Multi-extrusion device for preparing layered isomeric magnesium alloy and method for preparing layered isomeric magnesium alloy by utilizing device

An extrusion device and magnesium alloy technology, which is applied in the field of multiple extrusion devices for preparing layered heterogeneous magnesium alloys, can solve the problems of poor room temperature plastic deformation ability, limit large-scale application, and reduce material toughness, and achieve low cost , easy mechanized production and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

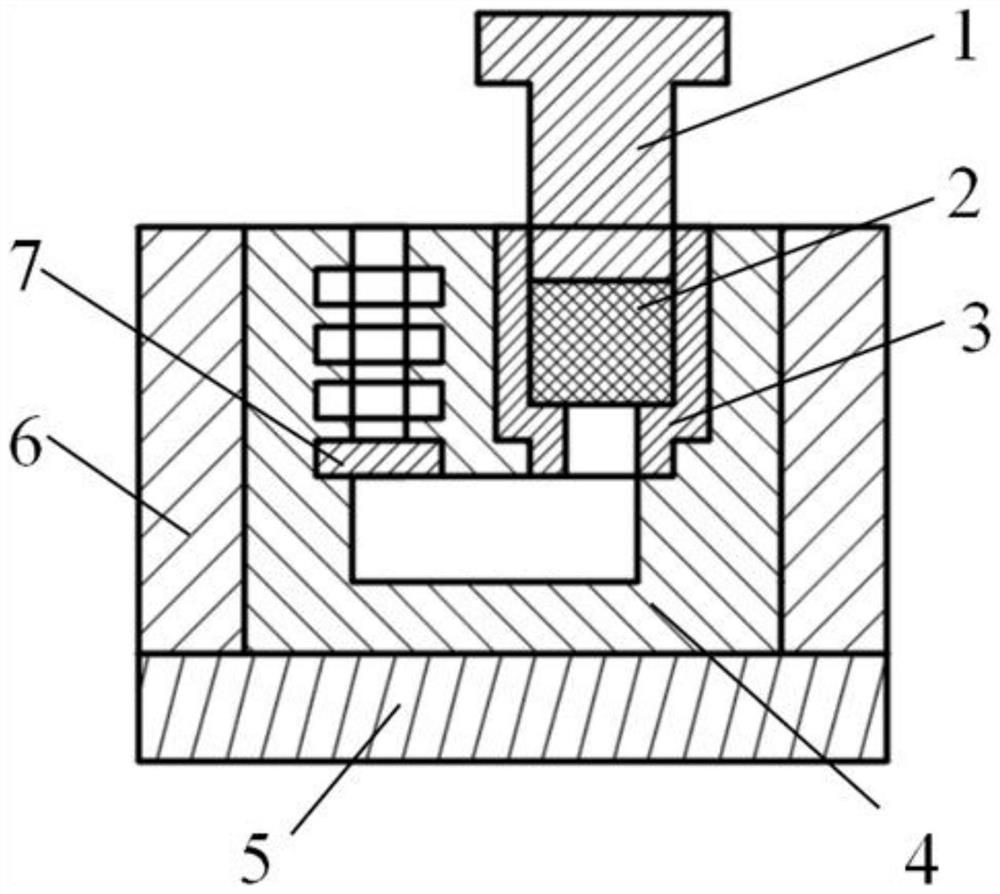

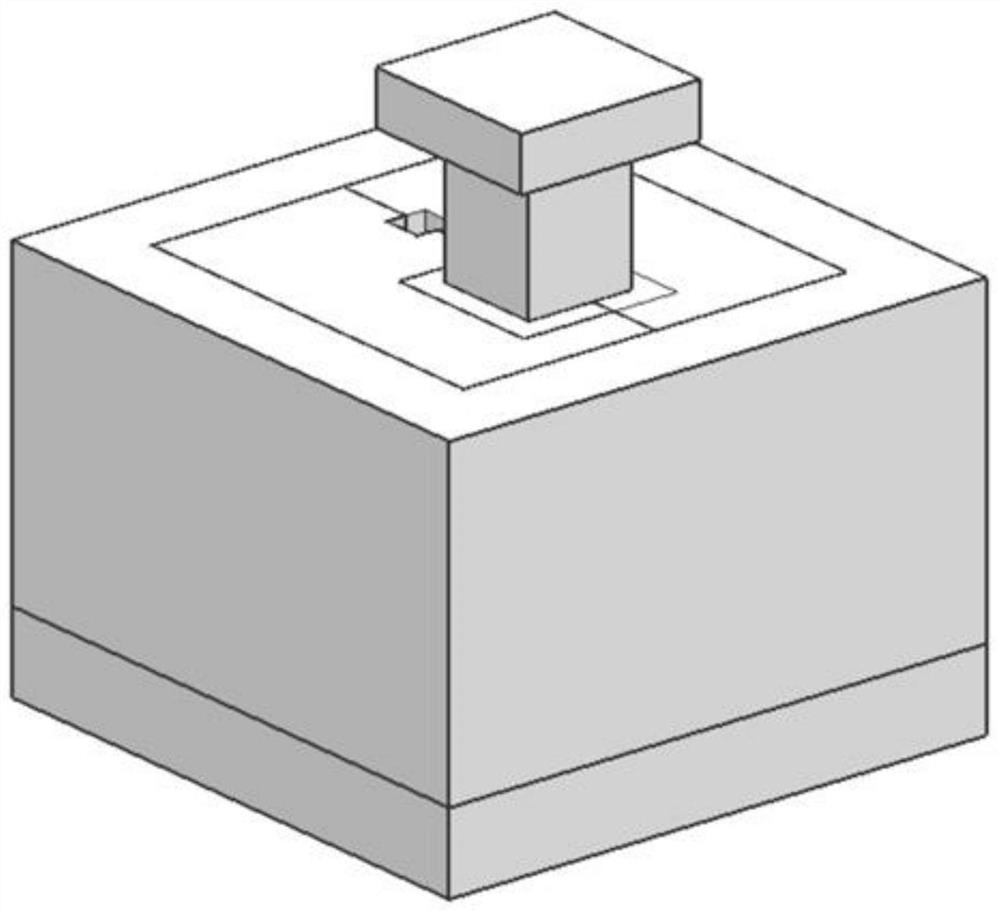

[0038] In the following, the present invention will be further described in detail in conjunction with the embodiments. This embodiment adopts the device and method of the present invention, and provides detailed implementation methods and operating procedures.

[0039] (1). The atomic composition percentage of the magnesium alloy is Mg-2Zn-0.5Ca-4Sn, and the alloy is homogenized at a temperature of 480°C for 8 hours;

[0040] (2). From the as-cast magnesium alloy ingot, cut out a large blank with a length of 120mm, a width of 120mm, and a height of 135mm and a number of small blanks with a length of 120mm, a width of 120mm, and a height of 34mm. Grinding to remove scale;

[0041] (3). Put the mold and blank into the heating furnace for preheating, the temperature is 350°C;

[0042] (4). Install an insert with an extrusion ratio of 4 and put a large billet into the mold. The billet is pressed into the cavity by the force exerted by the punch, and the extrusion punch continues...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com