CHA structure molecular sieve as well as preparation method and application of tail gas denitration catalyst of the CHA structure molecular sieve

A technology of SCR catalyst and molecular sieve, which is applied in the direction of molecular sieve catalyst, molecular sieve and base exchange compound, separation method, etc., and can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

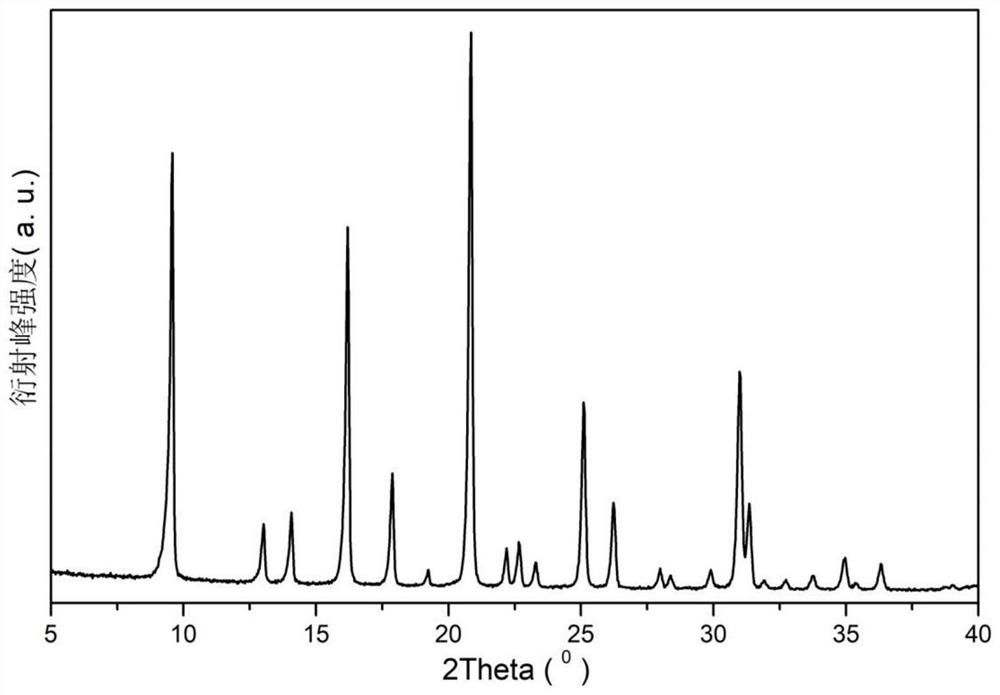

Image

Examples

Embodiment 1

[0065] A kind of preparation method of CHA type SSZ-13 molecular sieve and SCR catalyst:

[0066] 1) 45.59g HY molecular sieve (silicon aluminum ratio nSiO 2 / nAl 2 o 3 =5.20, dry basis 78.1%), 26.68g NaOH sheet alkali, 69.98g deionized water after fully dissolving and dispersing, obtain the slurry component molar ratio to be nNa 2 O:nSiO 2 :nAl 2 o 3 :nOH - :nH 2 O=0.75:1.0:0.192:1.5:10, aged in a crystallization kettle at 85°C for 36 hours to obtain a silica-alumina gel;

[0067] 2) Add 507.51g of silica gel solution (Na 2 O: 0.24wt%, SiO 2 : 30.36wt%), 239.20g N,N-diethyl-N'-methyl-(norbornan-2-yl) ammonium hydroxide (concentration 20wt%, represented by OSDA), 56.31g NaOH caustic soda, 21.25g NaCl and 184.97g deionized water are fully mixed with ultrasonic stirring, so that the molar ratio of the mixed slurry components is nNa 2 O:nSiO 2 :nA1 2 o 3 :nOSDA:nNaCl:nH 2 O=0.35:1.0:0.0286:0.08:0.12:15; add 5% HCl solution to adjust nOH in the system - / nSiO 2 Ra...

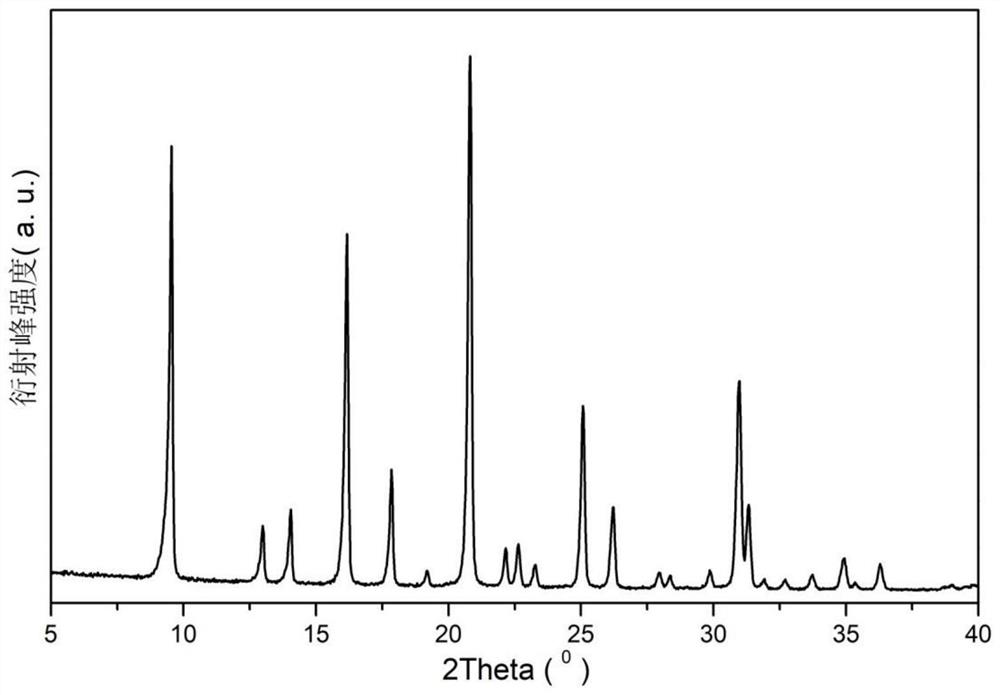

Embodiment 2

[0072] The process method of synthesizing CHA type SSZ-13 molecular sieve is similar to embodiment 1, and difference is the slurry component molar ratio (nNa 2 O:nSiO 2 :nAl 2 o 3 :nH 2 (0), zeolite molecular sieve type, zeolite molecular sieve silicon-alumina ratio, aging temperature and aging time, step 2) in the mixed slurry component molar ratio, organic template type, type of silicon source, seed crystal addition amount, acid type added , metal salt M type, crystallization temperature and crystallization time, step 4) get H-type SSZ-13 molecular sieve 50.0g, adopt different soluble metal salt types, concentrations, solution volumes and metal loads, and step 5) take 40.0g copper modified CHA type SSZ-13 molecular sieve, and 20.0g silica sol (SiO 2 content: 30.0wt%) and 59.48g of deionized water were evenly mixed to make a catalyst slurry with a solid content of 38.5wt%, which was coated on the cordierite structured material by dipping method. Specific parameters in th...

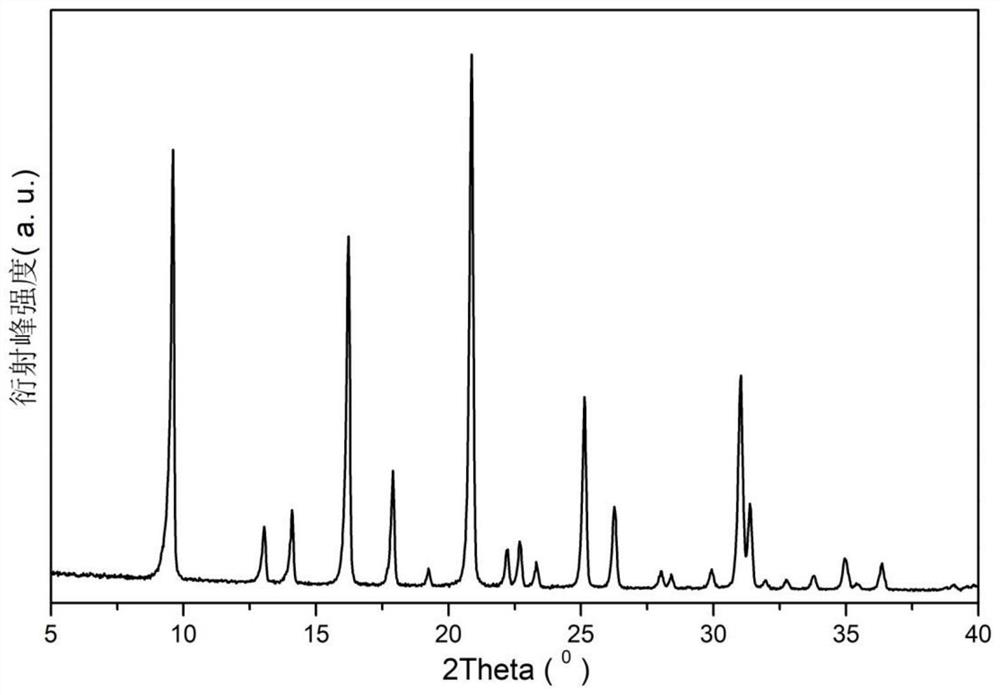

Embodiment 3

[0074] The process method of synthesizing CHA type SSZ-13 molecular sieve is similar to embodiment 1, and difference is the slurry component molar ratio (nNa 2 O:nSiO 2 :nAl 2 o 3 :nH 2(0), zeolite molecular sieve type, zeolite molecular sieve silicon-alumina ratio, aging temperature and aging time, step 2) in the mixed slurry component molar ratio, organic template type, type of silicon source, seed crystal addition amount, acid type added , metal salt M type, crystallization temperature and crystallization time, step 4) get H-type SSZ-13 molecular sieve 50.0g, adopt different soluble metal salt types, concentrations, solution volumes and metal loads, and step 5) take 40g copper modified CHA type SSZ-13 molecular sieve, and 20.0g silica sol (SiO 2 content: 30.0wt%) and 95.93g of deionized water were evenly mixed to make a catalyst slurry with a solid content of 29.5wt%, which was coated on the cordierite structured material by dipping method. Specific parameters in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com