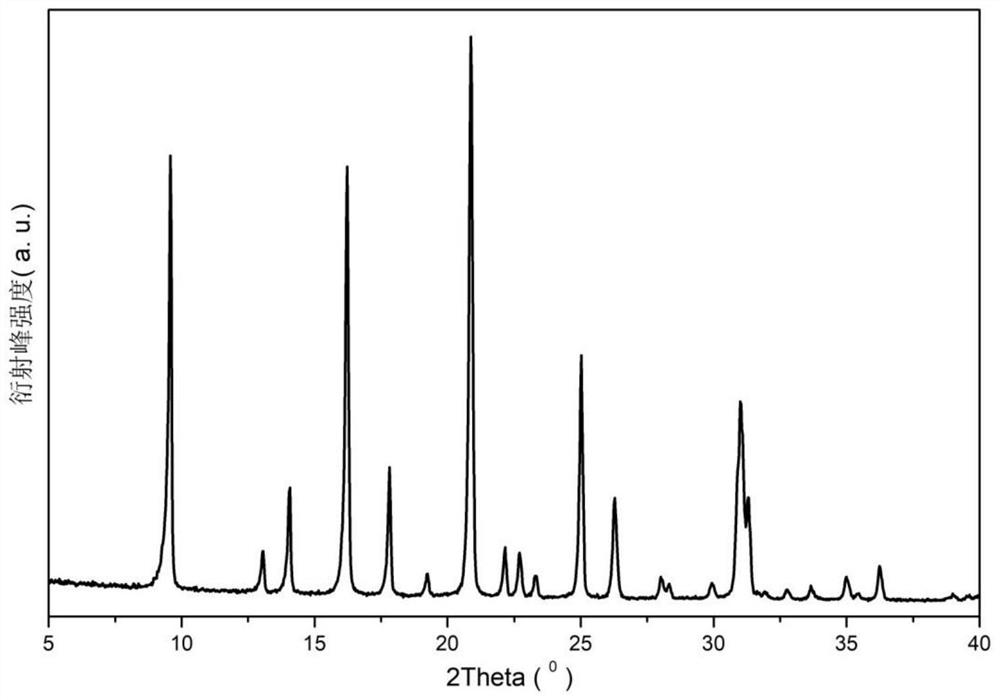

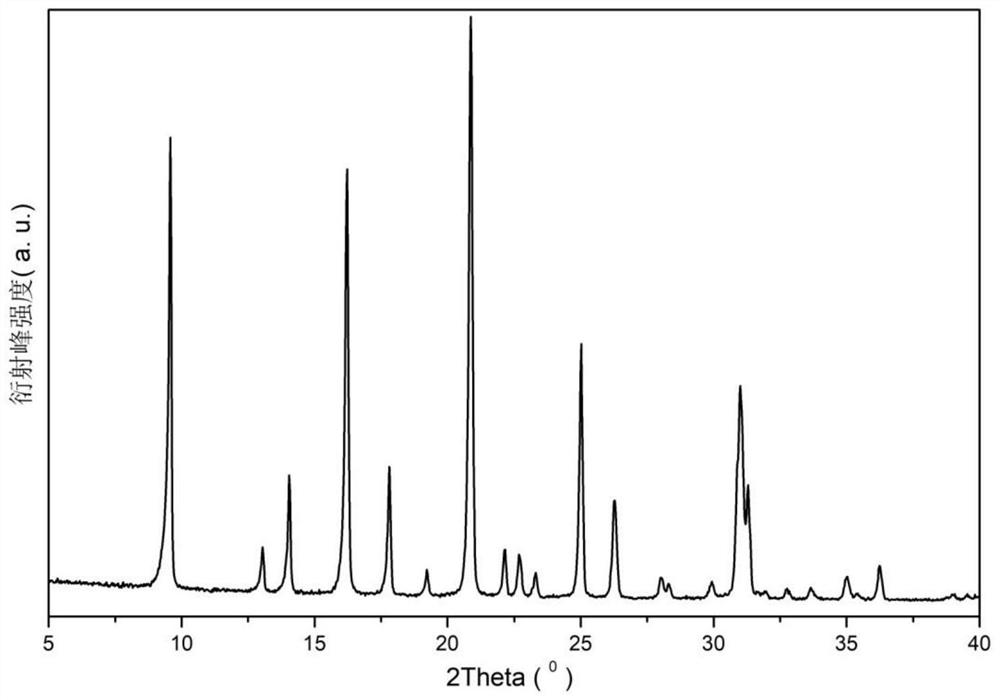

InactiveCN111001437AReasonably acidicReasonable distribution of acidityMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

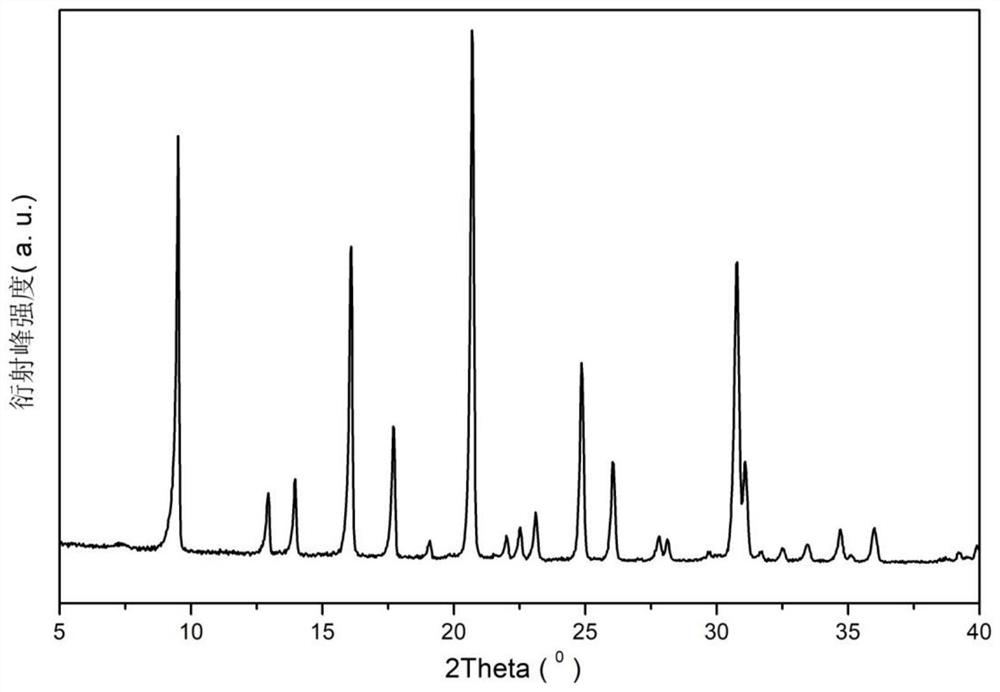

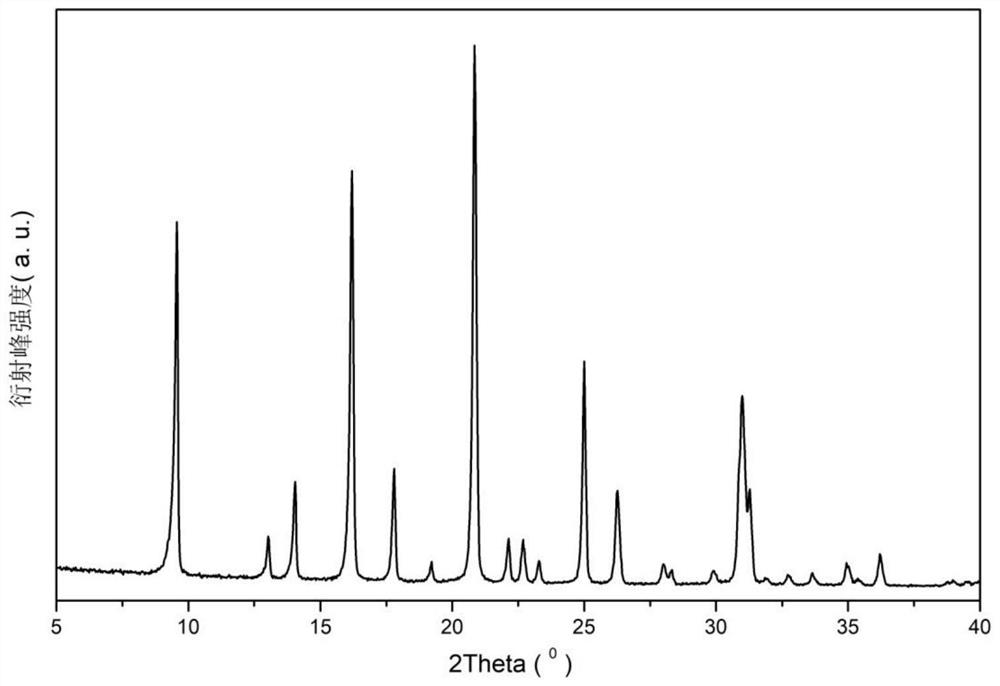

The invention discloses an AEI / AFX topological structure symbiotic composite molecular sieve and a preparation method of an SCR catalyst, the AEI / AFX topological structure symbiotic composite molecular sieve is formed by symbiosis of AEI and AFX topological structure molecular sieves, and a characteristic diffraction peak exists at a 2 theta angle in an X-ray diffraction phase spectrogram of the molecular sieve with a symbiotic composite structure; wherein the molar ratio of silicon to aluminum oxide in the symbiotic composite molecular sieve is 10-200. In the preparation process of the symbiotic composite molecular sieve, a composite template agent is adopted; an FAU type silicon-aluminum molecular sieve is used as an aluminum source and a silicon source, other silicon sources and alkalisources can be combined to form mixed sol, an AEI / AFX symbiotic structure molecular sieve is synthesized through dynamic crystallization according to temperature sections, and then the AEI / AFX symbiotic structure molecular sieve exchanges with soluble metal salt cations to obtain the SCR molecular sieve catalyst. The SSZ-39 with the AEI structure and the SSZ-16 with the AFX structure form the symbiotic composite molecular sieve; the composite molecular sieve has more reasonably distributed acidity and good hydrothermal stability, has good catalytic activity and excellent service life in SCR reaction of NOx-containing gas discharged by a moving source and a fixed source, and can well meet the standard requirements of tail gas emission.

Owner:CHINA CATALYST HLDG CO LTD

Nitrogen oxide purification CHA zeolite molecular sieve as well as preparation method and application of catalyst thereof

PendingCN111871454AReasonably acidicGood hydrothermal stabilityInternal combustion piston enginesMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a nitrogen oxide purification CHA zeolite molecular sieve as well as a preparation method and application of a catalyst thereof, and belongs to the field of chemical synthesistechnologies and application thereof. The CHA zeolite molecular sieve is synthesized by adopting an N,N,N-trialkyl-quinuclidine-4-quaternary ammonium onium compound as an organic template agent, the molar ratio range of silicon dioxide to aluminum oxide is 6-80, the average grain diameter is less than or equal to 500 nm, the total specific surface area is more than or equal to 400m2 / g, the total pore volume is more than or equal to 0.20 ml / g, the micropore volume is more than or equal to 0.10 ml / g, and the grain diameter in the crystal face (-210) direction of the molecular sieve is 50-160 nm.After hydrothermal treatment of the molecular sieve at 600-800 DEG C, the tetra-coordinated aluminum accounts for more than or equal to 90% of the total aluminum amount, and the hexa-coordinated aluminum accounts for less than or equal to 10% of the total aluminum amount. The molecular sieve provided by the invention has high hydrothermal stability without large crystal grains, shows high nitrogen oxide reduction characteristics after being exposed at high temperature and high humidity, and especially shows a catalyst with high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

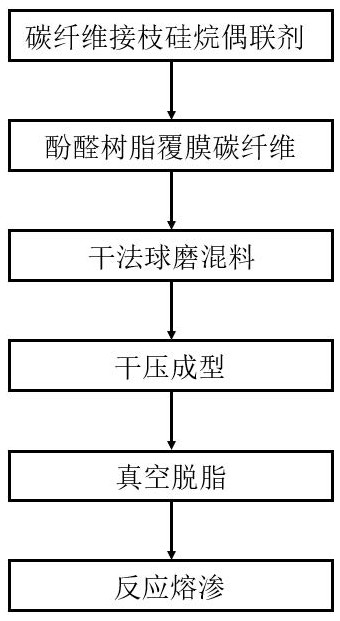

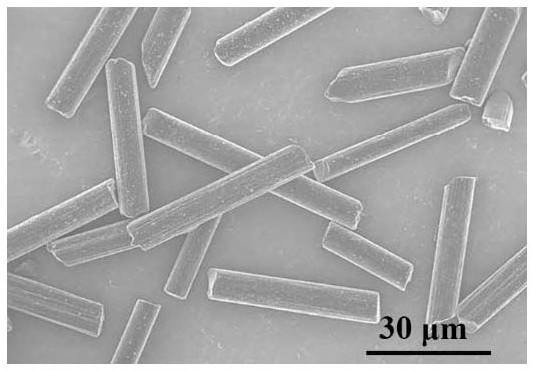

Chopped carbon fiber toughened silicon carbide composite material and preparation method thereof

The invention relates to a chopped carbon fiber toughened silicon carbide composite material and a preparation method thereof. The preparation method comprises the following steps of: reacting chopped carbon fibers with a silane coupling agent, absolute ethyl alcohol and deionized water to obtain coupling agent grafted chopped carbon fibers; mixing the coupling agent grafted chopped carbon fibers with an organic solution of a high-carbon-residual-rate binder to obtain high-carbon-residual-rate binder coated chopped carbon fibers; mixing the high-carbon-residual-rate binder coated chopped carbon fibers with silicon carbide powder to obtain mixed powder; performing dry pressing on the mixed powder to obtain a biscuit, and performing degreasing treatment to obtain a preform; and carrying out reactive infiltration on the preform to obtain the chopped carbon fiber toughened silicon carbide composite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

CHA structure molecular sieve, synthesis method, nitrogen oxide selective reduction catalyst and application

PendingCN111871453AReasonably acidicGood hydrothermal stabilityMolecular sieve catalystsInternal combustion piston enginesPtru catalystEngineering

The invention discloses a CHA structure molecular sieve and a synthesis method thereof, and a nitrogen oxide selective reduction catalyst and application thereof, and belongs to the field of chemicalsynthesis technology and application thereof. An N,N,N-trialkyl-(naphthyl-1-yl)quaternary ammonium onium compound is adopted as an organic template agent to synthesize the CHA structure molecular sieve, the molar ratio range of silicon dioxide to aluminum oxide is 6-80, the average grain diameter is smaller than or equal to 500 nm, the total specific surface area is larger than or equal to 400 m2 / g, the total pore volume is larger than or equal to 0.20 ml / g, the micropore volume is larger than or equal to 0.10 ml / g, and the grain diameter in the crystal face (-210) direction of the molecular sieve is 50-160 nm. The molecular sieve provided by the invention has high hydrothermal stability under the condition of no large crystal grains, and shows high nitrogen oxide reduction characteristicsafter being exposed at high temperature and high humidity, especially shows high nitrogen oxide reduction characteristics in a temperature range of 200-550 DEG C.

Owner:CHINA CATALYST HLDG CO LTD

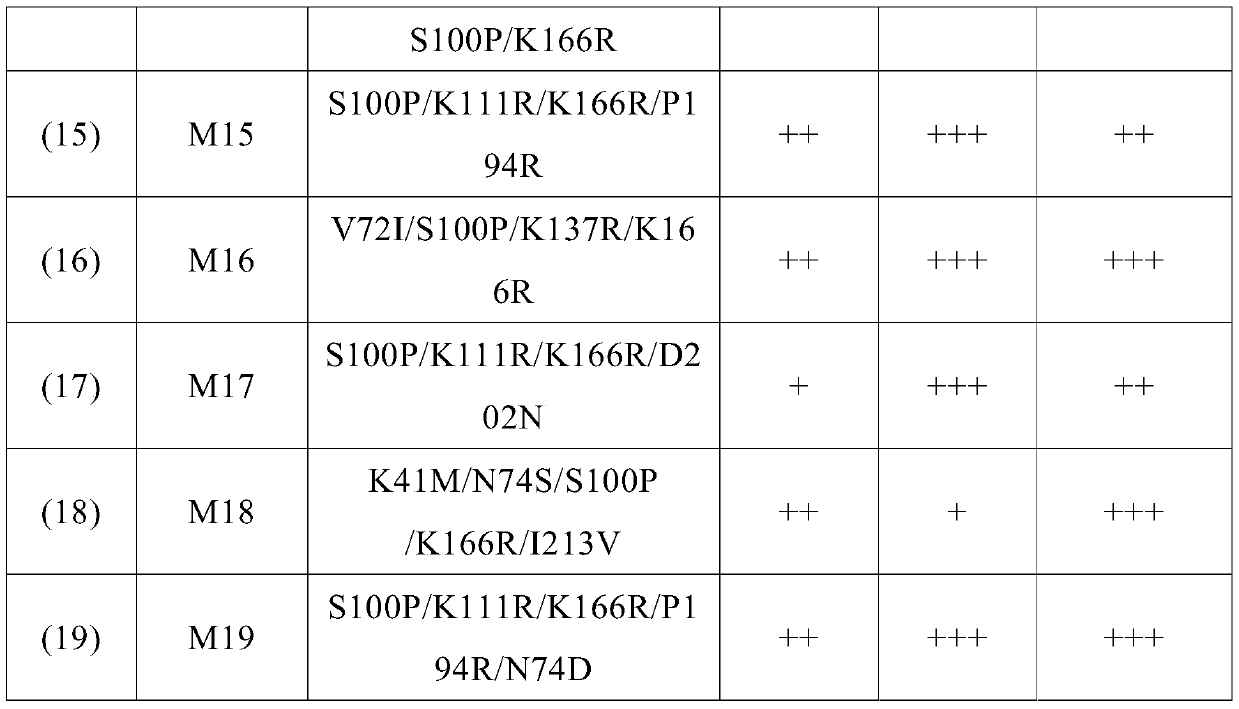

Glucose dehydrogenase mutant with chemical tolerance and application thereof in coenzyme regeneration

ActiveCN111593030AImprove thermal stabilityGood chemical resistanceOxidoreductasesFermentationHigh concentrationHigh activity

The invention relates to a glucose dehydrogenase mutant with chemical tolerance and application thereof in coenzyme regeneration, and belongs to the technical field of bioengineering. The invention provides a bacillus megatherium glucose dehydrogenase mutant, a coding gene thereof, a recombinant expression vector containing a sequence of the gene, a recombinant expression transformant, a preparation method of a mutant enzyme preparation, and practical application of the mutant enzyme preparation in participating in regeneration of coenzyme NAD (P) H in oxidation-reduction reaction. According to the invention, the mutant with significantly improved thermal stability and chemical tolerance is obtained, and the requirements of industrial application are met. The mutant disclosed by the invention not only has high activity and thermal stability, but also has good chemical tolerance, is more beneficial to coenzyme regeneration in a biological catalytic reaction system containing a high-concentration organic cosolvent or a high-concentration substrate / product, and shows a wider application prospect in industrial application.

Owner:EAST CHINA UNIV OF SCI & TECH +1

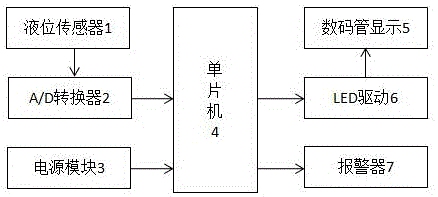

Water tower level control system

InactiveCN106840305AHigh measurement accuracyReduce manufacturing costMachines/enginesLevel indicatorsMicrocontrollerMicrocomputer

The invention discloses a water tower level control system. The water tower level control system comprises a liquid level sensor, an A / D converter, a power module, a single chip microcomputer, a digital tube display, an LED driver and an alarm, and is characterized in that the liquid level sensor achieves conversion of liquid level information into a voltage signal; the voltage signal output by the liquid level sensor passes through the A / D converter and then is sent to the single chip microcomputer; the single chip microcomputer adopts an AT89C51 chip, and achieves reception and data processing of the liquid level information and output of the liquid level information to a digital tube; the alarm makes an alarm when the single chip microcomputer detects that the liquid level surpasses a limit; the single chip microcomputer processes and then outputs liquid level data to the digital tube display.

Owner:南宁市高光信息技术有限公司

A kind of chabazite molecular sieve and its synthesis method and application

ActiveCN111960434BReasonably acidicGood hydrothermal stabilityMaterial nanotechnologyMolecular sieve catalystsChemical synthesisPtru catalyst

The invention discloses a CHA type chabazite molecular sieve as well as its synthesis method and application, belonging to the field of chemical synthesis technology and its application. Adopt N,N,N-trialkyl-N-phenyl quaternary ammonium salt or quaternary ammonium base compound to be organic template synthesis CHA type chabazite molecular sieve, the silicon dioxide of described CHA type chabazite molecular sieve is relative to the aluminum oxide The molar ratio ranges from 5 to 80, the average grain diameter ≤ 500nm, the total specific surface area measured by BET method ≥ 400m2 / g, the total pore volume ≥ 0.20ml / g, the micropore pore volume ≥ 0.10ml / g, crystal plane (‑210) The grain diameter of the direction is 50-160nm. The molecular sieve of the present invention has high hydrothermal stability without large crystal grains, and exhibits high nitrogen oxide reduction properties after exposure to high temperature and high humidity, especially in the temperature range of 200°C to 550°C Catalysts with high NOx reduction properties.

Owner:CHINA CATALYST HLDG CO LTD

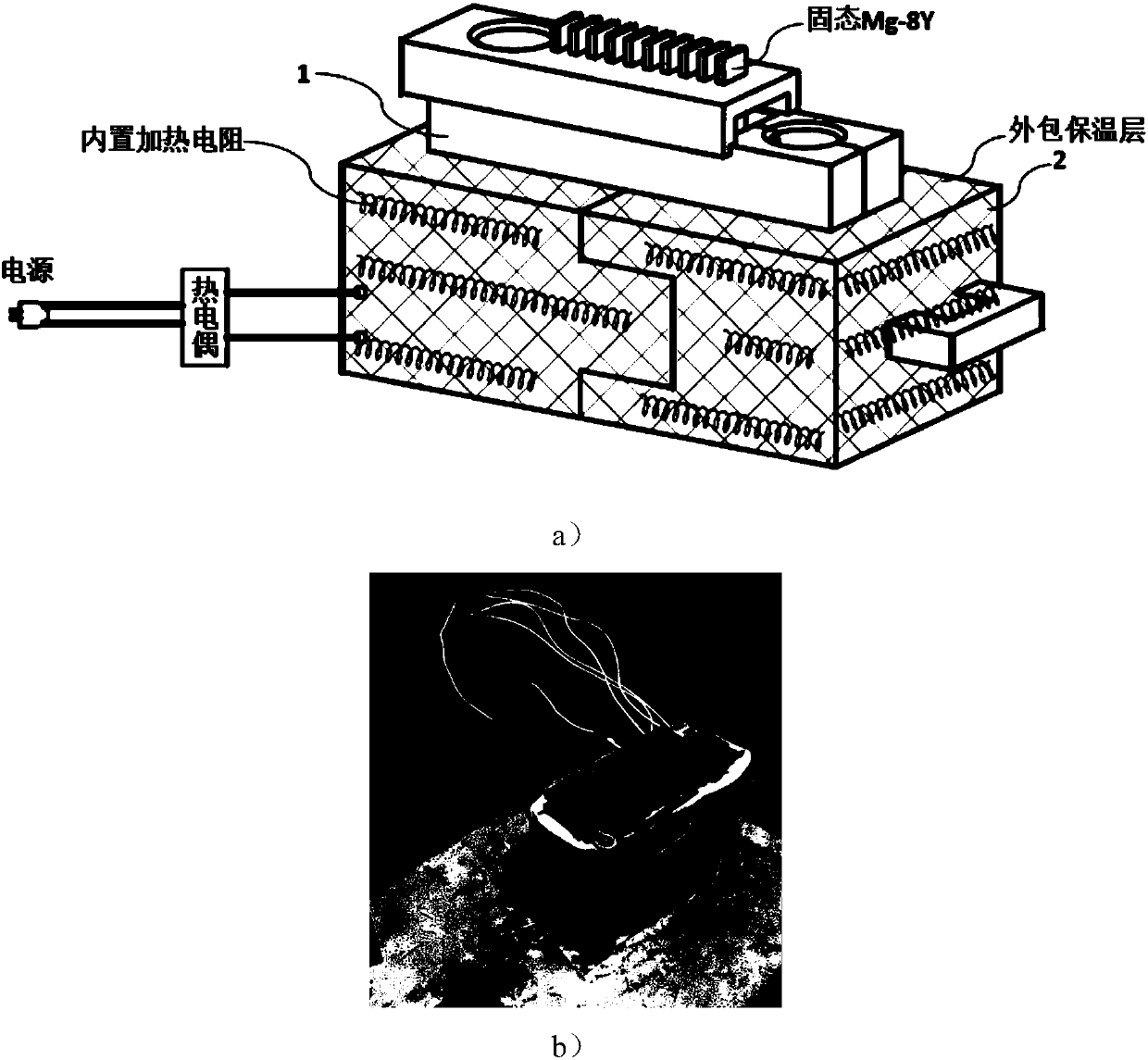

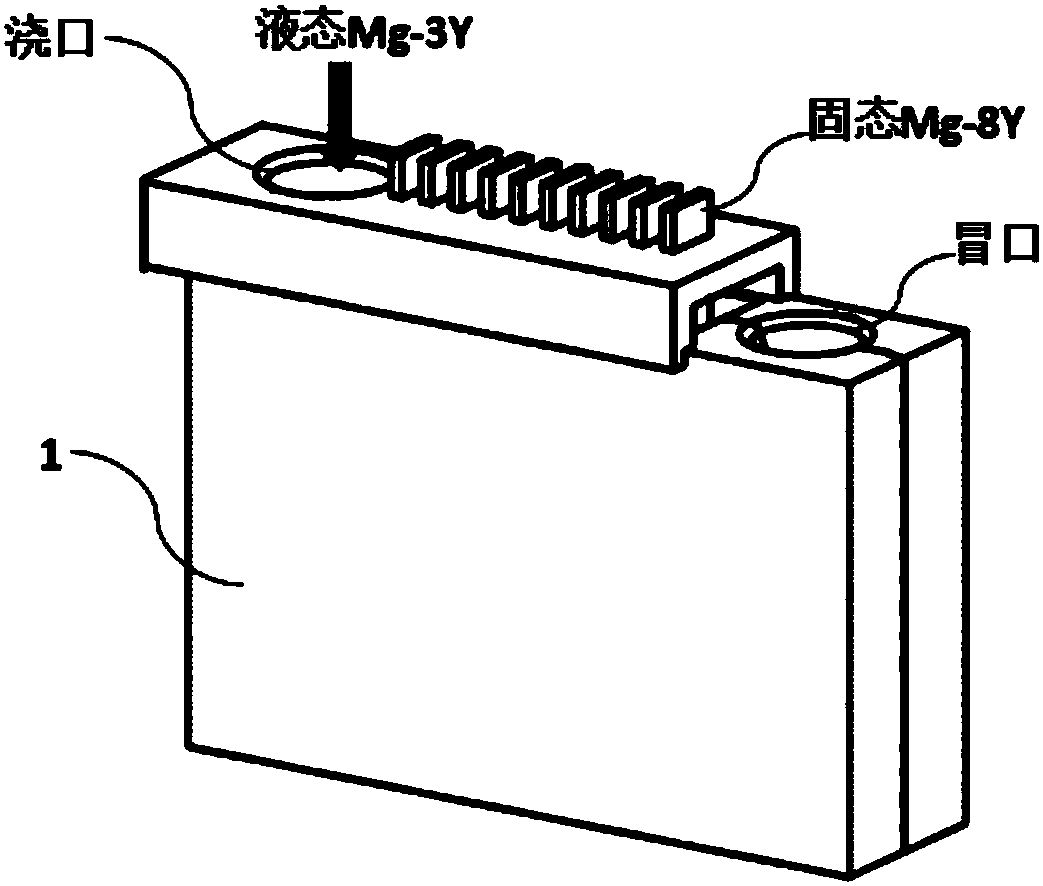

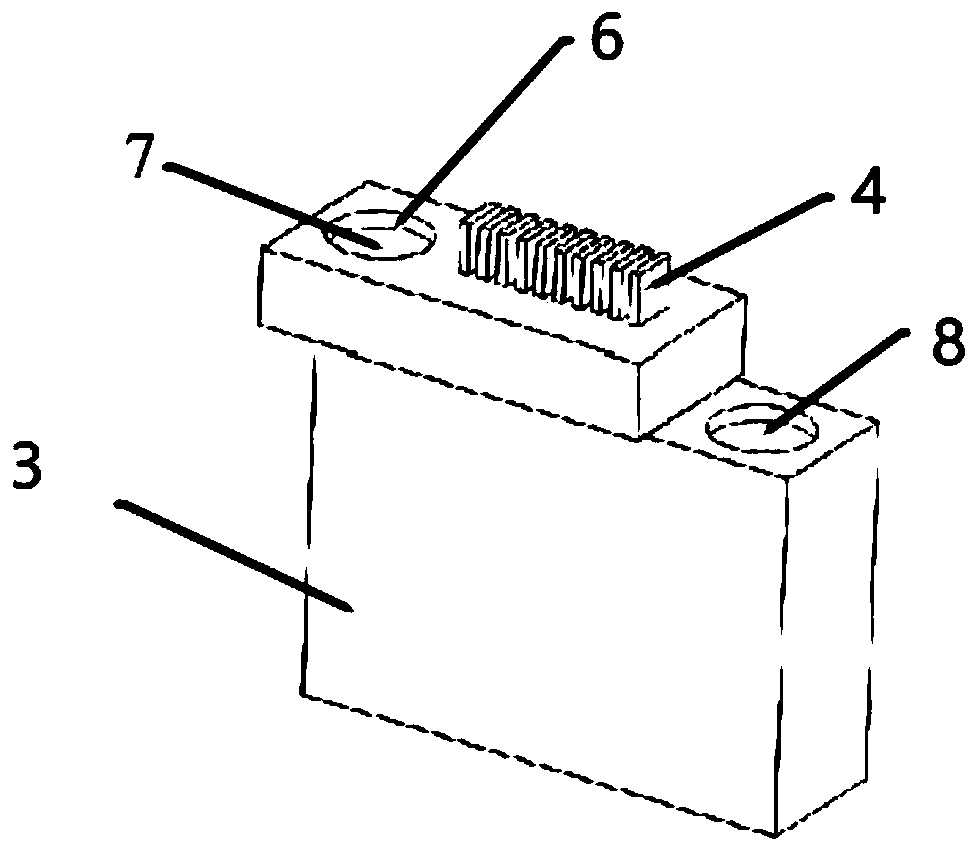

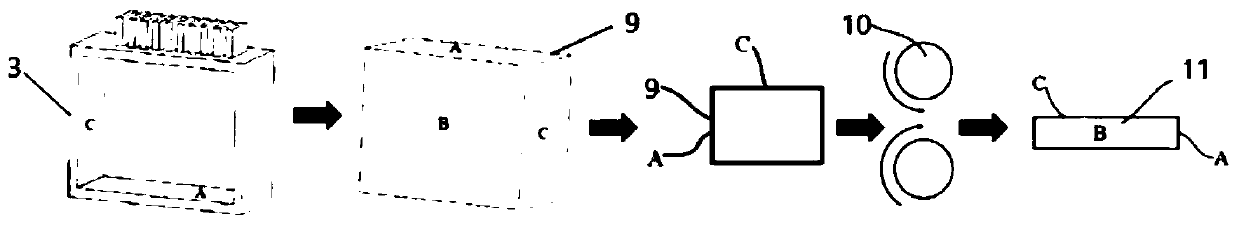

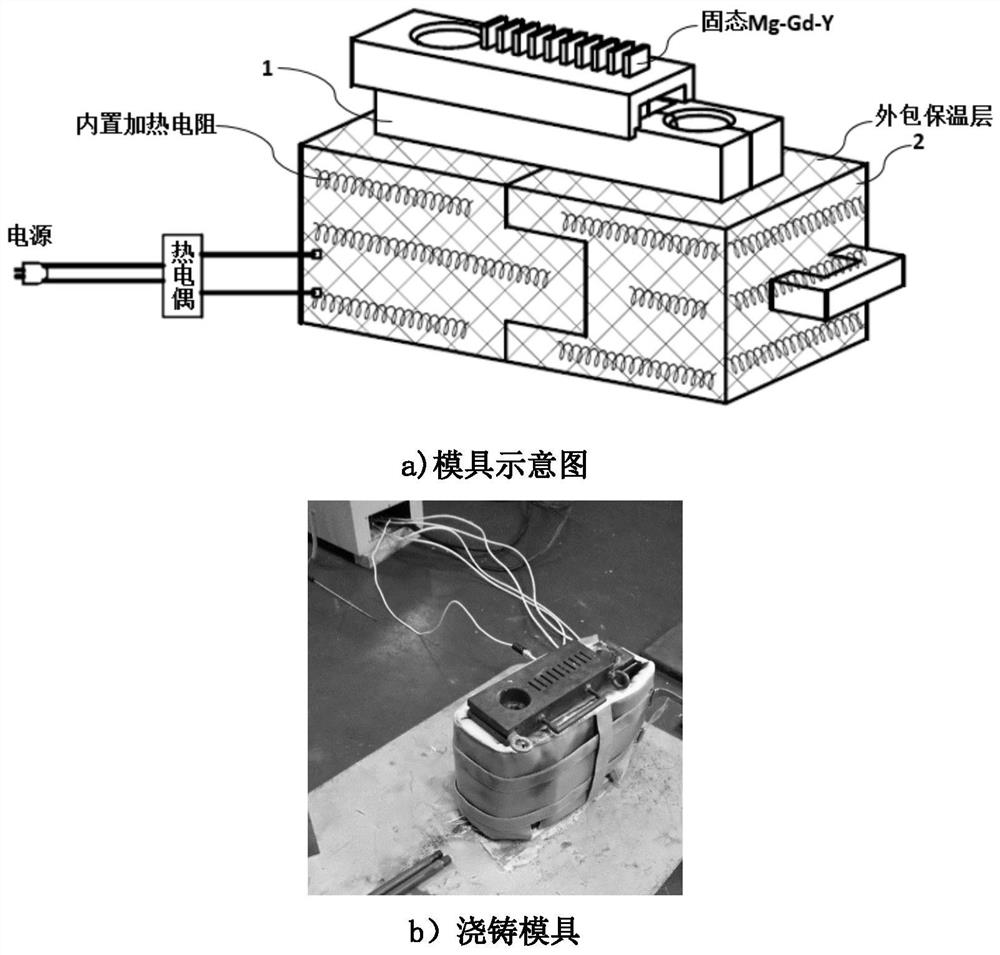

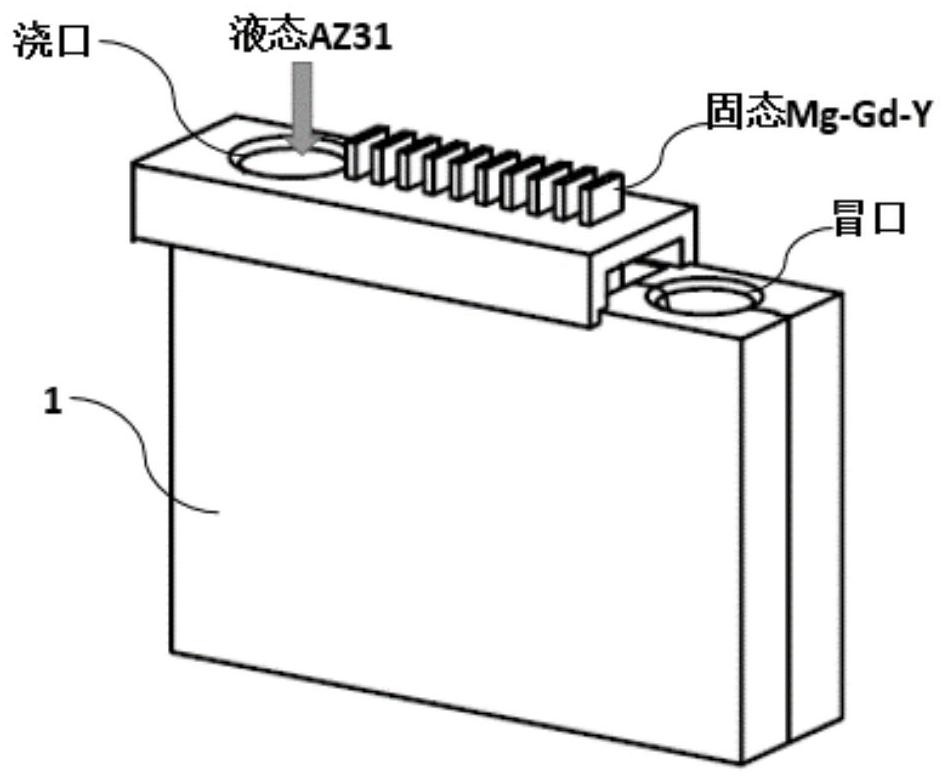

Preparation method of multi-scale precipitation laminated structure magnesium alloy

A preparation method of a multi-scale precipitation laminated structure magnesium alloy comprises the procedures of pretreatment, casting, multi-scale precipitation and the like, and comprises the following steps: selecting two or more magnesium alloys with different strengthening effect behaviors, and carrying out solid-liquid inlay casting to form a multi-layer composite magnesium alloy. And then through rolling and subsequent aging treatment, a multi-scale precipitated phase is formed among all laminates, and a multi-scale precipitation reinforced laminated structure magnesium alloy composite material is obtained. The toughness and strength of a soft phase and a hard phase of the prepared alloy are obtained to a certain extent, and the high-strength and high-toughness double-system or multi-system precipitation strengthened magnesium alloy with an excellent comprehensive performance is obtained. The precipitation reinforced magnesium alloy has good heat resistance, and the toughnessis far higher than that of a conventional uniformly precipitated magnesium alloy. And the mixed precipitation microstructure has no obvious directivity and is suitable for being applied to multidirectional stressed components.

Owner:NANJING UNIV OF SCI & TECH

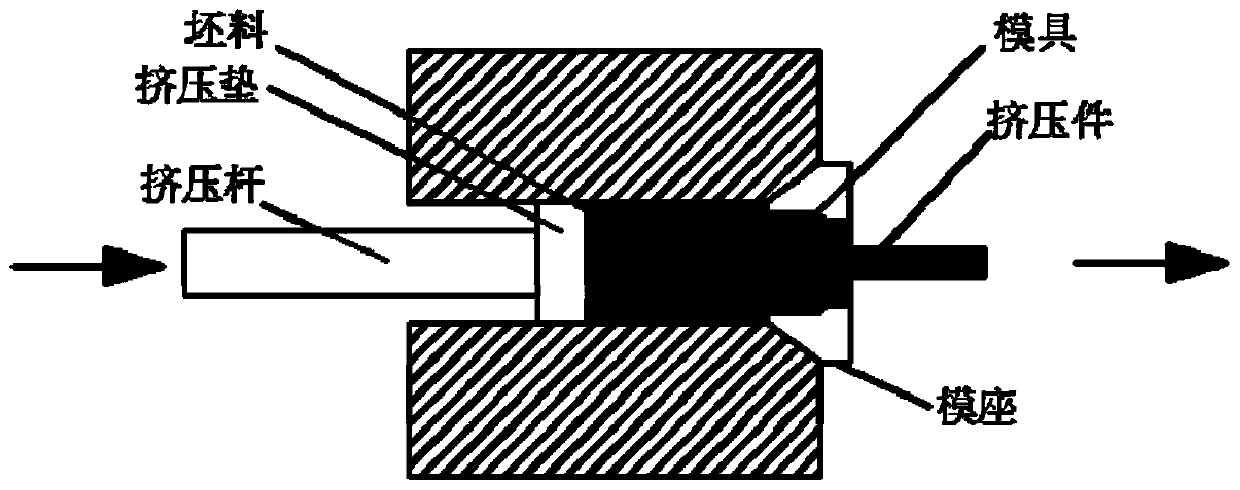

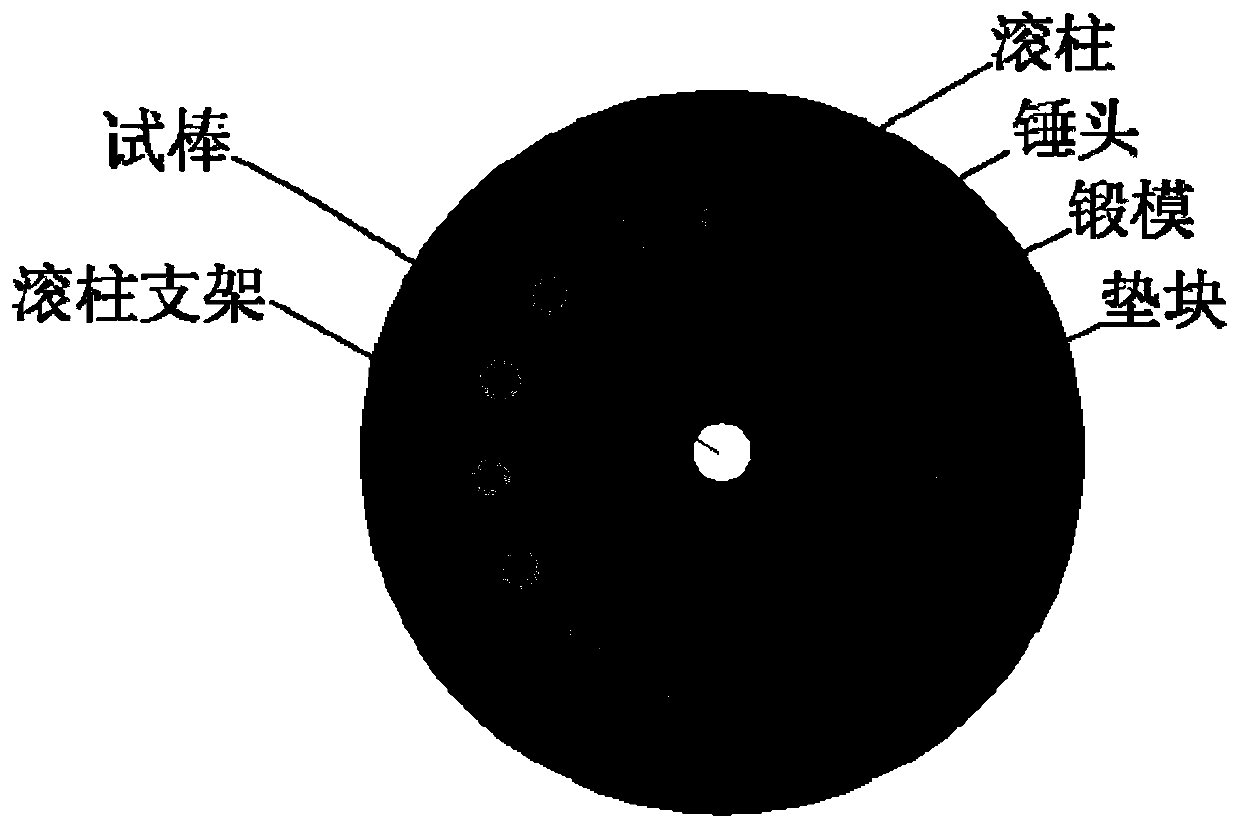

Preparation method of industrial pure aluminum wire

ActiveCN111378849ALarge structureIncrease flexibilityConductive materialMetal/alloy conductorsElectro conductivityElectron transmission

The invention relates to a preparation method of an industrial pure aluminum wire. The preparation method of the industrial pure aluminum wire comprises a three-step process of melt purification treatment, hot extrusion treatment and rotary forging treatment, and particularly the low temperature rotary forging treatment process is used after the melt purification treatment and the hot extrusion treatment. According to the preparation method of the industrial pure aluminum wire, by constructing fine elongated grains in materials, the radial size of the fine elongated grains is small and beneficial to the improvement of the strength of the materials, the axial size greatly increases the electron transport distance, the scattering effect of the grain boundary on an electron is reduced, the conductivity of the materials is improved, the mechanical properties are further improved, so that a conductive aluminum alloy with high dimensional accuracy, good surface finish and excellent conductivity and strength is obtained.

Owner:NANJING UNIV OF SCI & TECH

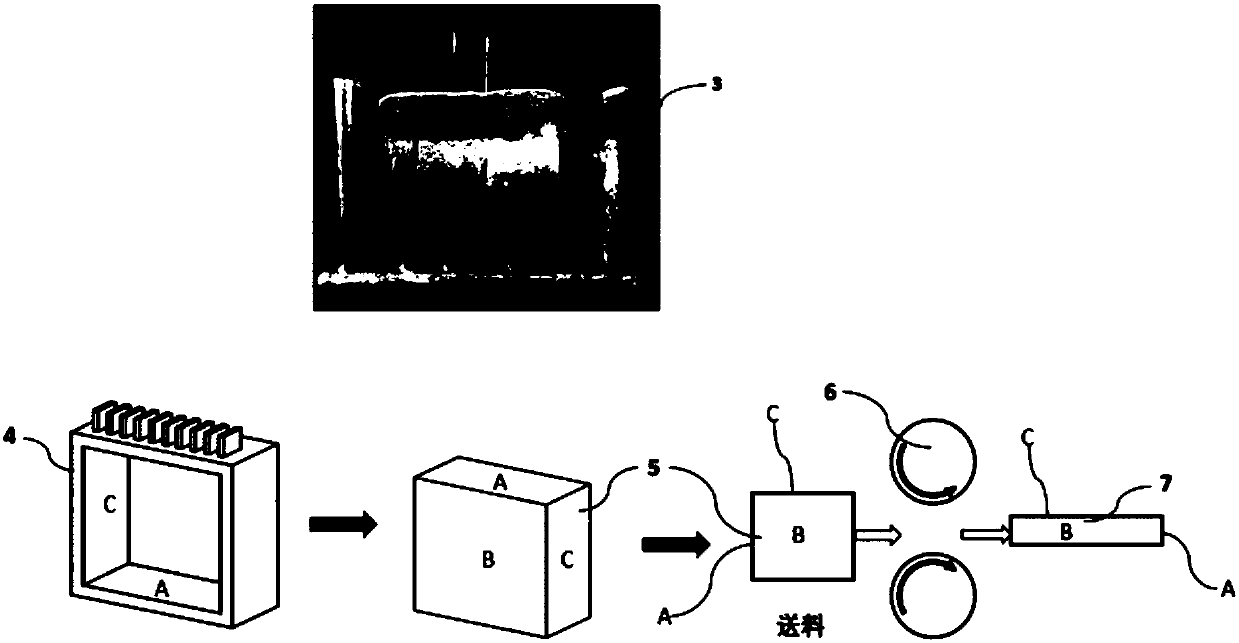

Preparation method of multi-crystal-granule-size multi-layer high-entropy alloy

ActiveCN110253000AGreat microstructural design flexibilityImprove performanceMaterials preparationHigh entropy alloys

The invention belongs to the field of material preparation, and particularly relates to a preparation method of a multi-crystal-granule-size multi-layer high-entropy alloy. The preparation method of the multi-crystal-granule-size multi-layer high-entropy alloy comprises the following steps of (1) pretreating: selecting more than two high-entropy alloys, wherein each high-entropy alloy is a single phase and cannot happen phase change in the heating process, and each high-entropy alloy at least contains one FCC and BCC-structure single phase; (2) casting: carrying out solid-liquid inlaying and casting on the liquid-state high-entropy alloy and the solid-state high-entropy alloy, and forming a multi-layer high-entropy alloy; (3) rolling: cutting the multi-layer high-entropy alloy to obtain a multi-layer high-entropy alloy block, and rolling to obtain a rolling-state multi-layer high-entropy alloy; and (4) forming a multi-crystal-granule-size: carrying out heat treatment on the rolling-state multi-layer high-entropy alloy, and obtaining the multi-crystal-granule-size multi-layer high-entropy alloy. The preparation method of the multi-crystal-granule-size multi-layer high-entropy alloy provided by the invention adopts a multi-alloy solid-liquid mixed casting and forming method, the prepared high-entropy alloy has toughness and strength of a soft phase and a hard phase to a certain degree, and the high-strength high-toughness double-system or multi-system refined crystalline strengthening high-entropy alloy with a favorable combination property is obtained.

Owner:NANJING UNIV OF SCI & TECH

A kind of preparation method of multi-grain scale multilayer magnesium alloy

ActiveCN110343983BImprove performanceLarge structureLamination ancillary operationsLaminationMetallurgyAlloy composite

The invention discloses a preparation method of a multi-grain-scale multilayer magnesium alloy, which includes four steps of pretreatment, casting, rolling, and multi-grain scale formation. Two or more rare earth magnesium alloys and deformed magnesium alloys are selected. , and perform solid-liquid inlay casting to form a multilayer composite magnesium alloy. Then, through rolling and subsequent annealing treatment, multi-grain scales are formed between each layer, and a large multi-grain size strengthened layer heterogeneous magnesium alloy composite material is obtained.

Owner:NANJING UNIV OF SCI & TECH

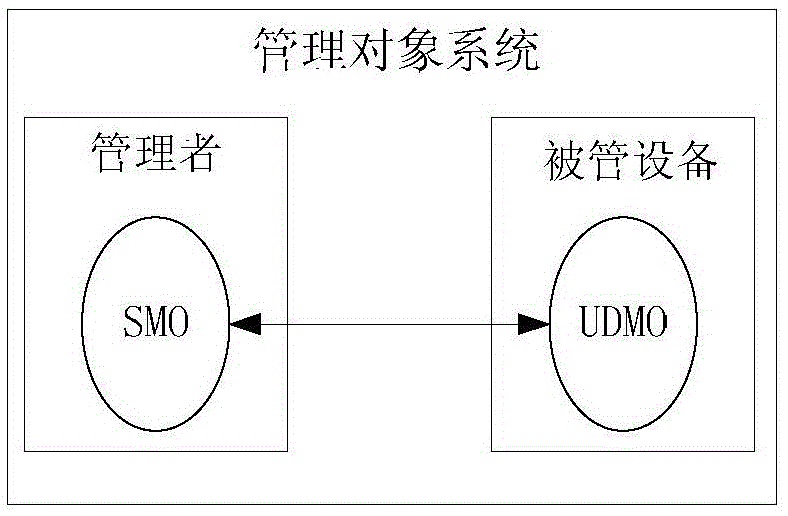

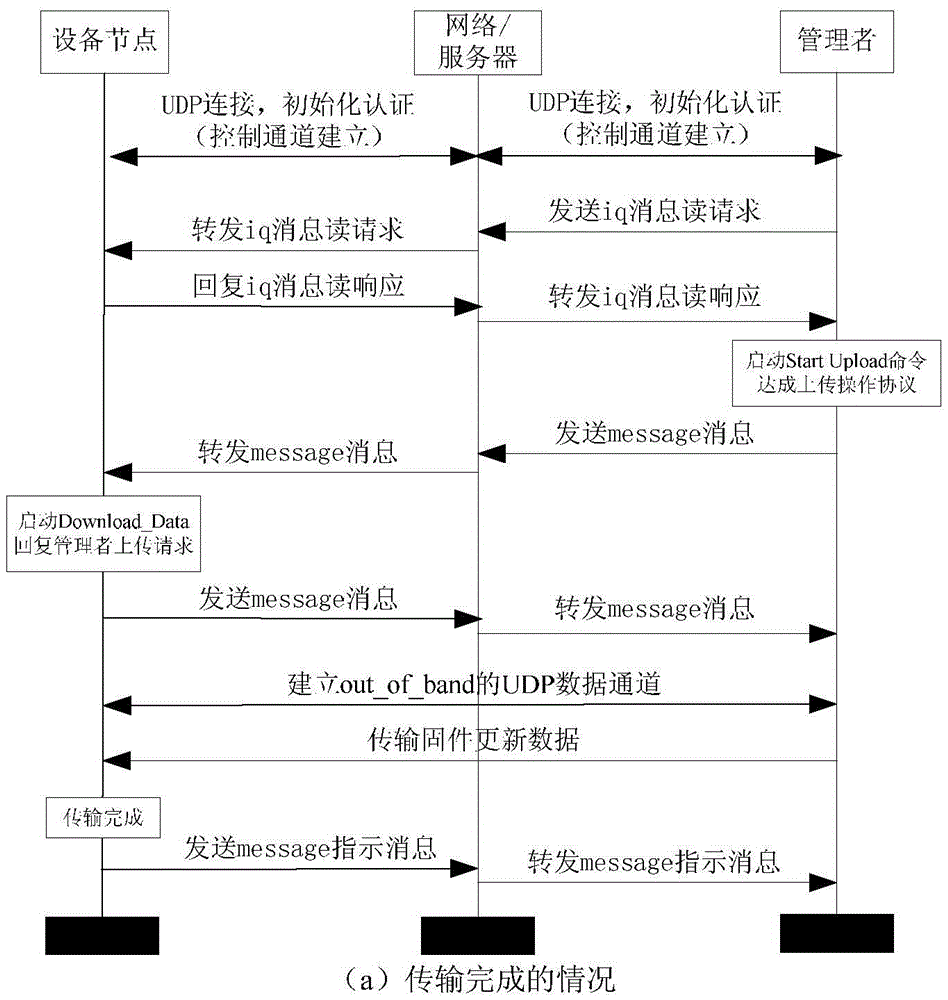

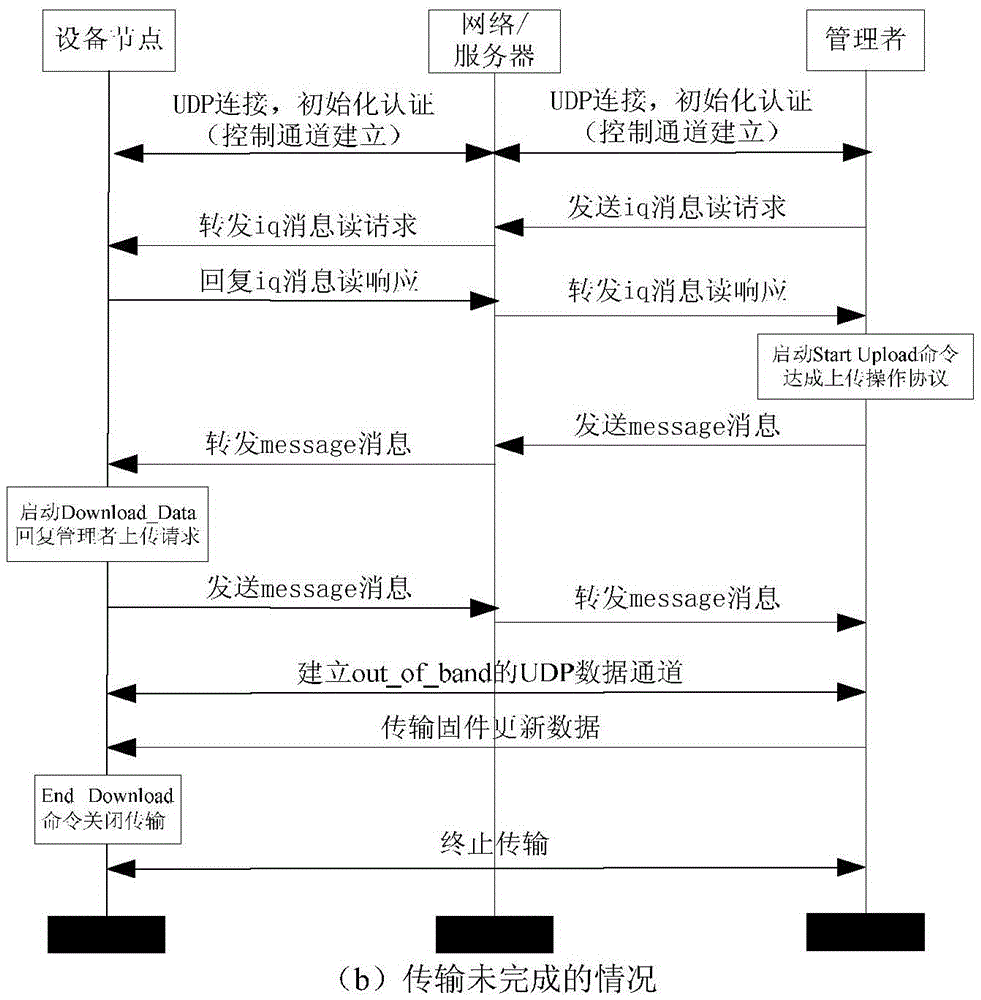

Firmware update method for wireless sensor network based on xmpp

ActiveCN103442349BQuality improvementImprove efficiencyNetwork topologiesNetwork data managementSystems managementManagement object

The invention provides a wireless sensor network firmware updating method based on an XMPP, and relates to the technical field of wireless sensor networks. According to the wireless sensor network firmware updating method, on the basis of an XMPP series protocol standard, corresponding expansion is carried out on a core protocol of the XMPP; a manager system is designed to be provided with a system management object according to application requirements of an industrial wireless sensor network and by means of characteristics of the object; each equipment node in the wireless sensor network is provided with a firmware updating management object and management of the network is achieved through a mode of operating the management object. The wireless sensor network firmware updating method can effectively guarantee real-time performance of the industrial wireless sensor network and improve overall management quality and efficiency of the network.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

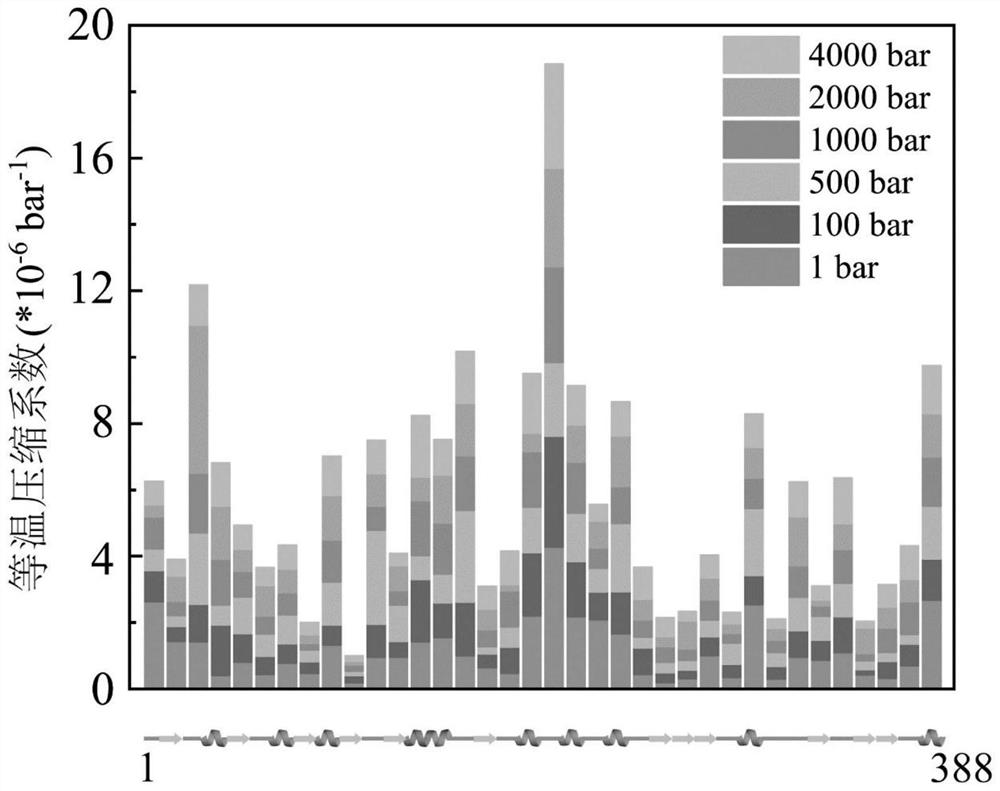

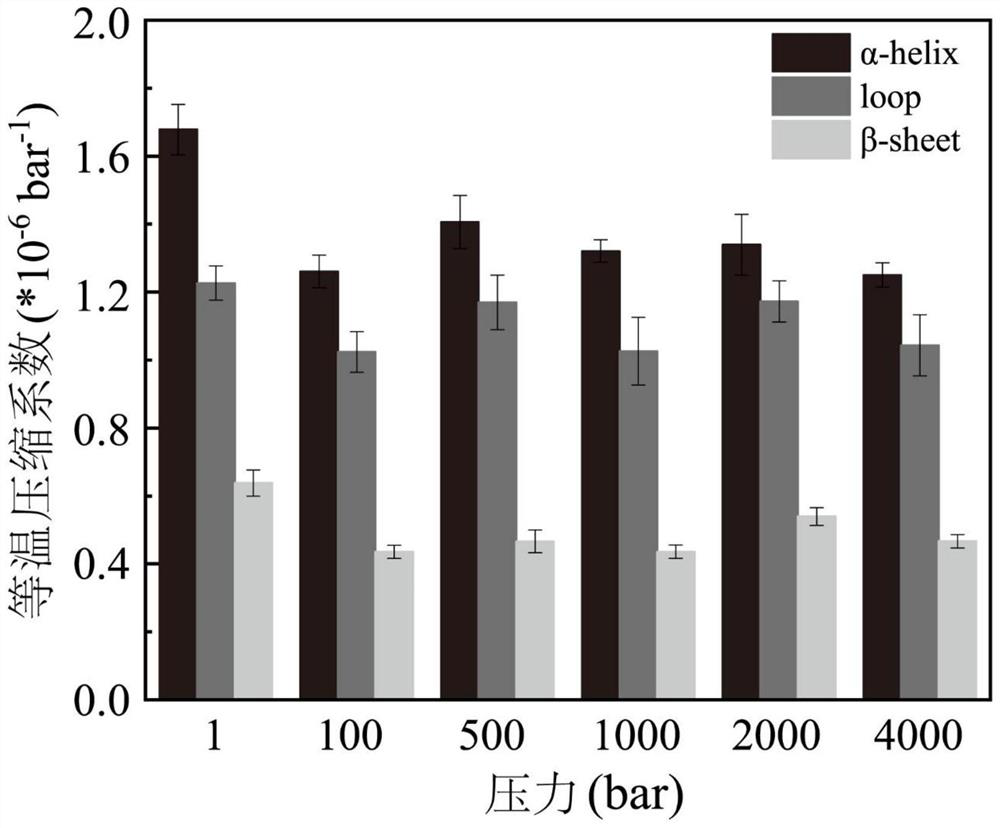

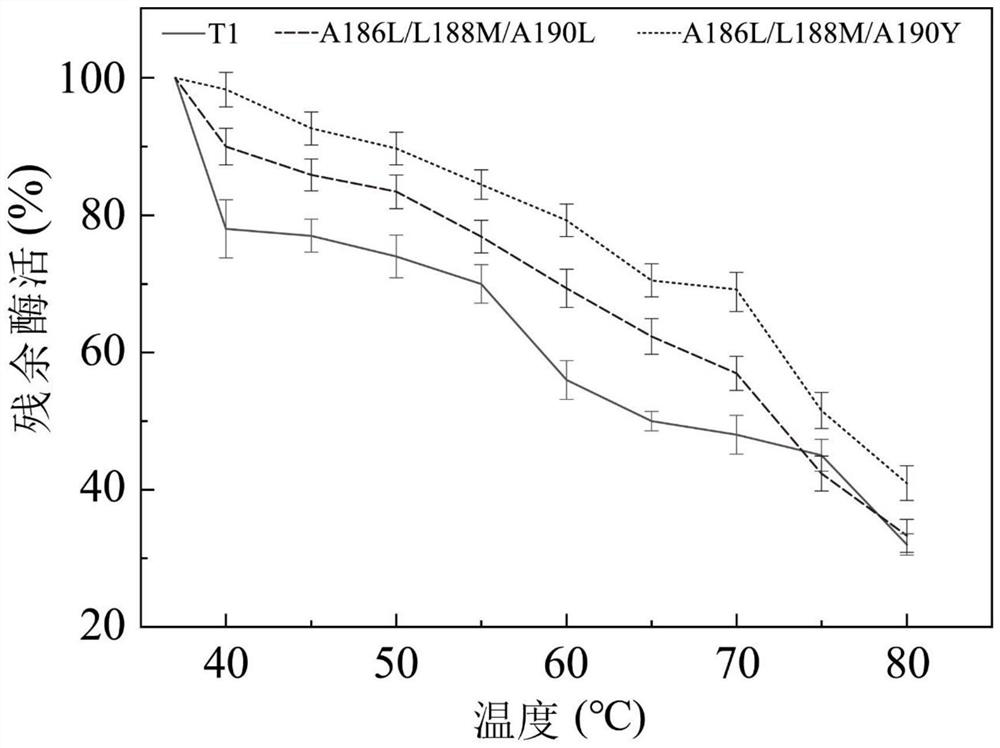

Method for redesigning enzyme based on isothermal compression coefficient disturbance, application and mutant screened by method

ActiveCN114220492AImprove stabilityHigh activityHydrolasesChemoinformaticsProtein engineeringEngineered genetic

The invention relates to a method for redesigning enzyme based on isothermal compression coefficient disturbance, application and a mutant screened by the method, and belongs to the technical fields of computational chemistry, bioinformatics, genetic engineering and protein engineering. The method comprises the following steps: screening out a high-fluctuation region, far away from an active center, on the surface of protein through isothermal compression coefficient disturbance, carrying out virtual saturation mutation on amino acid on the screened high-fluctuation region, and screening out mutants of which the Gibbs free energy is reduced after mutation, so as to obtain redesigned enzyme; wherein the disturbance mode of the isothermal compression coefficient is pressurization. The method provided by the invention overcomes the problems of lack of globality in screening of high-fluctuation regions and incapability of simultaneously improving the stability and activity of the enzyme in the prior art, provides a widely applicable method for design optimization of the enzyme, and improves the application value of the enzyme in industry.

Owner:JIANGNAN UNIV

A Routing Method for IPv6 Industrial Wireless Sensor Networks Based on Deterministic Scheduling

ActiveCN103118413BImprove communication performanceMeeting the needs of industrial applicationsNetwork topologiesMobile wireless sensor networkWireless sensor networking

The invention relates to an IPv6 (Internet protocol version 6) industrial wireless sensor network routing method based on definiteness scheduling and belongs to the technical field of industrial wireless sensor networks. The method is based on 6LoWPAN and definiteness scheduling of industrial wireless sensor networks, and adaptation layer protocol and neighbor discovery protocol are modified according to 6LoWPAN serial protocol standards. Scheduling time and channel quality are used as path selection standards according to application requirements of industrial wireless sensor networks. An optimal path simultaneously satisfying two routing standards is selected for data with marked definiteness features in a distributed manner, and accordingly definiteness, instantaneity and reliability requirements of industrial application are met. By the method, definiteness of an industrial wireless sensor network can be guaranteed effectively, and overall communication performance of the network is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

A preparation method of multi-scale precipitation heterogeneous layered structure aluminum alloy

The invention provides a method for preparing a multi-scale precipitation heterogeneous layered structure aluminum alloy material, including: pretreatment, casting and multi-scale precipitation, etc., selecting two or more aluminum alloys with different age hardening behaviors, and solidifying Liquid inlay casting to form a multi-layer composite aluminum alloy block. Then, through rolling and subsequent aging treatment, multi-scale precipitates are formed between different layers, and a multi-scale precipitated heterogeneous layered structure aluminum alloy material is obtained.

Owner:NANJING UNIV OF SCI & TECH

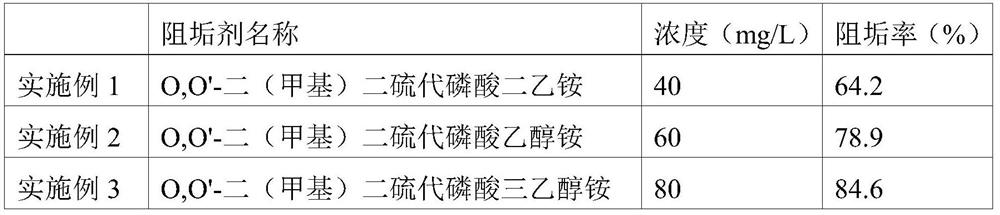

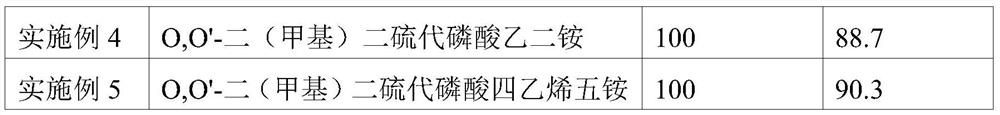

A high-efficiency scale inhibitor and its application

ActiveCN110028170BReduce usageImprove efficiencyScale removal and water softeningBiochemical engineeringEnvironmental engineering

The invention discloses a high-efficiency scale inhibitor and an application thereof, aiming to solve the problem that the existing scale inhibitors for industrial circulating water are generally complex scale inhibitors mixed with various substances and have a large amount of use. This application proposes for the first time that O,O'-di(hydrocarbyl)dithiophosphate ammonium salt is used as a scale inhibitor, which has the advantages of single component and less dosage, and can effectively overcome the defects of existing composite scale inhibitors . At the same time, the scale inhibitor of the present application has high efficiency, good water solubility, and is easy to use, which can meet the needs of industrial applications. Further, the application claims the application of O, O'-bis(hydrocarbyl) dithiophosphate ammonium salt as a scale inhibitor, which broadens the application field of O, O'-di(hydrocarbyl) dithiophosphate ammonium salt.

Owner:四川文理学院

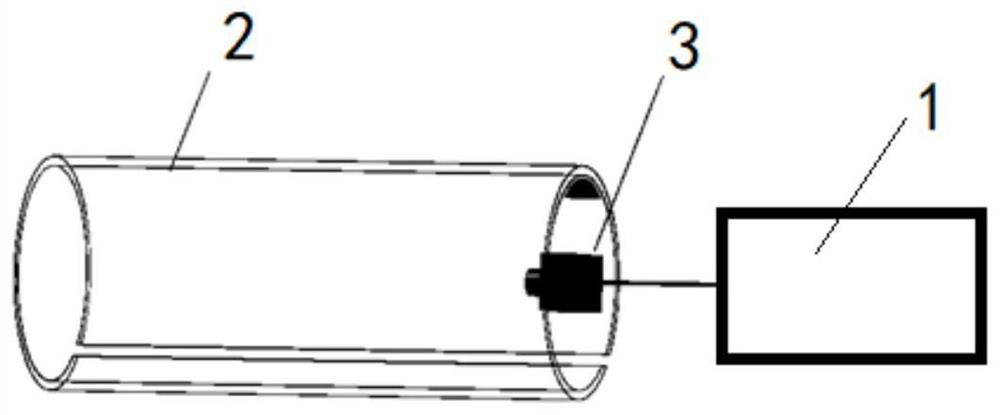

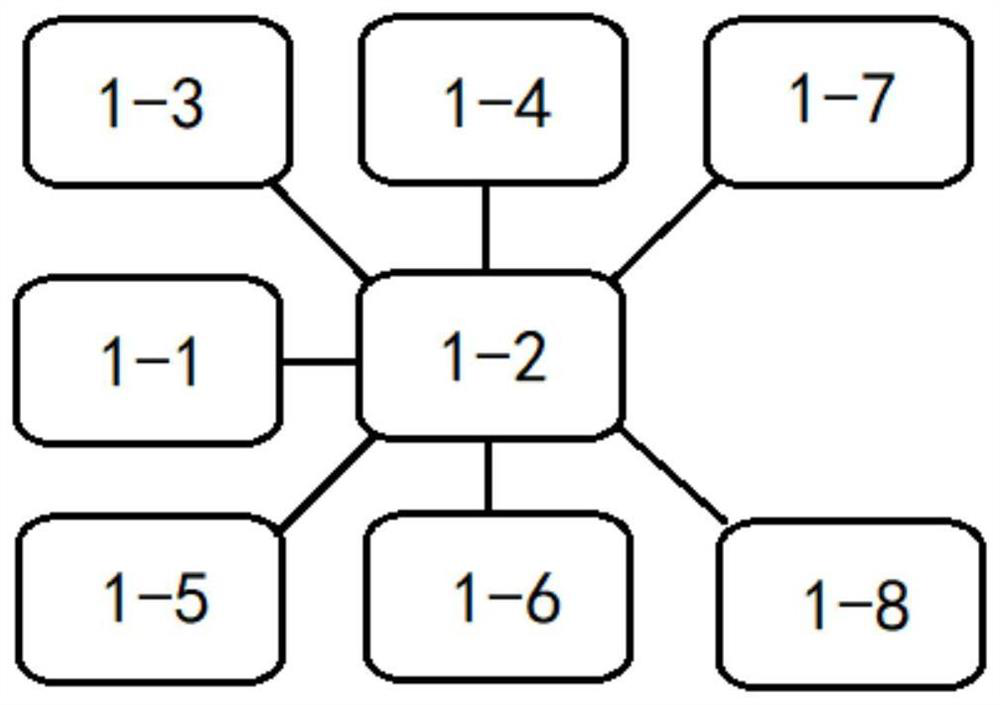

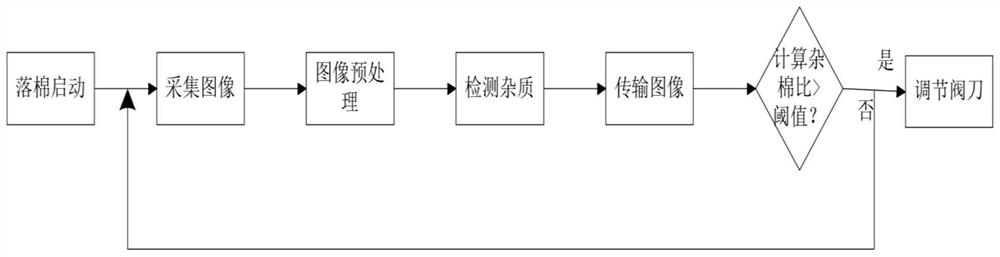

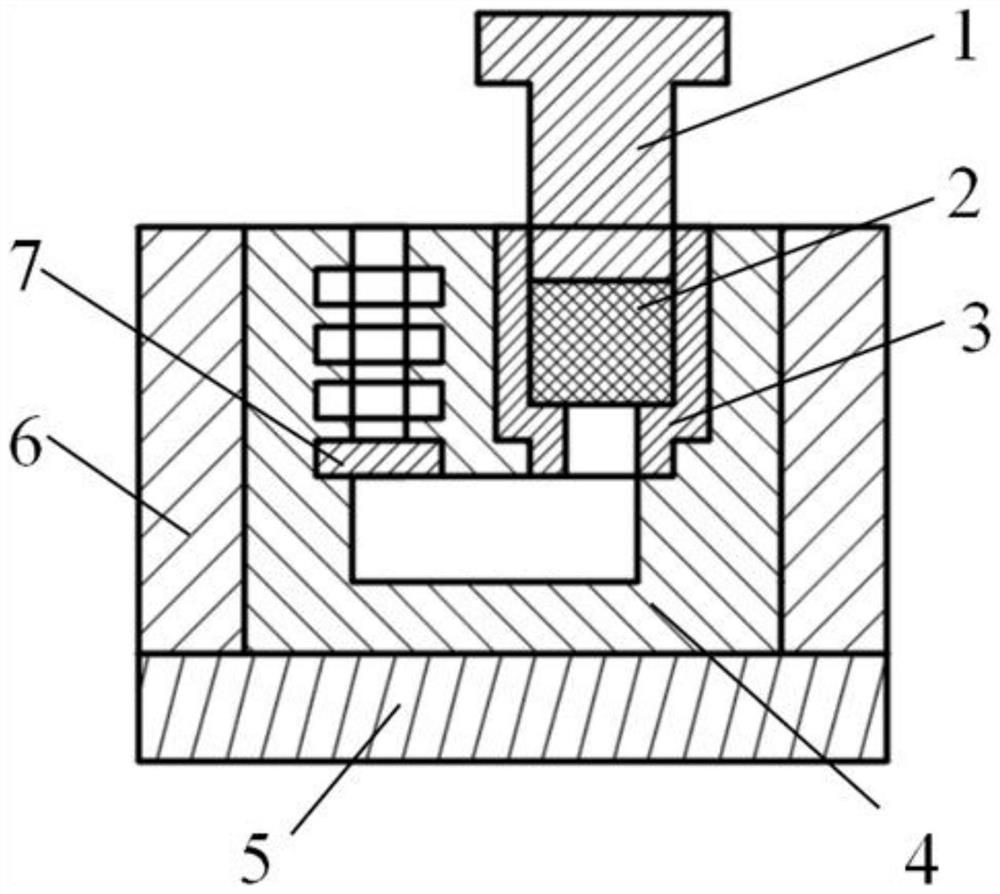

Cotton impurity detection method and system based on machine vision

PendingCN114648524AAccelerateReduce the amount of parametersImage enhancementImage analysisWoven fabricNetwork architecture

The invention discloses a cotton impurity detection system and method based on machine vision, and belongs to the technical field of cotton impurity image detection. And a machine vision and deep learning technology is utilized, a cotton miscellaneous data set is adopted to train a convolutional neural network, then a weight is output, an optimized convolutional neural network is obtained, and image information of actually detected noil is identified. The convolutional neural network has a complementary search technology and a searchable lightweight and efficient network architecture, has the characteristics of low parameter, high performance and high speed, and can meet the requirements of industrial application. On the basis, the parameter layer and the channel number can be adjusted, the parameter quantity is reduced, and the detection speed is improved, so that the method is more suitable for impurity image detection and classification. The method is high in automation degree, a previous manual sorting mode is replaced, the efficiency is improved, and the cost is reduced. Meanwhile, the cotton impurity detection efficiency and quality are improved, more technical supports are provided for subsequent impurity removal, the finished product quality of cotton textiles is improved, and the method has good application prospects.

Owner:XI'AN POLYTECHNIC UNIVERSITY

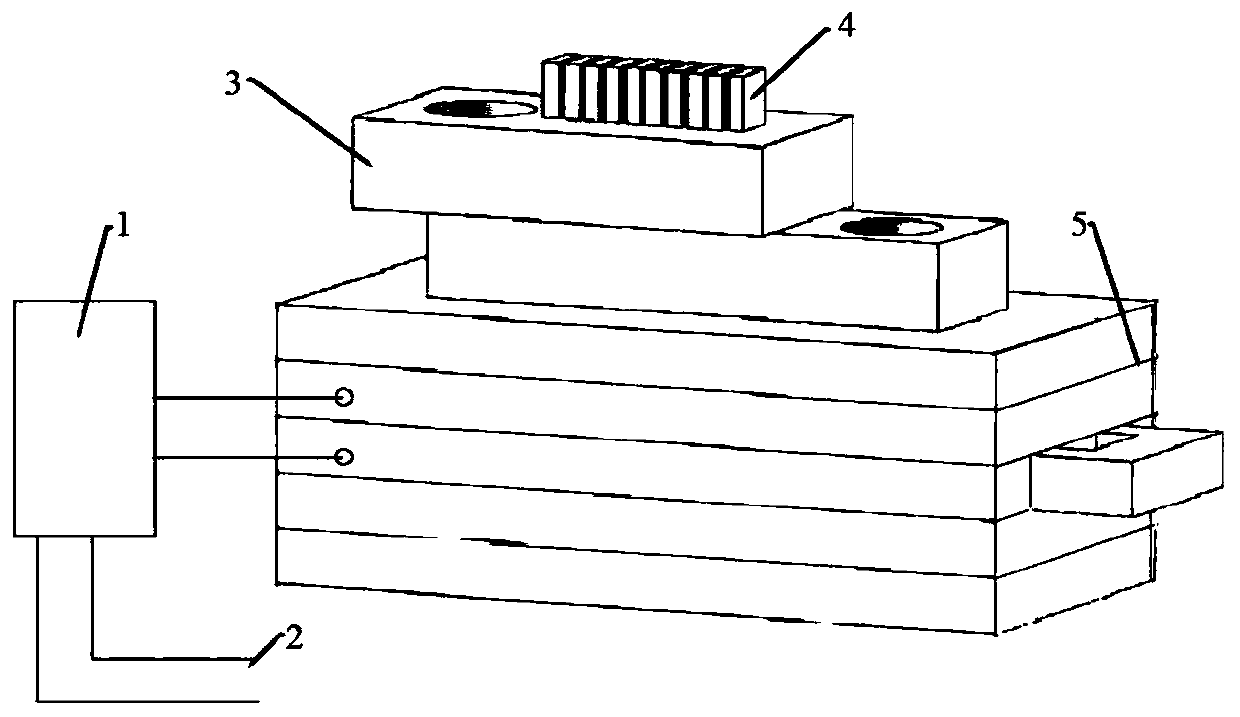

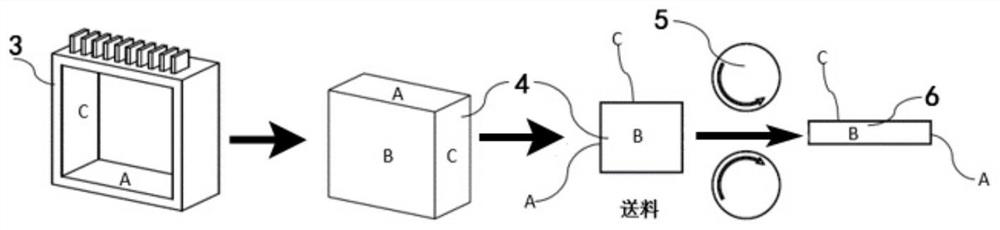

Multi-extrusion device for preparing layered isomeric magnesium alloy and method for preparing layered isomeric magnesium alloy by utilizing device

The invention belongs to the field of material preparation, and particularly relates to a multi-extrusion device for preparing a layered isomeric magnesium alloy and a method for preparing the layeredisomeric magnesium alloy by utilizing the device A plurality of as-cast magnesium alloy ingot blanks subjected to homogenization treatment are cut into square shapes and subjected to preheating treatment, then the square-shaped as-cast magnesium alloy ingot blanks are put into a mold, the blanks are pressed into a cavity under the acting force applied by a punch, and the punch is extruded to continuously move downwards to push the alloy blanks to continuously enter the cavity. After the cavity is completely filled with a blank, an extrusion insert is taken out, an insert with a larger extrusion ratio is replaced, and a limiting block at the outlet part of the blank is adjusted upwards, so that the magnesium alloy which is forced to be extruded obtains enough space, and the extrusion experiment is repeated. In addition, the insert is replaced with the insert with the larger extrusion ratio, the position of the limiting block is adjusted upwards again, and then the extrusion experimentis repeated again. Through repeating the processes, the layered isomeric magnesium alloy with excellent comprehensive performance, high strength and high toughness is finally obtained.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com