Annular conveying mechanism for assembling cylindrical lithium ion battery cap assembly

A technology of lithium-ion battery and circular transportation, which is applied in the direction of battery pack parts, battery cover/end cover, electrical components, etc. It can solve the problems of low efficiency, easy deviation, time-consuming and labor-intensive manual transmission, etc., and achieve good compatibility and Coordination, stable and reliable positioning force, and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

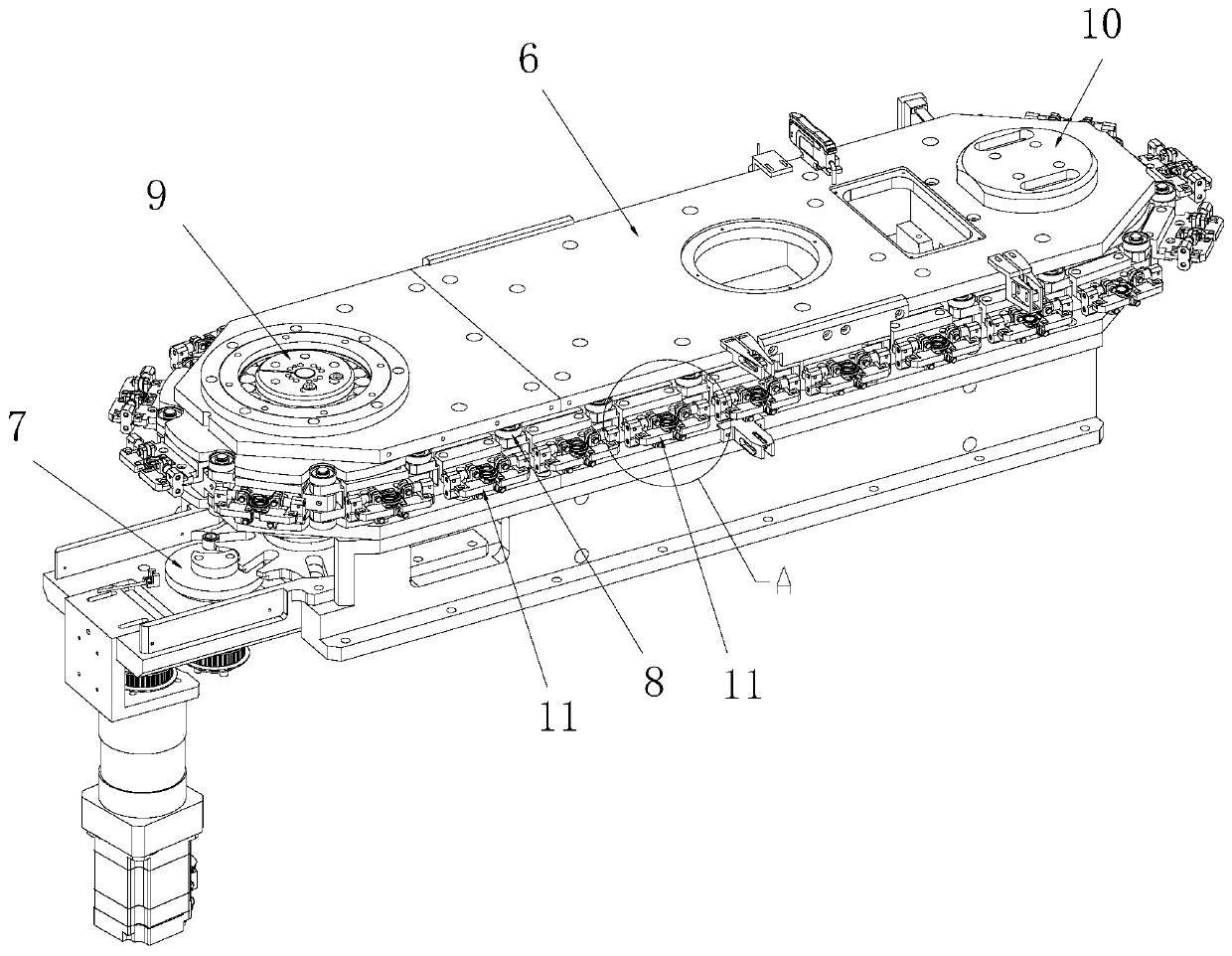

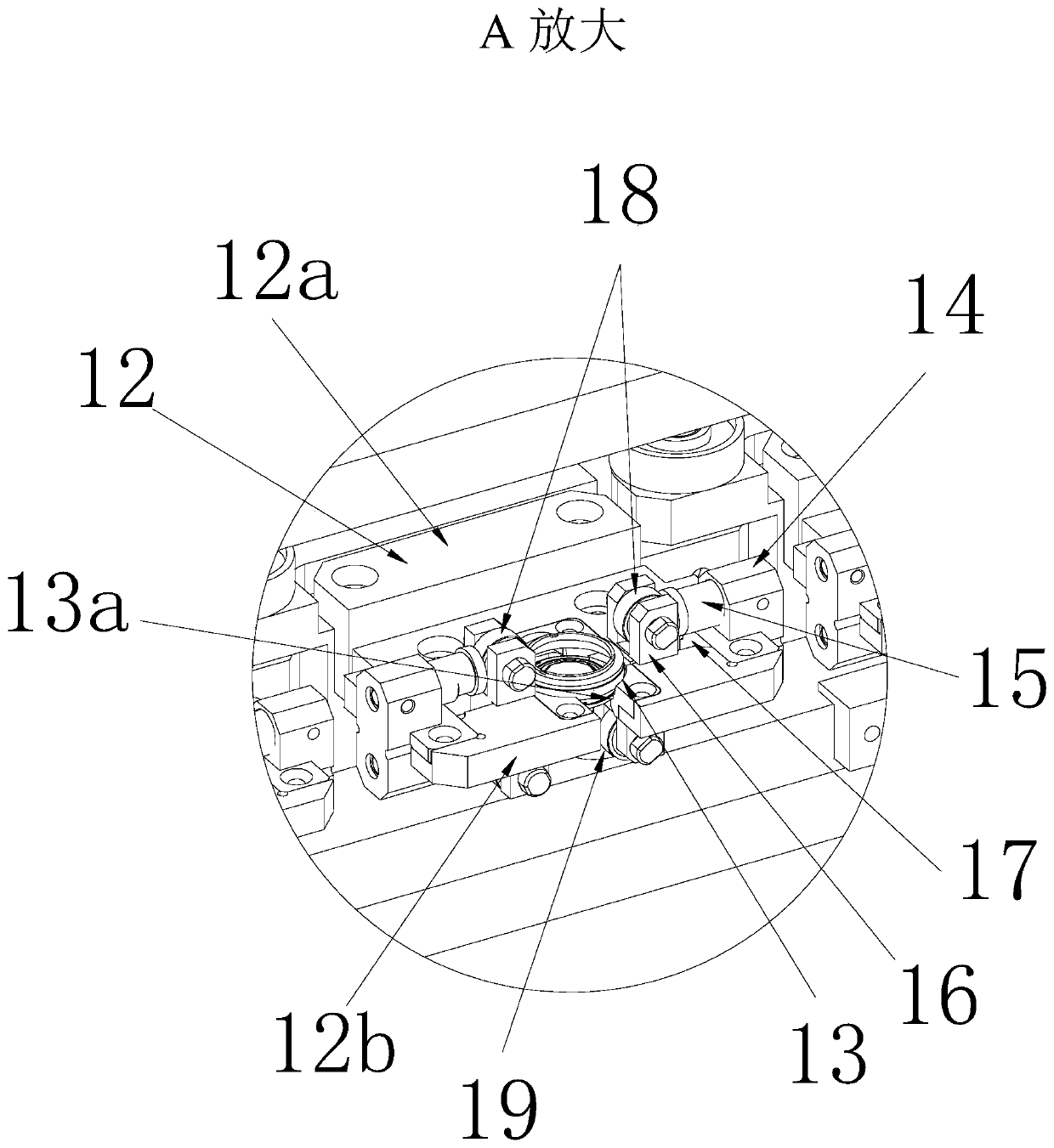

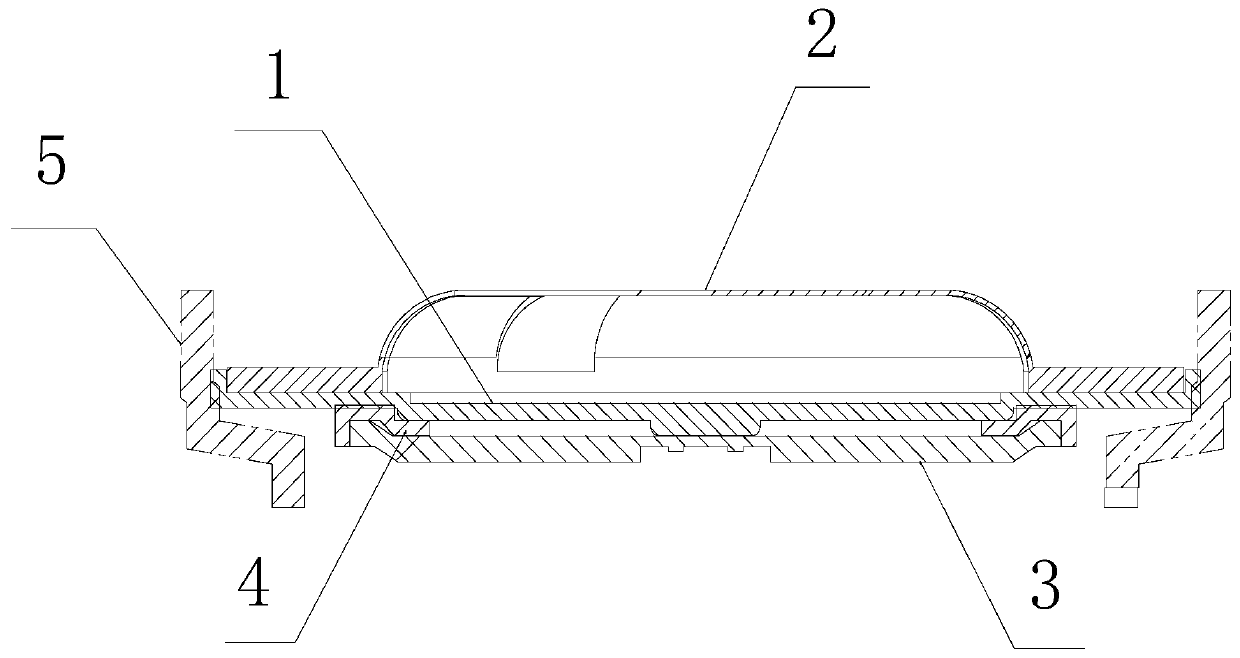

[0026] Example: Combine figure 1 with figure 2 As shown, it is a specific embodiment of the annular conveying mechanism for the assembly of the cylindrical lithium-ion battery cap assembly of the present invention, which is specially used for conveying such as image 3 Components of the cylindrical Li-ion battery cap shown.

[0027] This mechanism has machine platform 6, and machine platform 6 is provided with servomotor index plate 7, transmission sprocket group and the annular transmission chain 8 that is tensioned by transmission chain wheel group, and transmission chain wheel group is arranged on machine platform 6 The driving sprocket 9, the driven sprocket 10 and some tensioning sprockets (not visible in the figure), the servo motor indexing plate 7 is connected with the driving sprocket 9. Such as figure 1 As shown, the transmission chain 8 in this embodiment is arranged in an oval shape. At the same time, another core design of the present invention is that a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com