Chopped carbon fiber toughened silicon carbide composite material and preparation method thereof

A technology of chopped carbon fiber and tough silicon carbide, which is applied in the field of fiber toughened composite materials, can solve the problems of low solid content, significant anisotropy of hot pressing and sintering, and the inability to realize the preparation of large-sized parts, and achieve tribological and other properties Excellent effects in high performance, tribology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

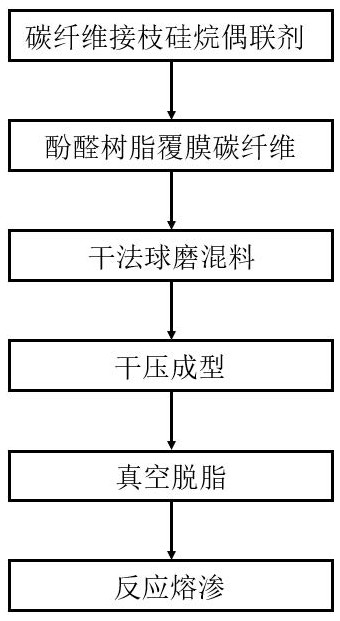

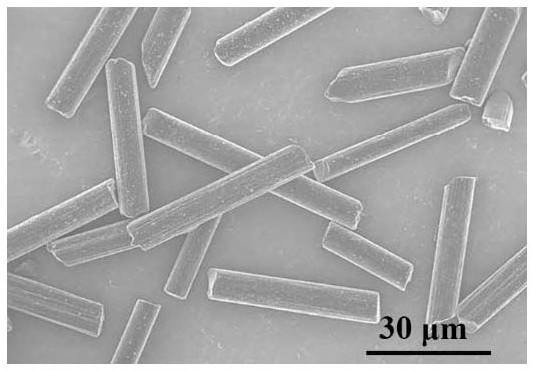

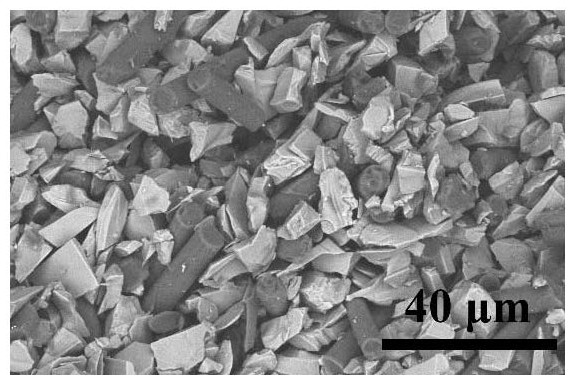

[0037] The invention relates to a chopped carbon fiber toughened silicon carbide (C f / SiC) composite materials. The C f / SiC composites consist of a homogeneously dispersed chopped carbon fiber reinforcement and a silicon carbide matrix. Chopped carbon fiber and silicon carbide coated with high carbon residual rate binder are used as raw materials, mixed by dry ball milling, dry pressing, vacuum degreasing (700-1100 °C, 0.5-2h), vacuum reaction infiltration (1450 °C) ~1650℃, 0.5~2h) and other processes to prepare the above C f / SiC composites. The length of the chopped carbon fiber is 10-130 μm, the diameter is 6-8 μm, and the particle size of the silicon carbide powder is 0.5-50 μm. The high carbon residual rate binder may be phenolic resin, and the chopped carbon fibers coated with the high carbon residual rate binder may be chopped carbon fibers coated with phenolic resin. Wherein, the content of phenolic resin in the total volume of the chopped carbon fiber covered w...

Embodiment 1

[0051] This embodiment provides a C f / SiC composite material preparation method, the C f / SiC composite material is obtained by dry pressing forming-reaction infiltration method with phenolic resin-coated chopped carbon fiber, silicon carbide powder, and high-purity silicon powder as raw materials.

[0052] Include the following steps:

[0053] (1) Carbon fiber grafted silane coupling agent: chopped carbon fiber (50g), aminopropyltriethoxysilane (KH550) (0.5g), absolute ethanol (70mL), deionized water (30mL) in 60 React at ℃ for 2 hours to obtain chopped carbon fibers grafted by coupling agent, wherein the content of KH550 is 1 wt% of the carbon fibers. The chopped carbon fiber has a length of 10 to 130 μm and a diameter of 6 μm.

[0054](2) Phenolic resin coated chopped carbon fiber: the ethanol solution of the chopped carbon fiber grafted by the coupling agent of 50g and 50mL phenolic resin (the content of phenolic resin accounts for 25vol of the composite powder of the ...

Embodiment 2

[0060] This embodiment provides a C f / SiC composite material preparation method, the C f / SiC composite material is obtained by dry pressing forming-reaction infiltration method with phenolic resin-coated chopped carbon fiber, silicon carbide powder, and high-purity silicon powder as raw materials.

[0061] Include the following steps:

[0062] (1) Carbon fiber grafted silane coupling agent: chopped carbon fiber (50g), aminopropyltriethoxysilane (KH550) (3g), absolute ethanol (70mL), deionized water (30mL) at 70 ° C The reaction was carried out for 2.5 hours to obtain chopped carbon fibers grafted by the coupling agent, wherein the content of KH550 was 6 wt% of the carbon fibers. The chopped carbon fiber has a length of 10 to 130 μm and a diameter of 7 μm.

[0063] (2) Phenolic resin coated chopped carbon fiber: 50mL ethanol solution of the chopped carbon fiber grafted with 50g described coupling agent and phenolic resin (the content of phenolic resin is 1% of the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com