A preparation method of multi-scale precipitation heterogeneous layered structure aluminum alloy

An aluminum alloy, multi-scale technology, applied in the direction of heat exchange equipment, stators, transmissions, etc., can solve the problems of small sample size, poor heat resistance, high requirements for equipment and molds, and achieve the effect of controllable layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

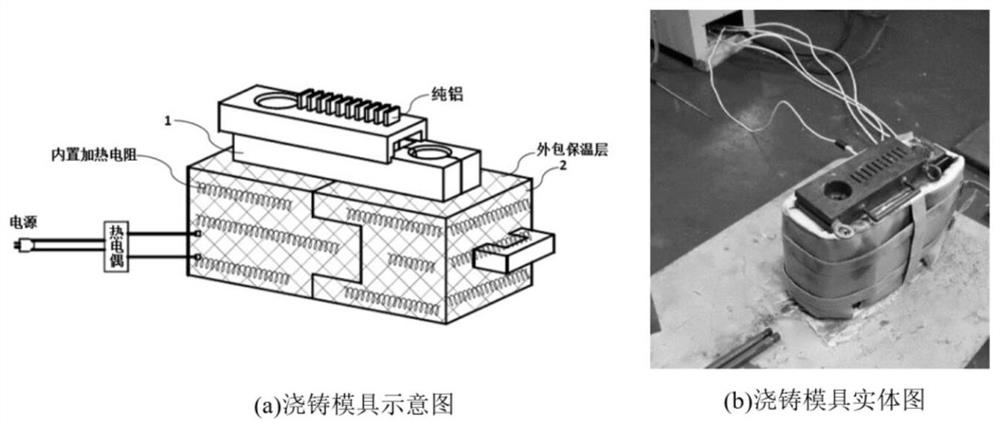

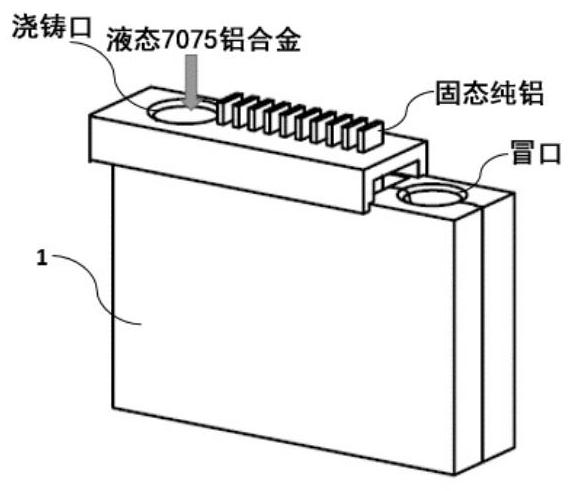

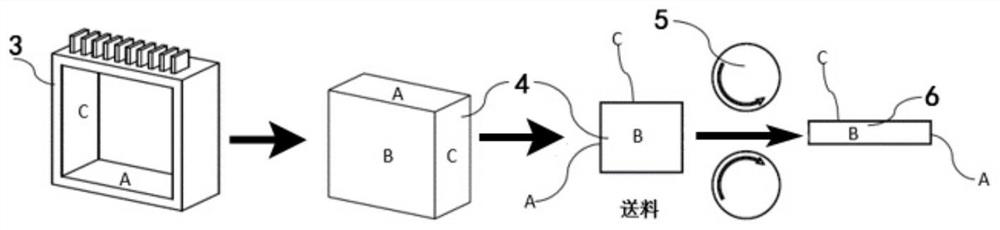

[0022] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. Such as Figure 1~4 As shown, according to the melting points of various aluminum alloys, industrial pure aluminum with a higher melting point is selected as the solid material, and 7075 aluminum alloy with a lower melting point is used as the liquid material. The specific operation involves the following three steps: pretreatment, casting, multi-scale precipitation, in:

[0023] (1) Pretreatment: such as figure 1 As shown, the surface of the solid pure aluminum sheet is chemically cleaned to remove oil and oxides on the surface, and then the surface is galvanized. The galvanized layer is electroplated, and the thickness of the zinc layer is 30 μm. The treated pure aluminum is preset in the cavity of the mold 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com