Nitrogen oxide purification CHA zeolite molecular sieve as well as preparation method and application of catalyst thereof

A technology of zeolite molecular sieves and nitrogen oxides, which can be used in molecular sieve catalysts, molecular sieves and base exchange compounds, physical/chemical process catalysts, etc., and can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

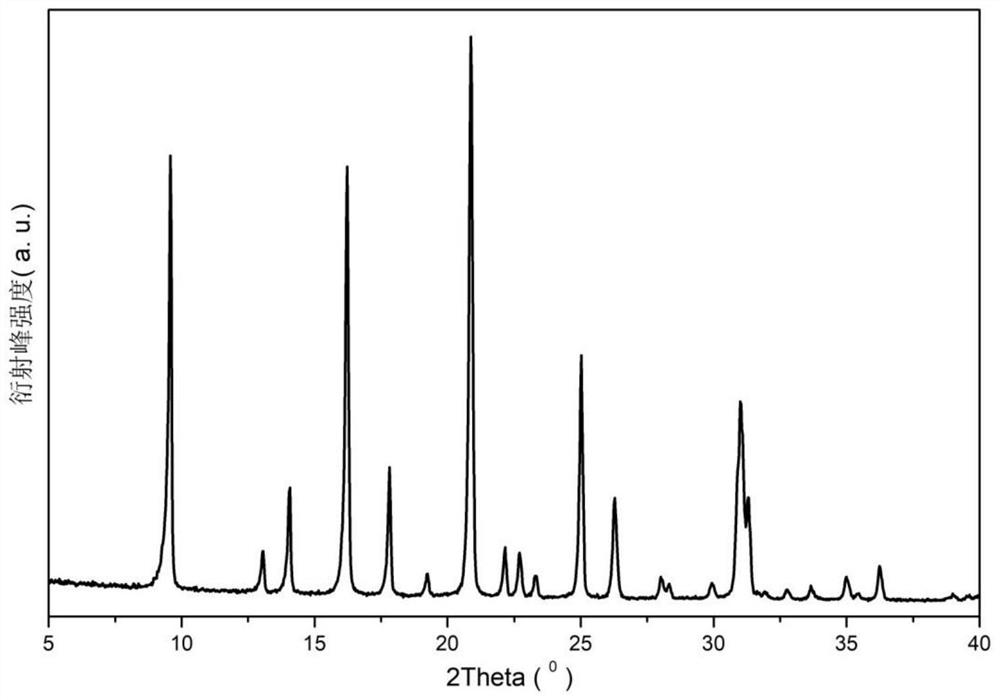

Embodiment 1

[0064] A preparation method of nitrogen oxide purification CHA zeolite SSZ-13 molecular sieve and SCR catalyst:

[0065] 1) 45.59g HY molecular sieve (silicon aluminum ratio nSiO 2 / nAl 2 o 3 =5.20, dry basis 78.1%), 53.69g NaOH sheet alkali, 69.71g deionized water after fully dissolving and dispersing, obtain the slurry component molar ratio to be nNa 2 O:nSiO 2 :nAl 2 o 3 :nH 2 O=1.5:1.0:0.192:10, aged in a crystallization kettle at 85°C for 36 hours to obtain a silica-alumina gel;

[0066] 2) Add 507.51g of silica gel solution (Na 2 O: 0.24wt%, SiO 2 : 30.36wt%), 514.44g N,N-diethyl-N'-methyl-4-quinuclidinyl ammonium hydroxide (concentration 20wt%, represented by OSDA), 21.25g NaCl and 235.61g deionized water Fully and ultrasonically stirred and mixed evenly, so that the molar ratio of the mixed slurry components nNa 2 O:nSiO 2 :nA1 2 o 3 :nOSDA:nNaCl:nH 2 O=0.12:1.0:0.0286:0.16:0.12:20; add 5% HCl solution to adjust the nOH in the system - / nSiO 2 Ratio = 0...

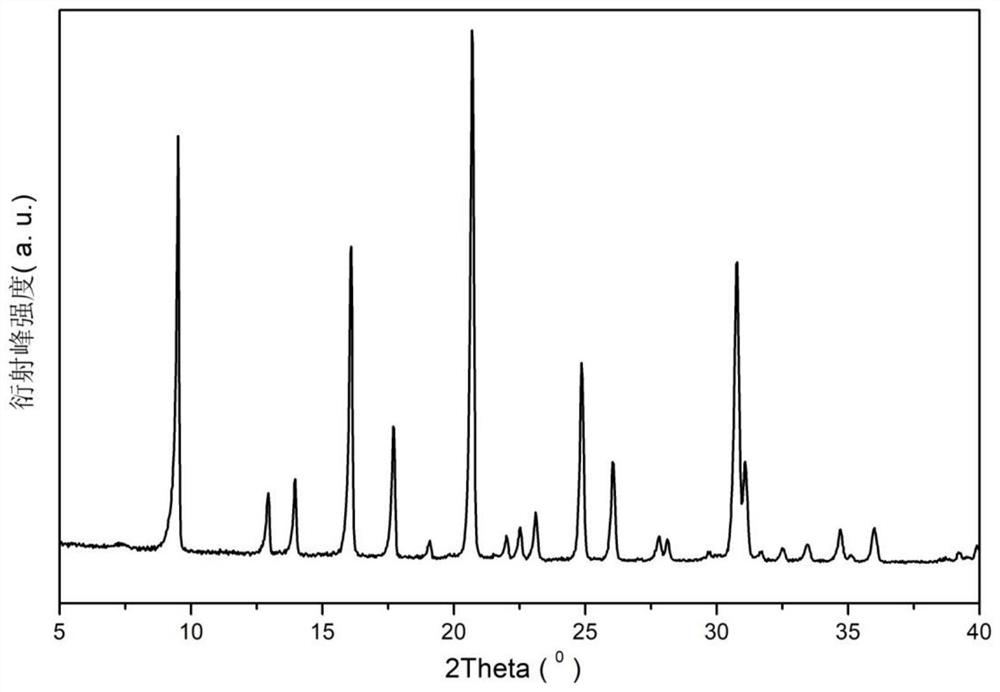

Embodiment 2

[0071] The process method of synthesizing nitrogen oxides to purify CHA zeolite SSZ-13 molecular sieve is similar to embodiment 1, and difference is the slurry component molar ratio (nNa 2 O:nSiO 2 :nAl 2 o 3 :nH 2 (0), zeolite molecular sieve type, zeolite molecular sieve silicon-alumina ratio, aging temperature and aging time, step 2) in the mixed slurry component molar ratio, silicon source type, organic template type, seed crystal addition amount, acid type, Metal salt M type, crystallization temperature and crystallization time, step 4) take H-type SSZ-13 molecular sieve 50.0g, adopt different soluble metal salt types, concentrations, solution volumes and metal loadings, and step 5) take 40.0 g copper modified CHA type SSZ-13 molecular sieve, and 20.0g silica sol (SiO 2 content: 30.0wt%) and 59.48g of deionized water were evenly mixed to make a catalyst slurry with a solid content of 38.5wt%, which was coated on the cordierite structured material by dipping method. S...

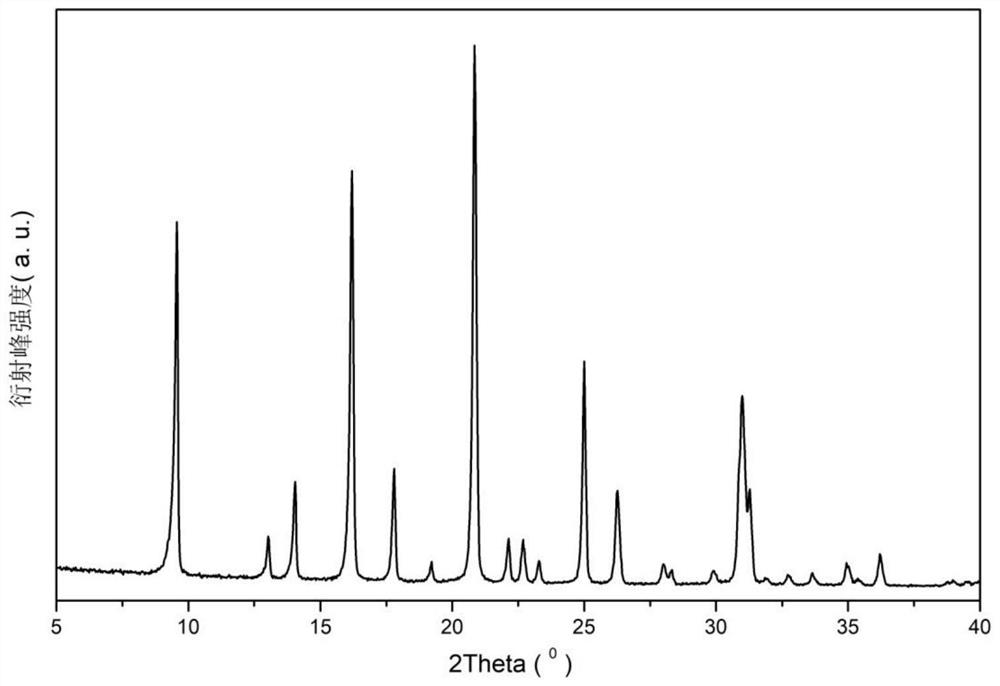

Embodiment 3

[0073]The process method of synthesizing nitrogen oxides to purify CHA zeolite SSZ-13 molecular sieve is similar to embodiment 1, and difference is the slurry component molar ratio (nNa 2 O:nSiO 2 :nAl 2 o 3 :nH 2 (0), zeolite molecular sieve type, zeolite molecular sieve silicon-alumina ratio, aging temperature and aging time, step 2) in the mixed slurry component molar ratio, silicon source type, organic template type, seed crystal addition amount, acid type, Metal salt M type, crystallization temperature and crystallization time, step 4) take 50.0g of H-type SSZ-13 molecular sieve, adopt different soluble metal salt types, concentrations, solution volumes and metal loadings, and step 5) take 40g Copper modified CHA type SSZ-13 molecular sieve, with 20.0g silica sol (SiO 2 content: 30.0wt%) and 81.54g of deionized water were evenly mixed to make a catalyst slurry with a solid content of 32.5wt%, which was coated on the cordierite structured material by dipping method. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com