Conical draft tube provided with oval and regular hexagon grid

A regular hexagon, draft tube technology, used in hydropower, engine components, machines/engines, etc., can solve the problems of vortex belt offset, crushing pressure, pulsation in the draft tube, and reduce vortex energy and fluid separation. And the effect of small shedding and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

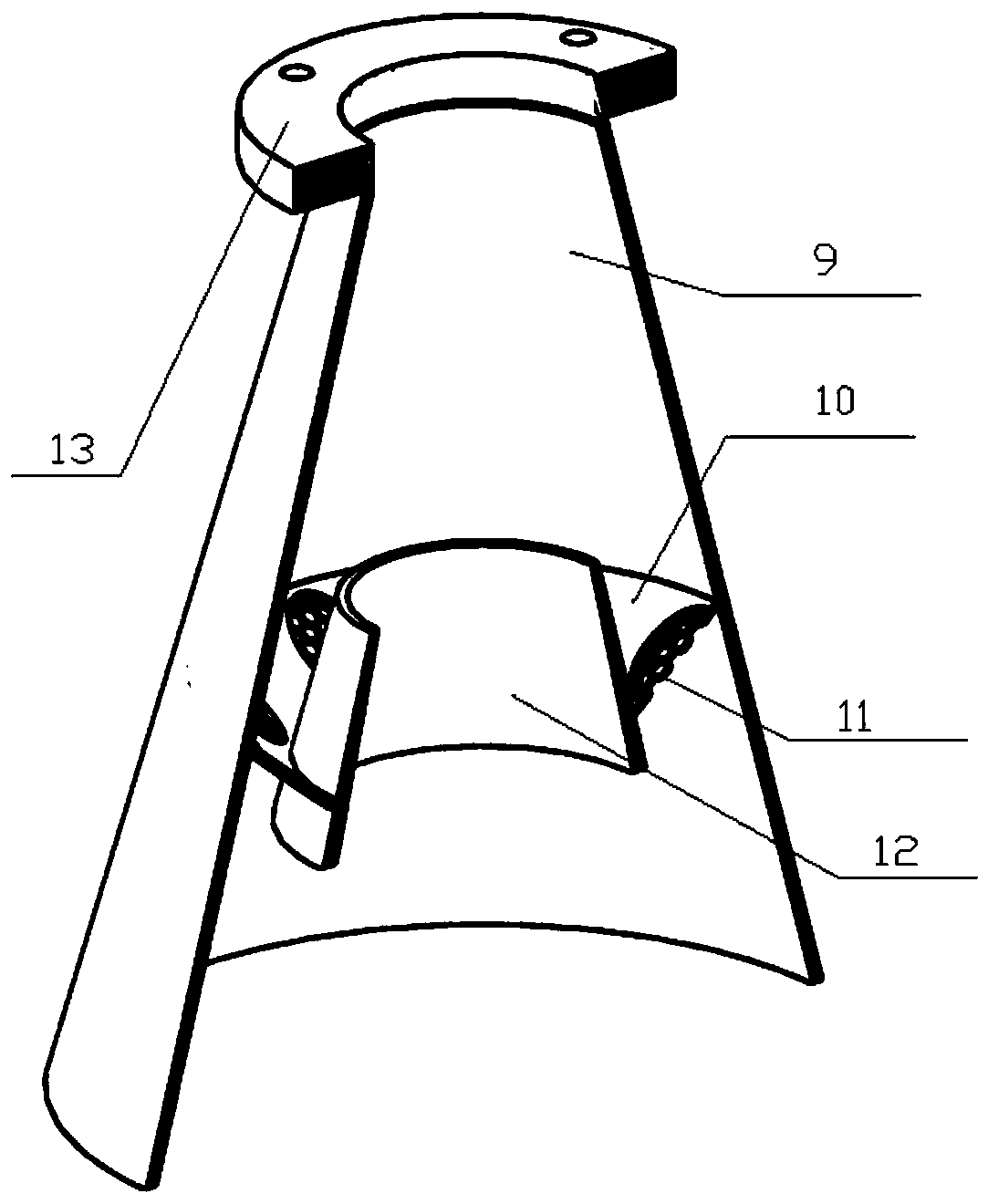

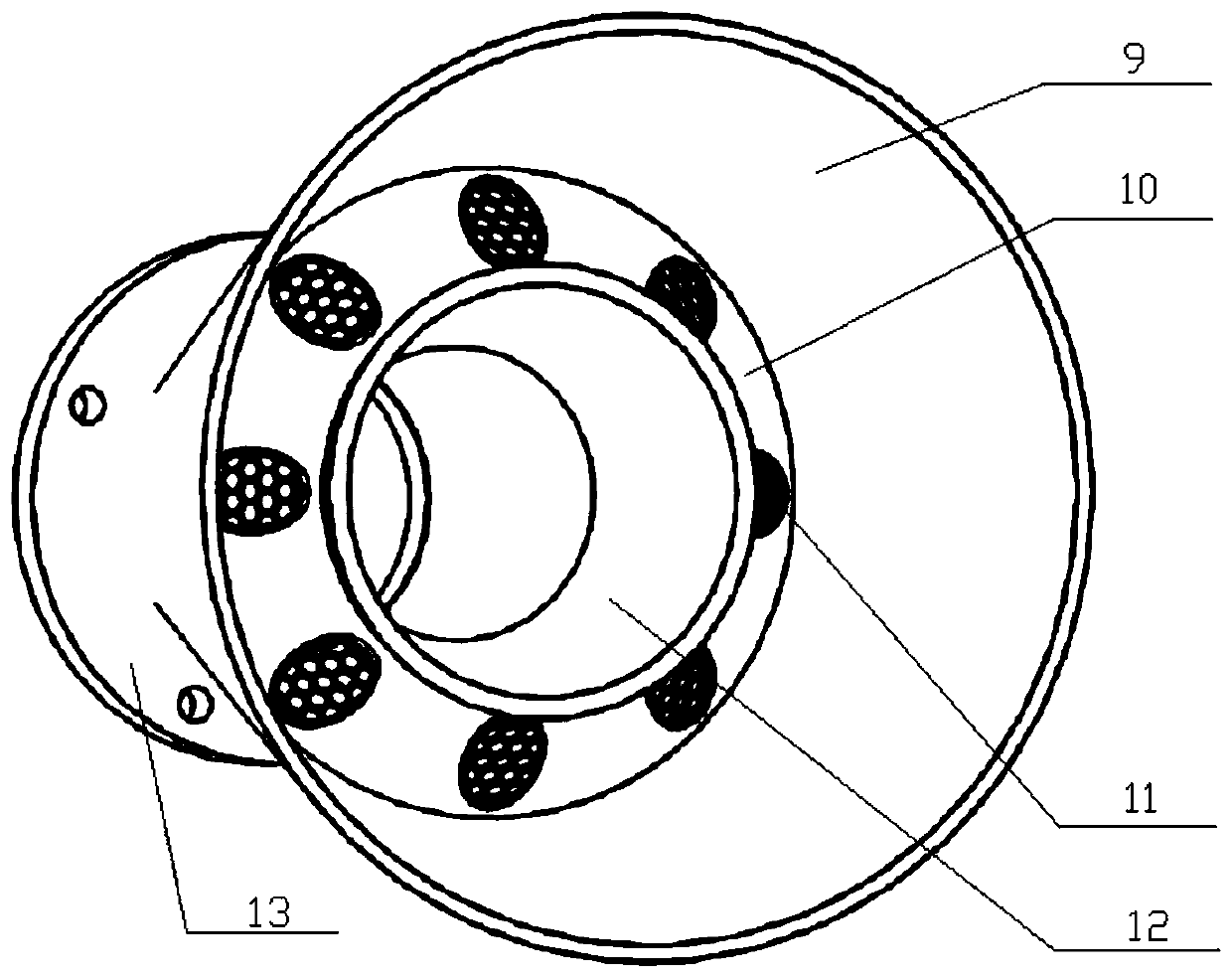

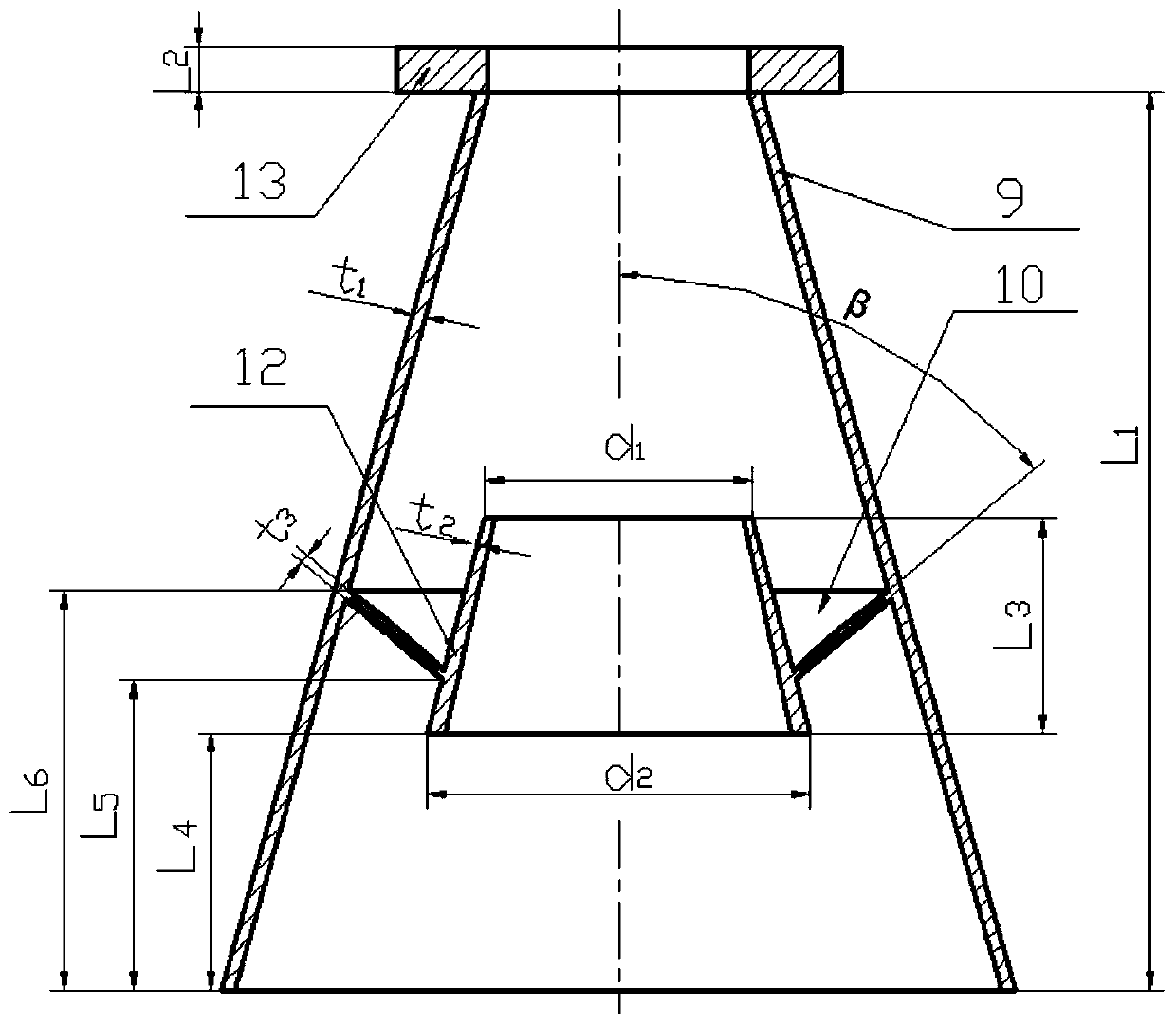

[0027] see figure 1 and figure 2 As shown, the draft tube 5 of the present invention is composed of a straight cone 9 , a diverter sheet 10 , an elliptical grid sheet 11 and a diverter cylinder 12 . The outermost is the straight cone 9, the axial section of the straight cone 9 is conical, the upper end of the straight cone 9 is the water inlet, which is the small end of the cone, and the lower end is the water outlet, which is the big end of the cone, and the straight cone 9 The inside is connected from the water inlet to the water outlet. A flange 13 is installed at the upper end of the straight cone 9 , and the straight cone 9 is fixed by the flange 13 .

[0028] A shunt 12 is arranged inside the straight cone 9 , the axial section of the shunt 12 is also a cone, and its central axis is collinear with the central axis of the straight cone 9 . The upper end of the shunt tube 12 is a small conical end, and the lower end is a large conical end. The shunt cylinder 12 is hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com