Preparation method of multi-grain-scale lamellar structure aluminum alloy

An aluminum alloy, strengthening layer technology, applied in mechanical equipment, heat exchange equipment, rotors, etc., can solve the problems of difficult to control interface oxidation, complex process, single mixed crystal material components, etc., to achieve large microstructure design directivity and The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

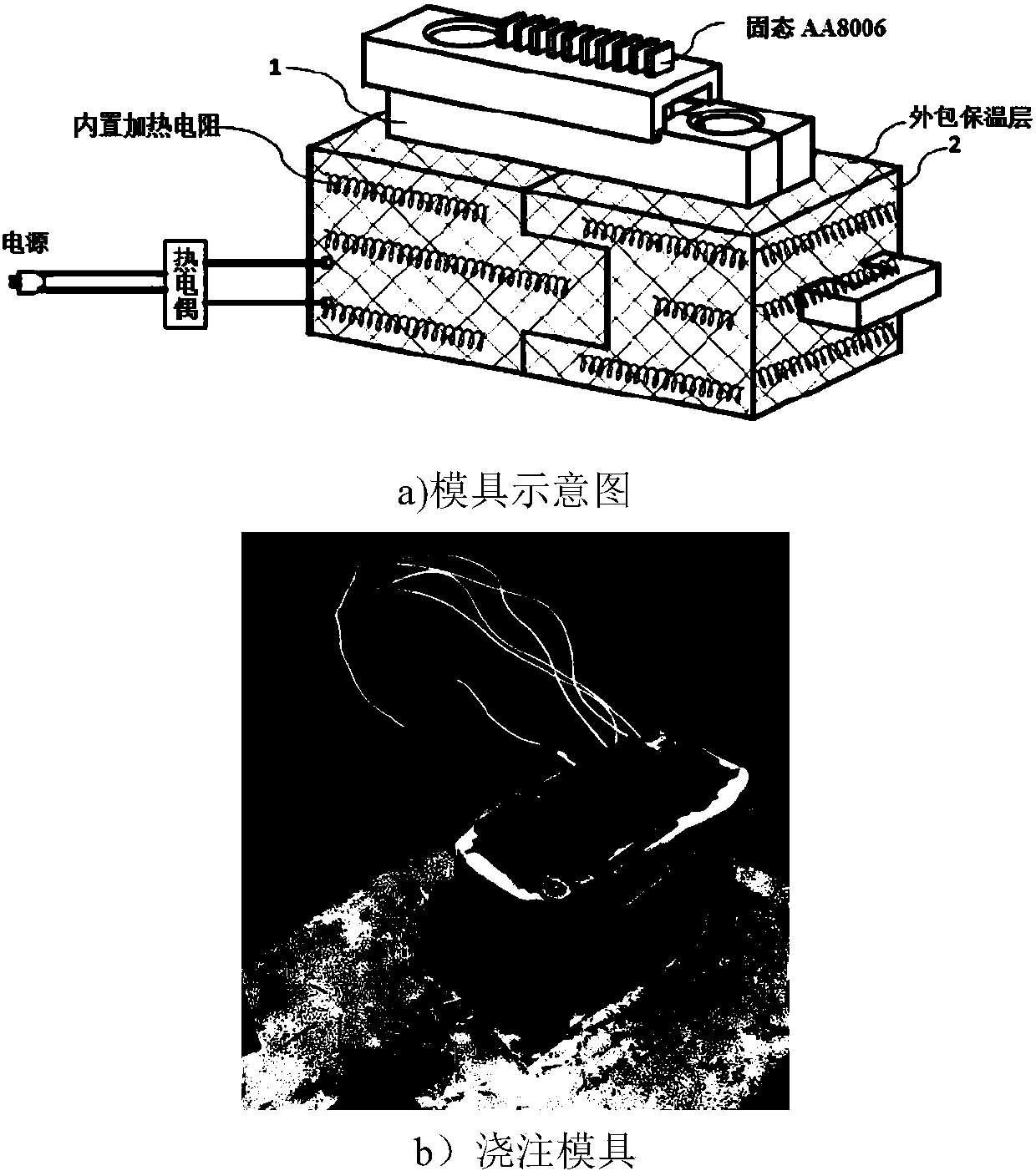

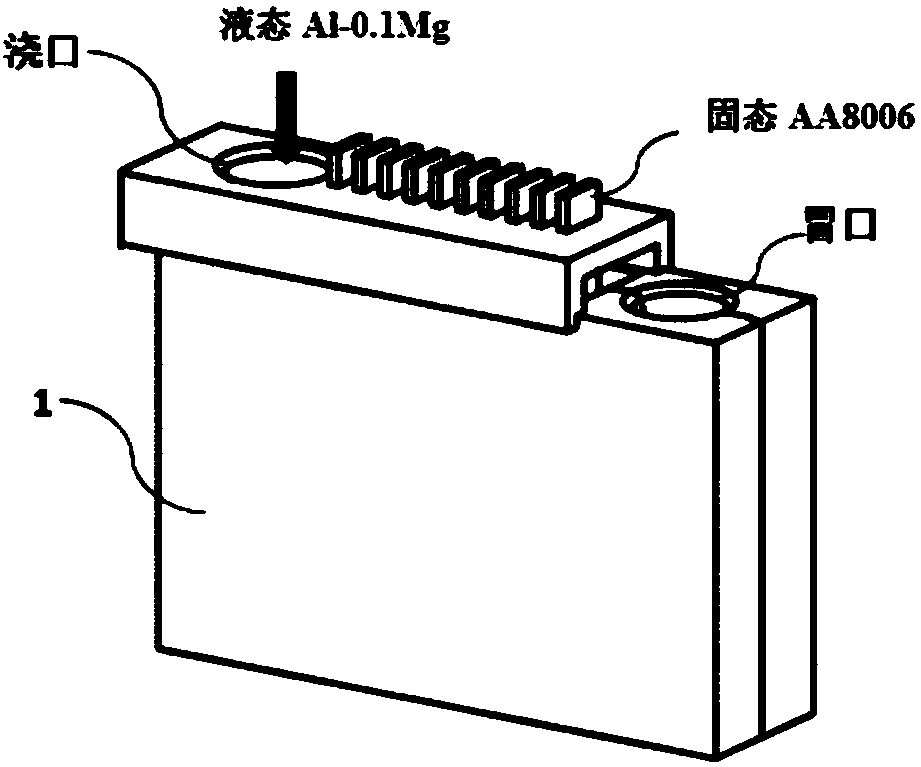

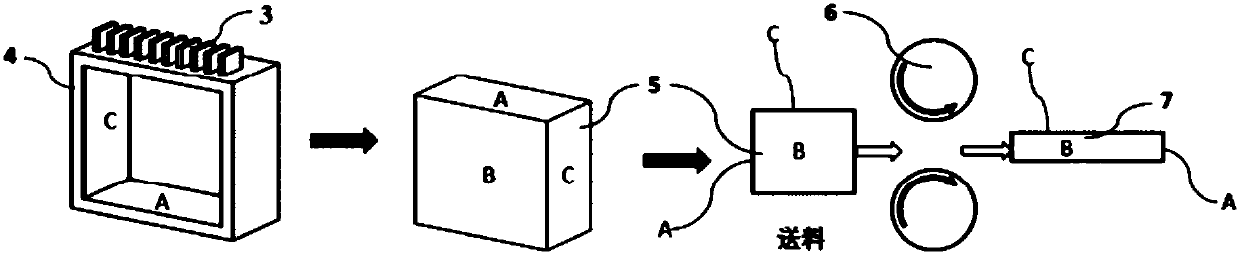

[0021] Such as Figure 1-5 As shown, taking solid AA8006 aluminum alloy and liquid Al-0.1Mg aluminum alloy as examples, detailed implementation and specific operations are given. The following examples involve three steps including: pretreatment, casting, plastic deformation, multi-grain scale, where:

[0022] Such as figure 1 As shown, the surface of the solid AA8006 aluminum alloy is chemically cleaned to remove oil and oxides on the surface, and then the surface is galvanized. The galvanized layer is electroplated, and the thickness of the zinc layer is 30 μm. The processed solid pure aluminum is preset in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com