Marine composite flat plate machinery mechanical property testing device

A composite material and mechanical mechanics technology, applied in the direction of measuring devices, analyzing materials, using stable tension/pressure to test the strength of materials, etc., can solve the problems of immature automatic testing devices, etc., and achieve convenient, fast and safe loading of water bladders. The test pressure range is large and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples describe the present invention in more detail.

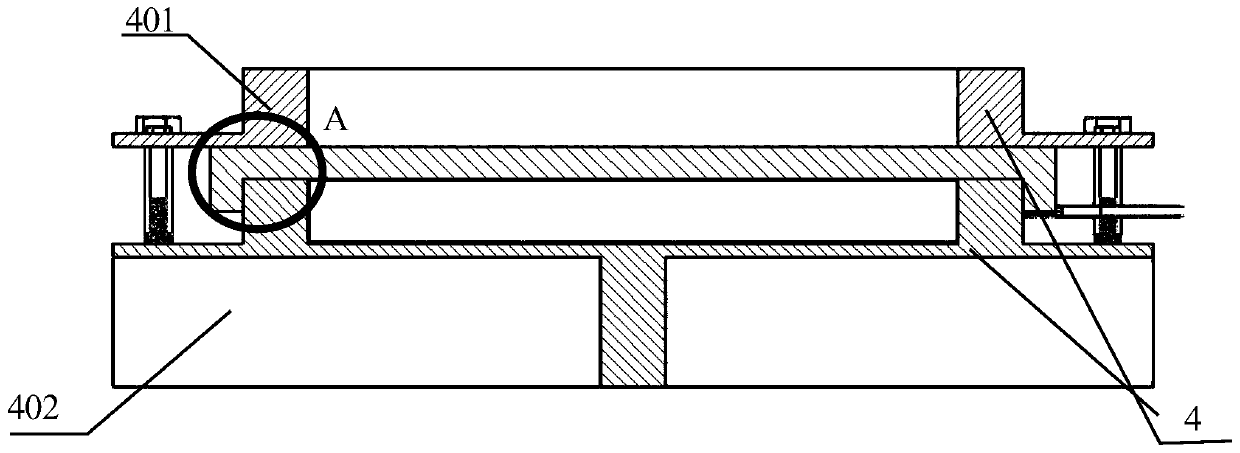

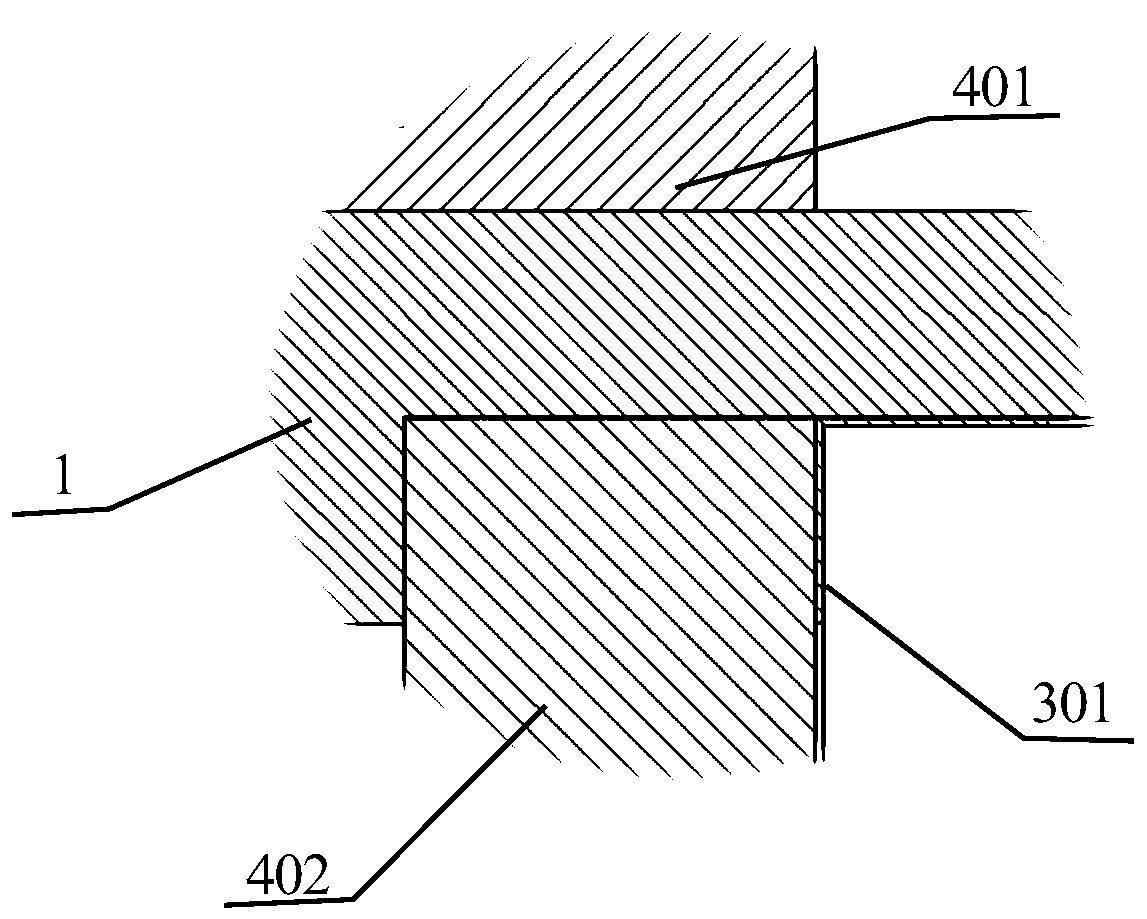

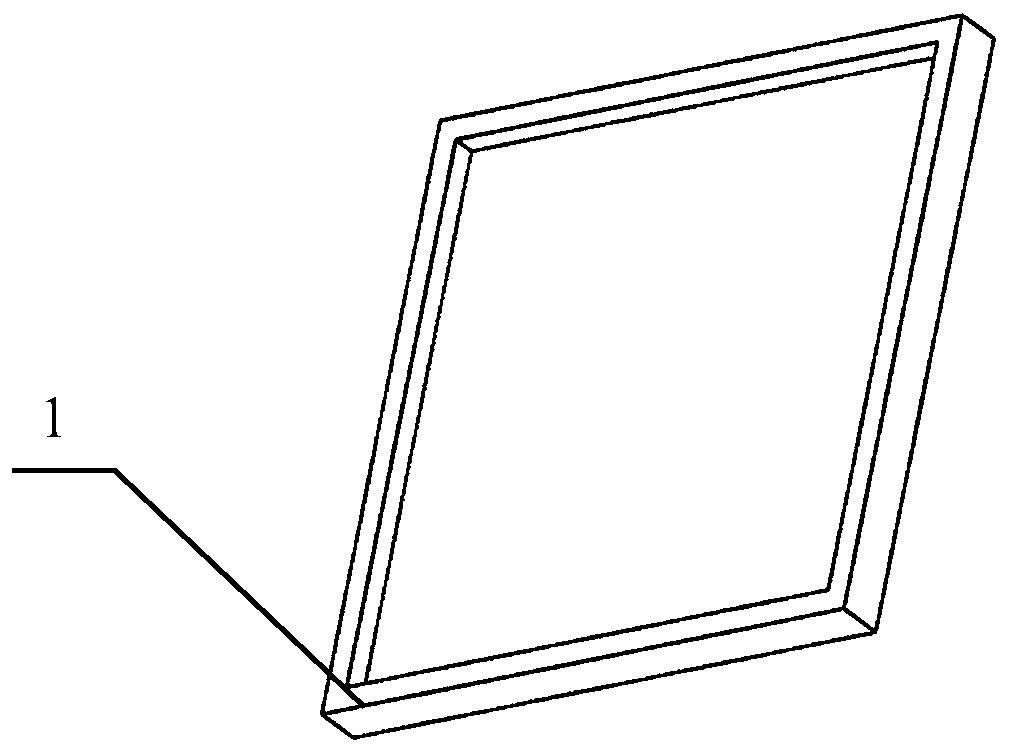

[0039] The hydraulic automatic test device for the mechanical properties of composite material plates for ships includes a composite material boundary rigid fixing device, a water bladder pressurization device, and an automatic control system. The automatic control system includes: automatic control terminal equipment, data processing unit, and data storage unit. . The automation control terminal equipment includes: a central processing unit, a display connected to it, a booster pump control line access port, a strain gauge control line access port, a displacement sensor control line access port, and a pressure sensor, a displacement collector, Displacement sensor, three-way strain gauge, static strain gauge. The access end of the booster pump control line is connected to the pressure sensor of the booster pump through the line, the access end of the strain gauge control line is connected to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com