Large-size magnetic core glue removal sintering equipment and manufacturing method thereof

A kind of sintering equipment and large-scale technology, which is applied in the field of magnetic core processing, can solve the problems of poor debinding effect, uneven distribution of magnetic cores, cracking of degumming and other problems, and achieves the effect of convenient separate placement, short degumming time, and good volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

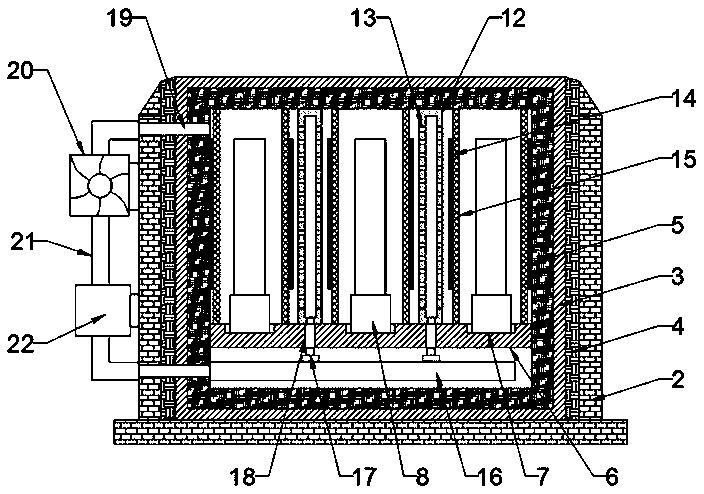

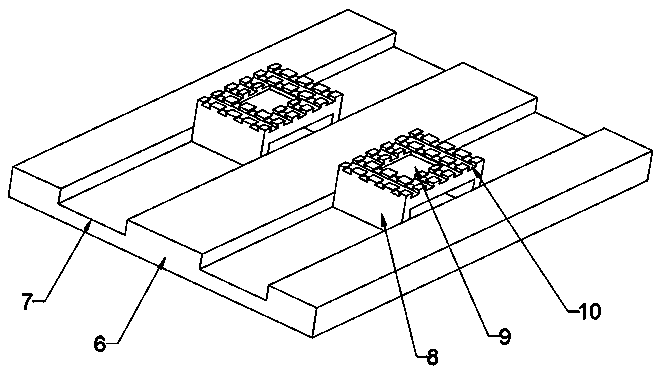

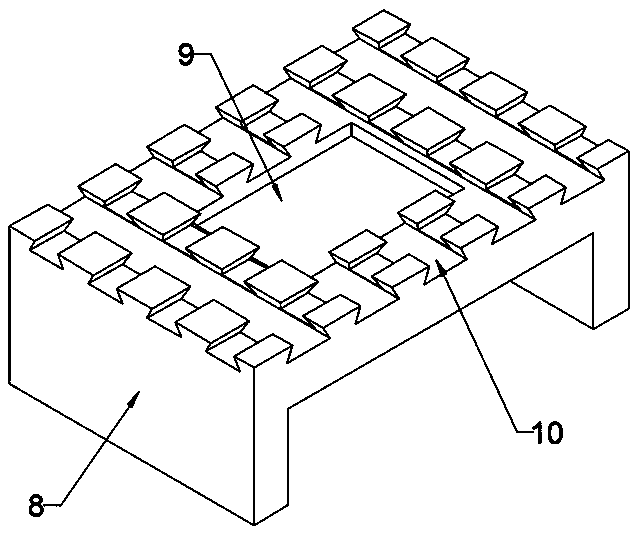

[0037] see Figure 1 to Figure 7 , a debinding and sintering equipment for large-size magnetic cores, including a sintering kiln body 1, a sintering base 8, a high-temperature air intake plate 12, a high-temperature heat circulation fan 20 and a return pipe 21, the sintering kiln body 1 is composed of a furnace base 2 , shell 3, insulation layer 4, furnace lining 5, hearth 6 and furnace door 11, the furnace base 2 is made of refractory bricks, the furnace base 2 is provided with a shell 3, preferably, the shell 3 is welded by stainless steel plate Formed, the furnace base 2 and the shell 3 are filled with an insulating layer 4 for reducing heat loss, and the insulating layer 4 can be high temperature resistant rock wool; the shell 3 is embedded with a furnace lining 5, and the shell 3 and the furnace lining 5 A hearth with a rectangular structure is formed. The bottom of the hearth is set as a hearth 6, and the hearth 6 is provided with a material return chute 7. The sintering...

Embodiment 2

[0051] see Figure 1 to Figure 7 , a debinding and sintering equipment for large-size magnetic cores, including a sintering kiln body 1, a sintering base 8, a high-temperature air intake plate 12, a high-temperature heat circulation fan 20 and a return pipe 21, the sintering kiln body 1 is composed of a furnace base 2 , shell 3, insulation layer 4, furnace lining 5, hearth 6 and furnace door 11, the furnace base 2 is made of refractory bricks, the furnace base 2 is provided with a shell 3, preferably, the shell 3 is welded by stainless steel plate Formed, the furnace base 2 and the shell 3 are filled with an insulating layer 4 for reducing heat loss, and the insulating layer 4 can be high temperature resistant rock wool; the shell 3 is embedded with a furnace lining 5, and the shell 3 and the furnace lining 5 A hearth with a rectangular structure is formed. The bottom of the hearth is set as a hearth 6, and the hearth 6 is provided with a material return chute 7. The sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com