Construction method of fabricated building

A building construction and assembly technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as insufficient building stability, achieve good environmental protection benefits, reduce sewage discharge and construction waste, and improve on-site construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

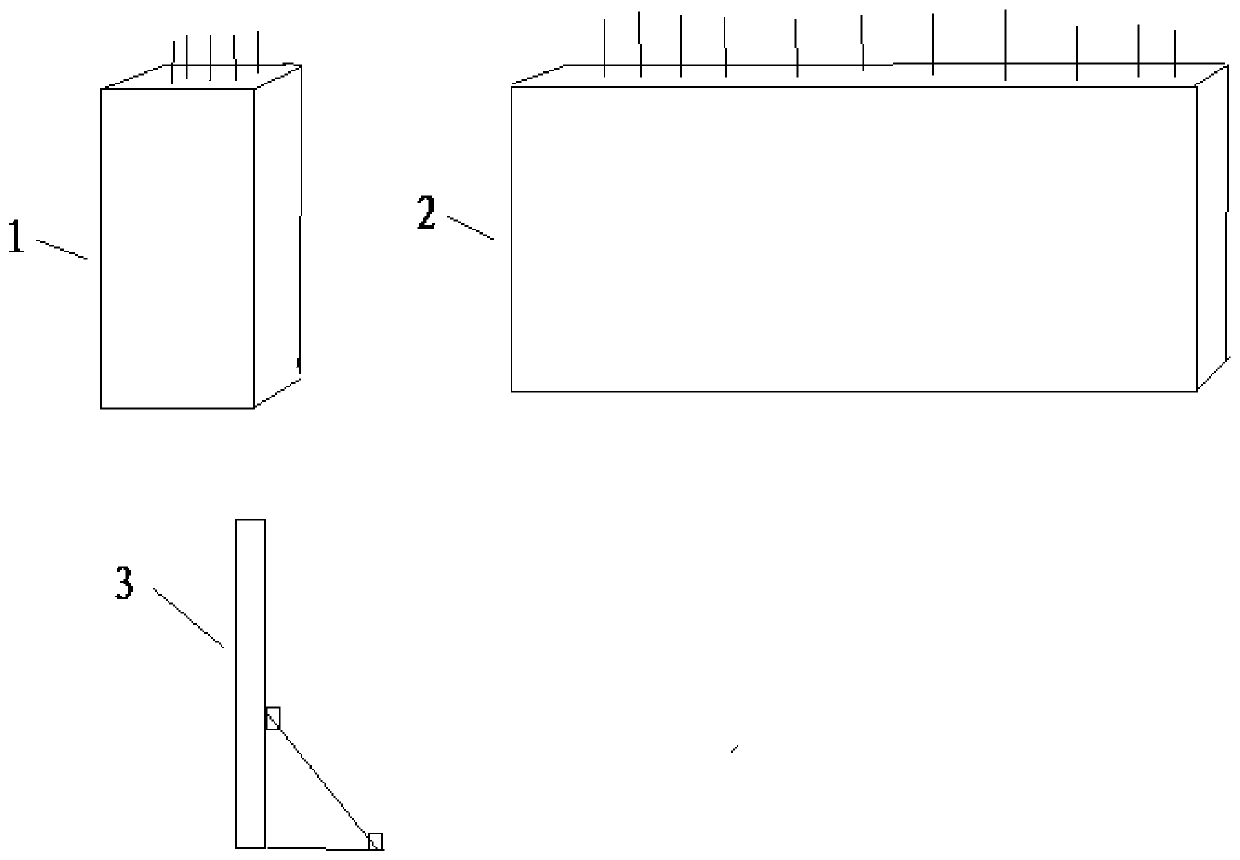

[0023] S01: Binding the load-bearing structural steel bars and the vertical main bars of the wall-column structure, the load-bearing structural steel bars and the vertical main bars of the wall-column structure are arranged to cross each other; figure 1 As shown in 1 and 2, it is the vertical structure after cast-in-place molding;

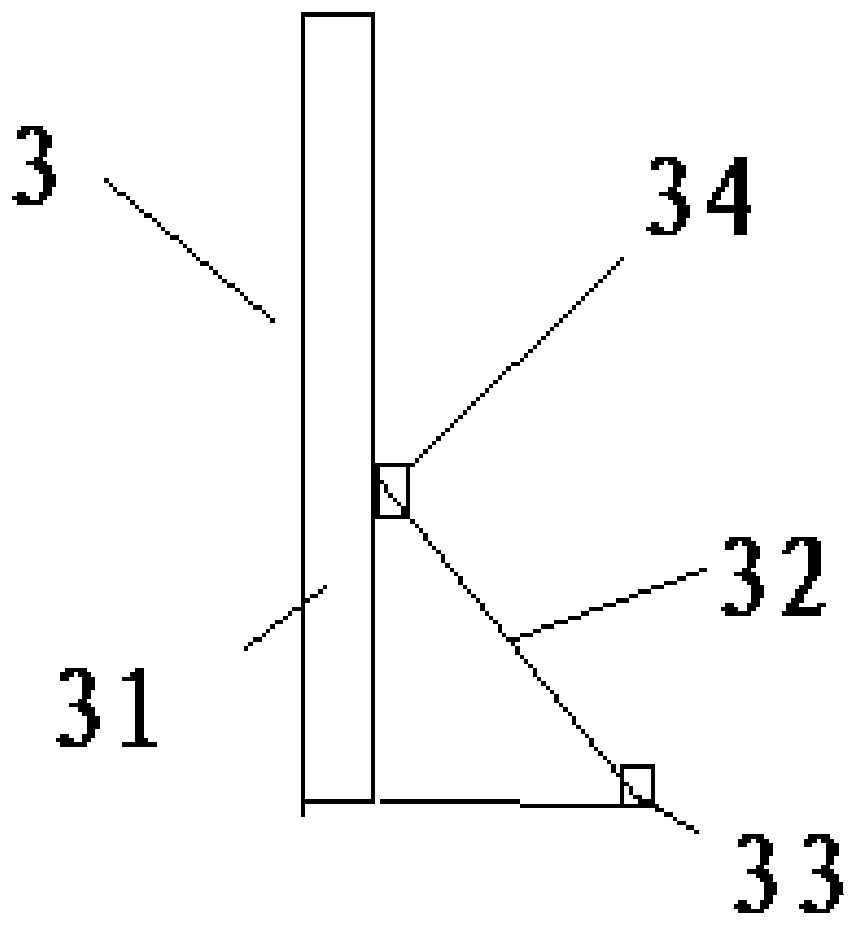

[0024] S02: Assemble the wall bearing plate, the column bearing plate 3 and other vertical formwork, so that the wall bearing plate, the column bearing plate and other vertical formwork are arranged at intervals perpendicular to the horizontal plane to form a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com