Method for preparing (Z)-istradefylline

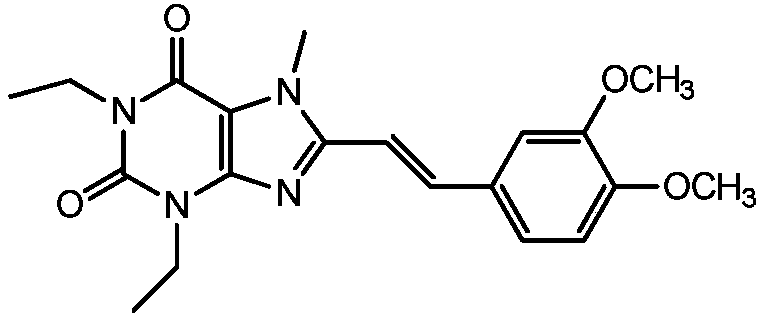

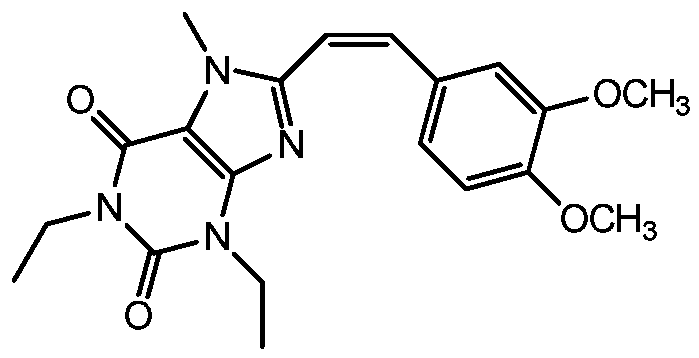

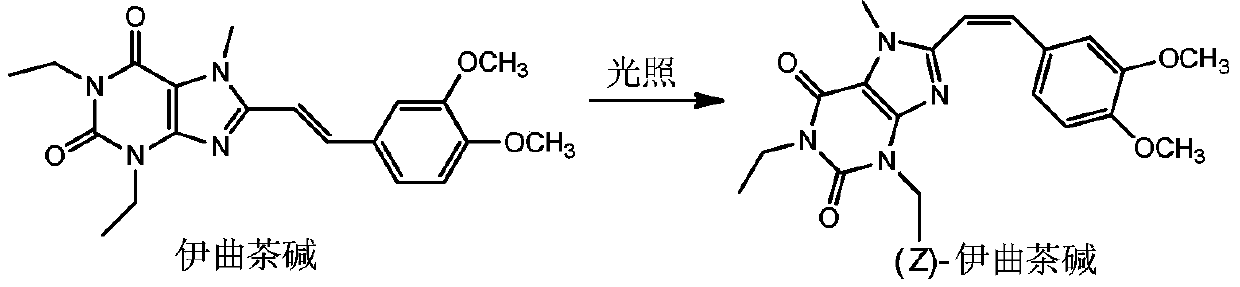

A technology of istradefylline and acetonitrile, applied in the field of medicinal chemistry, can solve the problems of cumbersome operation, waste of materials, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 100 mg of istradefylline into a test tube, and add 20 ml of solvent (acetonitrile-water=4:1 (volume ratio)). Close the lid tightly, shake to dissolve, and place under sunlight for 1 to 1.5 hours;

[0030] (2) Separation and preparation are carried out by reverse high performance liquid chromatography preparation method, and the elution fraction of (Z)-istradefylline is collected;

[0031] The conditions of the reverse high performance liquid chromatography preparative method are:

[0032] Sample: solution after light treatment

[0033] Chromatographic column: Hanbang Dubhe C18, Φ30×250mm, 10um

[0034] Detection wavelength: 355nm

[0035] Mobile phase: acetonitrile-water=70:30 (volume ratio)

[0036] Flow rate: 30ml / min

[0037] Injection volume: 5ml;

[0038] (3) The collected solution was evaporated to remove acetonitrile under reduced pressure at 30-35°C, transferred to a petri dish, put into a lyophilizer and freeze-dried according to the procedure t...

Embodiment 2

[0040] (1) Weigh 100 mg of istradefylline into a test tube, and add 20 ml of solvent (acetonitrile-water=3:1 (volume ratio)). Close the lid tightly, shake to dissolve, and place under sunlight for 1 to 1.5 hours;

[0041] (2) Separation and preparation are carried out by reverse-phase high-performance liquid chromatography preparation method, and the elution fraction of (Z)-istradefylline is collected; the conditions of the reverse-phase high-performance liquid chromatography preparation method are the same as in Example 1;

[0042] (3) The collected liquid was evaporated to remove acetonitrile under reduced pressure at 25-30°C, transferred to a petri dish, put into a lyophilizer and freeze-dried according to the procedure to obtain 63 mg of the target substance, HPLC: 99.5% (area normalization method) .

Embodiment 3

[0044] (1) Weigh 100 mg of istradefylline into a test tube, and add 20 ml of solvent (acetonitrile-water=2:1 (volume ratio)). Close the lid tightly, shake to dissolve, and place under sunlight for 1 to 1.5 hours;

[0045] (2) Separation and preparation are carried out by reverse-phase high-performance liquid chromatography preparation method, and the elution fraction of (Z)-istradefylline is collected; the conditions of the reverse-phase high-performance liquid chromatography preparation method are the same as in Example 1;

[0046] (3) The collected liquid was evaporated to remove acetonitrile under reduced pressure at 28-32°C, transferred to a petri dish, put into a lyophilizer and freeze-dried according to the procedure to obtain 59 mg of the target substance, HPLC: 99.0% (area normalization method) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com