Pile foundation detection system using self-balancing method

A detection system and self-balancing technology, applied in the direction of infrastructure engineering, infrastructure testing, construction, etc., to achieve the effect of strengthening connection strength, increasing bearing capacity, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the drawings.

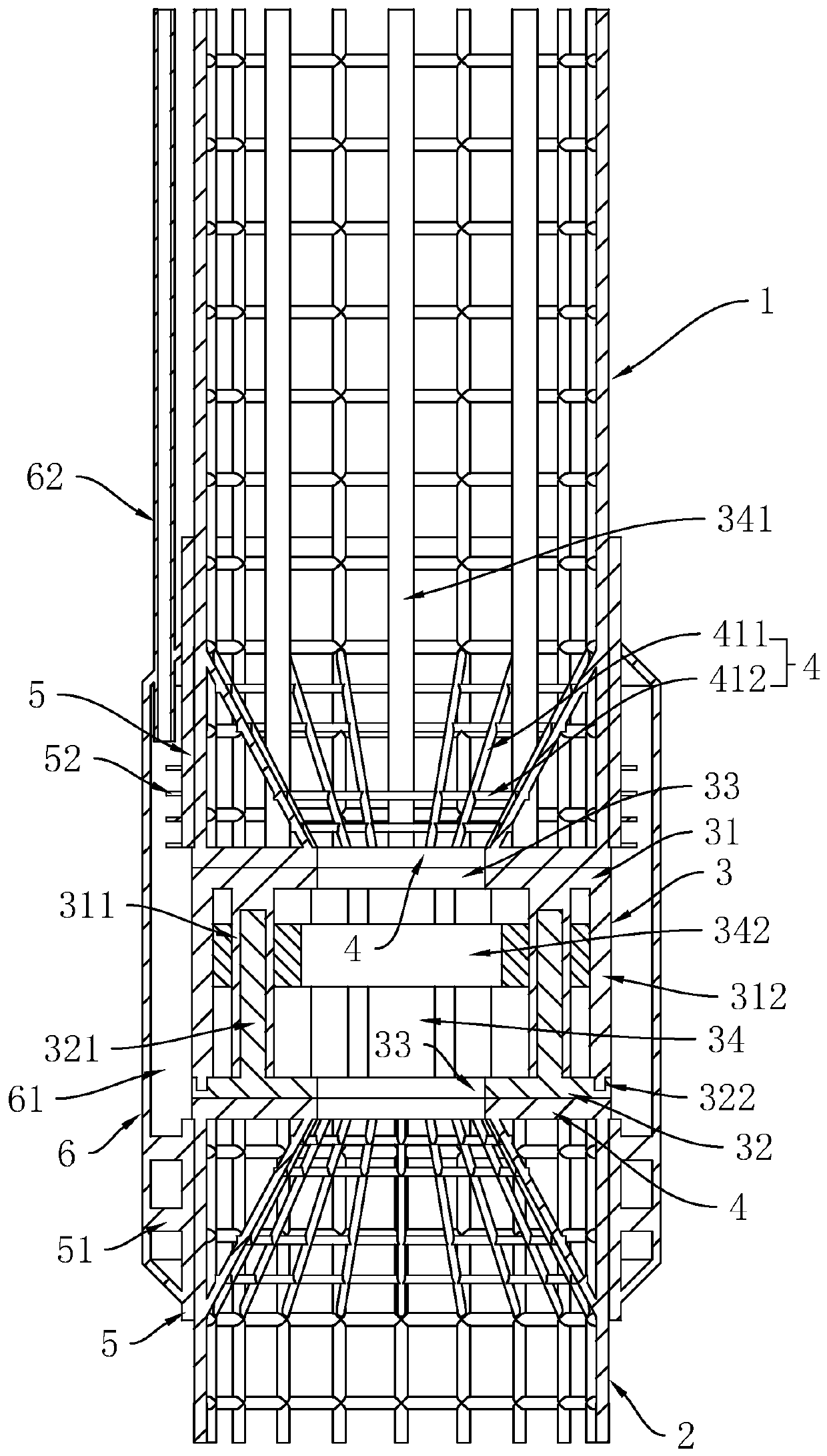

[0032] Reference figure 1 , Is a self-balanced pile foundation detection system disclosed in the present invention, which includes an upper steel cage 1, a lower steel cage 2 and a load box 3, and the load box 3 is placed between the upper steel cage 1 and the lower steel cage 2.

[0033] The ends of the upper steel cage 1 and the lower steel cage 2 close to each other are fixedly connected with a connecting ring 4, and the ends of the upper steel tight cage and the lower steel cage 2 close to each other are also welded with horn ribs 41. Close to and weld to the corresponding connecting ring 4 respectively. The horn rib 41 includes a plurality of upper ends fixed to the circumferential surface of the upper reinforcement cage 1 or the lower reinforcement cage 2 and the lower ends are inclined toward the middle of the connecting ring 4 and fixed to the diagonal steel bars 411 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com