Preparation method of industrial pure aluminum wire

A technology of industrial pure aluminum and industrial pure titanium, applied in conductors, conductive materials, conductive materials, etc., can solve problems such as difficulty in meeting industrial needs, limited total drawing deformation, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

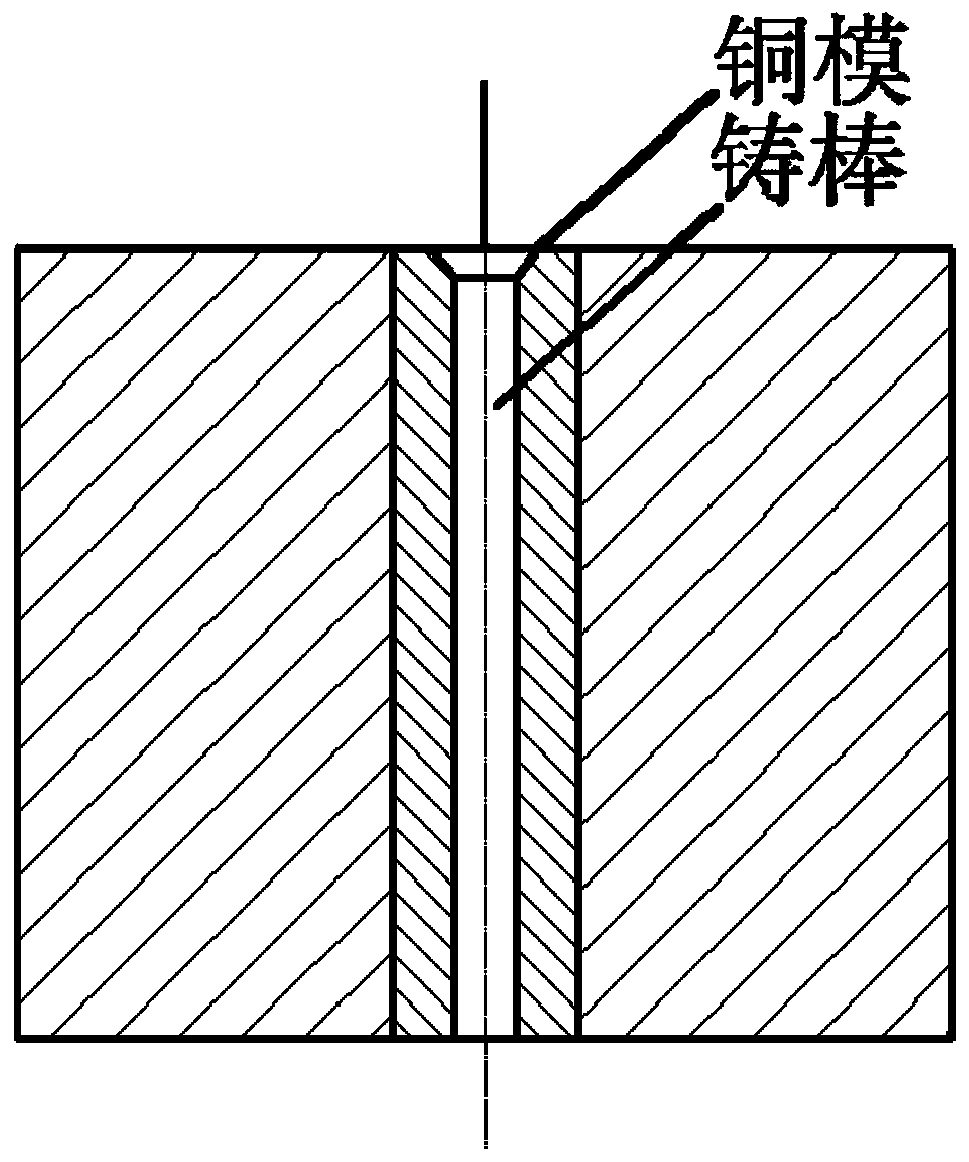

[0037] Step 1, melt purification treatment: select industrial pure aluminum AA1070 as the raw material, put the industrial pure aluminum in a resistance furnace and melt it to 720°C, then add 50ppm of industrial pure titanium to the melt and perform mechanical stirring, then add 300ppm of B element treatment, in which B element is added to the melt in the form of Al-3B master alloy. The melt is kept warm for 15 minutes so that the impurity elements form borides and precipitate to the bottom of the melt, realizing the separation of the impurity elements from the melt. After the heat preservation is over, the industrial pure aluminum liquid is cast into copper molds of different sizes to form cast rod.

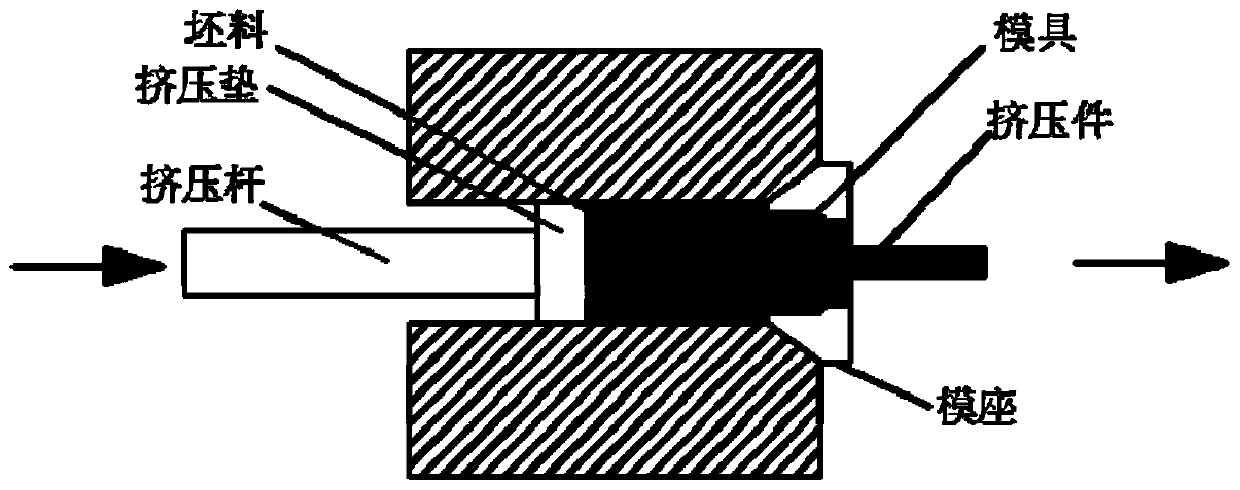

[0038] Step 2, hot extrusion deformation: put the industrial pure aluminum cast rod obtained after purification treatment in a heat treatment furnace for heat preservation. The dimension of the bar after pressing is

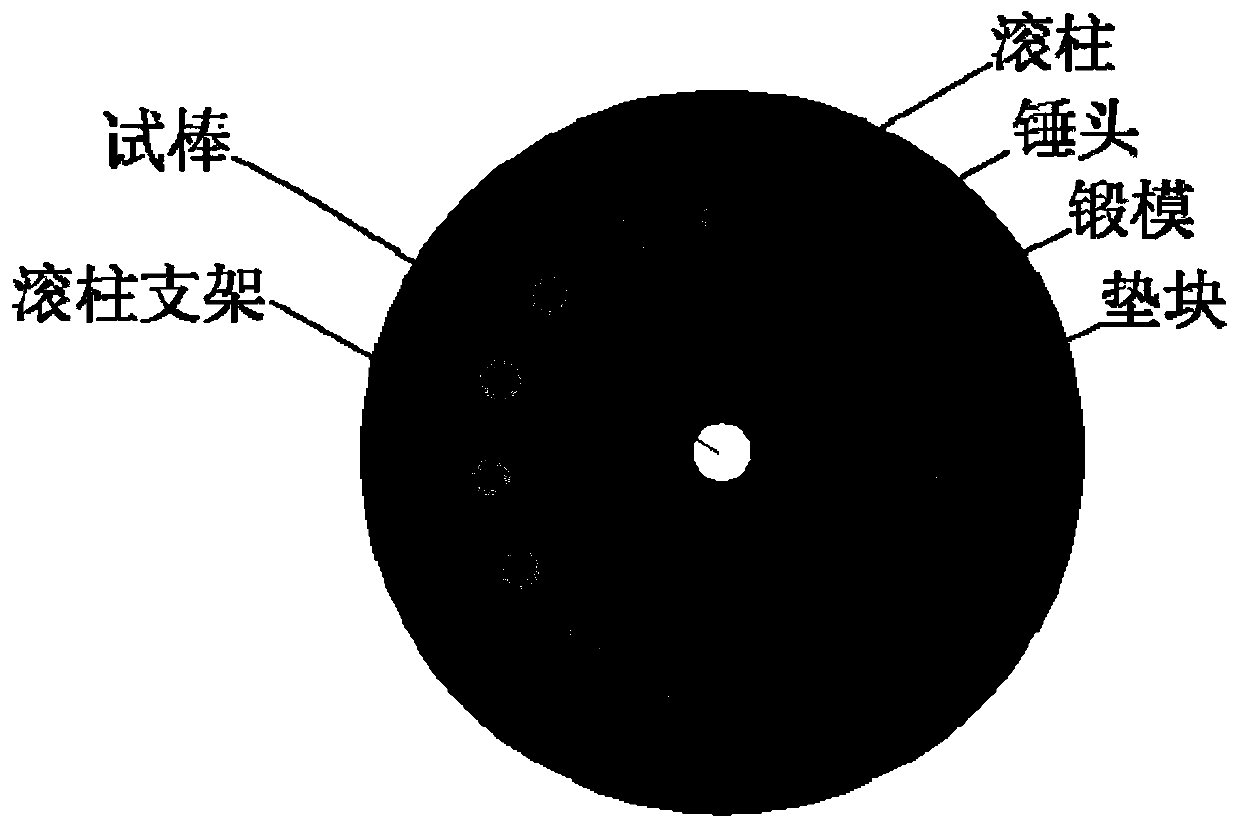

[0039] Step 3, swaging treatment:

[0040] (1) First p...

Embodiment 2

[0044] Step 1, melt purification treatment: select industrial pure aluminum AA1070 as raw material, put industrial pure aluminum in a resistance furnace and melt it to 750°C, at this time add 75ppm industrial pure titanium to the melt and perform mechanical stirring, then add 400ppm B element treatment, in which B element is added to the melt in the form of Al-3B master alloy. The melt is kept warm for 20 minutes so that the impurity elements form borides and precipitate to the bottom of the melt to realize the separation of the impurity elements from the melt. After the heat preservation is over, the industrial pure aluminum liquid is cast into copper molds of different sizes to form cast rod.

[0045] Step 2, hot extrusion deformation: put the industrial pure aluminum cast rod obtained after purification treatment in a heat treatment furnace for heat preservation. The pressed bar size is in

[0046] Step 3, swaging treatment:

[0047] (1) First place the hot-extruded ...

Embodiment 3

[0051] Step 1, melt purification treatment: select industrial pure aluminum AA1070 as raw material, put industrial pure aluminum in a resistance furnace and melt it to 780°C, at this time add 100ppm industrial pure titanium to the melt and perform mechanical stirring, then add 600ppm B element treatment, in which B element is added to the melt in the form of Al-3B master alloy. The melt is kept warm for 30 minutes so that the impurity elements form borides and precipitate to the bottom of the melt to realize the separation of the impurity elements from the melt. After the heat preservation is over, the industrial pure aluminum liquid is cast into copper molds of different sizes to form cast rod.

[0052] Step 2, hot extrusion deformation: put the industrial pure aluminum cast rod obtained after the purification treatment in a heat treatment furnace for heat preservation, the heat preservation temperature is 350°C, and the extrusion ratio is adjusted by selecting an appropria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com