Prediction model for turn-milling machining spatial spiral trochoid motion trail and an instantaneous cutting force

A technology of instantaneous cutting force and motion trajectory, applied in the field of mechanical processing and manufacturing, can solve the problems that cannot accurately reflect the status of turning and milling composite processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below with reference to the accompanying drawings and examples.

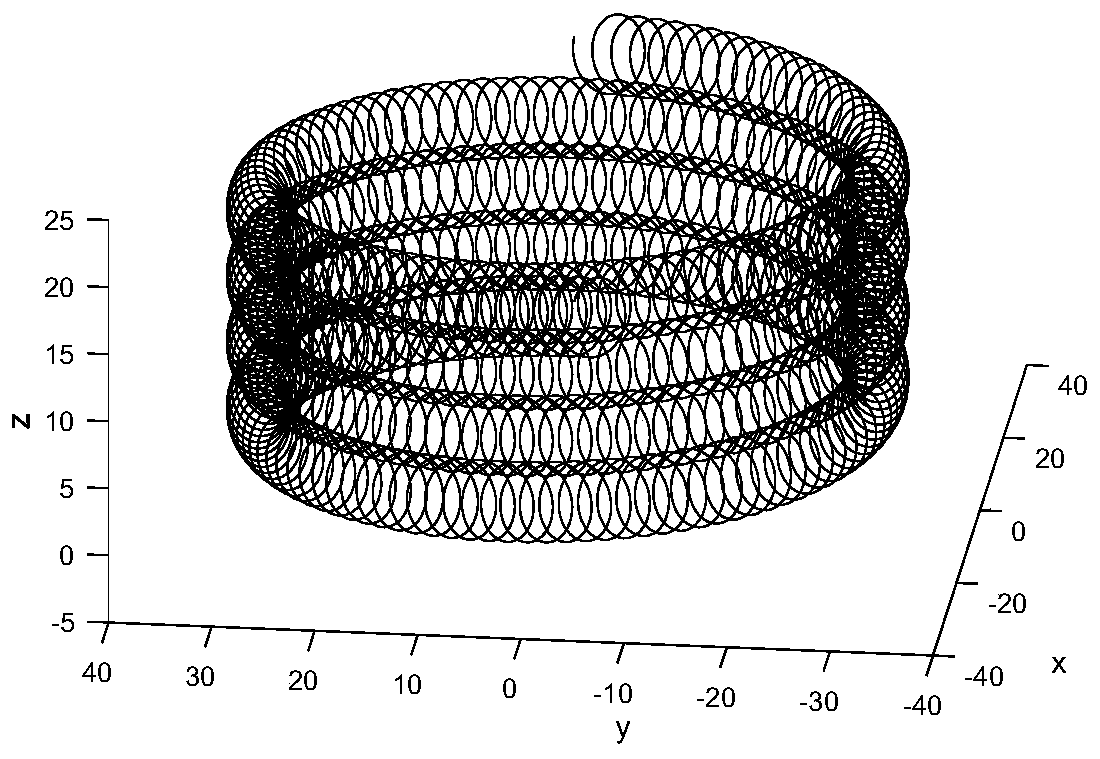

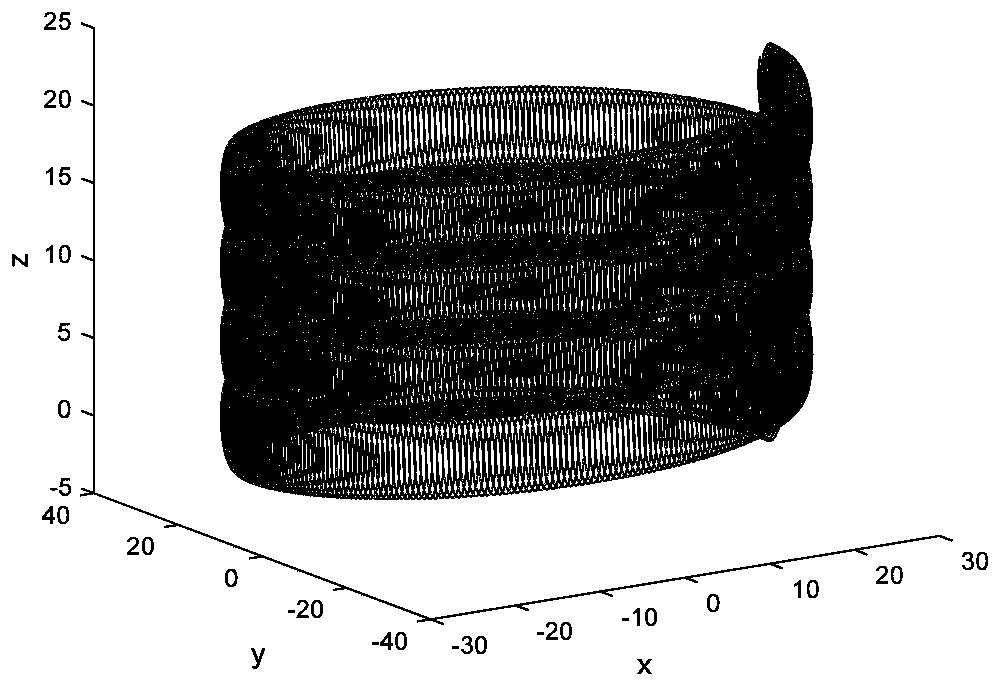

[0059] The invention provides a helical trochoid motion track and instantaneous cutting force prediction model in turning and milling processing space, such as Figure 4 As shown, the steps to implement the model are as follows:

[0060] Step 1: Establish workpiece coordinate system and tool coordinate system.

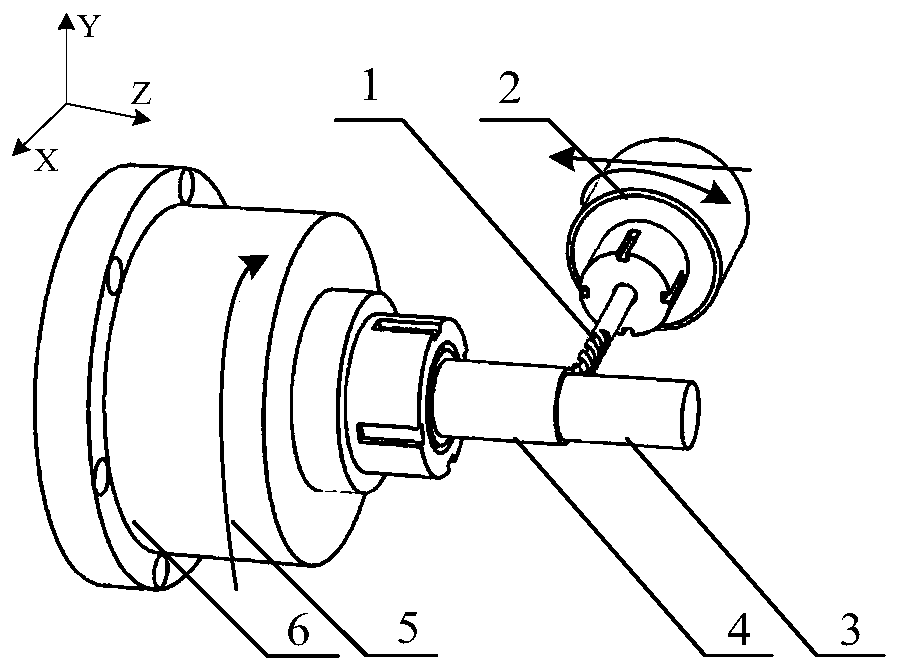

[0061] as attached figure 1 As shown, assume that the radius of the 4-axis section of the unprocessed workpiece is R, the right end is the workpiece processing surface 3, the radius of the end mill 1 is r, the milling cutter movement direction 2 and the workpiece rotation direction 5 are shown by the arrows in the figure; α p is the axial cutting depth of end mill 1; the rotational speed of workpiece 4 is n w , the unit is r / min; the speed of end mill 1 is n t , the unit is r / min; is the cutting angle in the Cartesian coordinate system, and θ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com