High-heat-resistant packaging substrate

A packaging carrier, high heat-resistant technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of self-encapsulation substrates such as glass and chip differences, and packaging structure thickness reduction obstacles, etc., to improve heat resistance. , increase the service life, improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

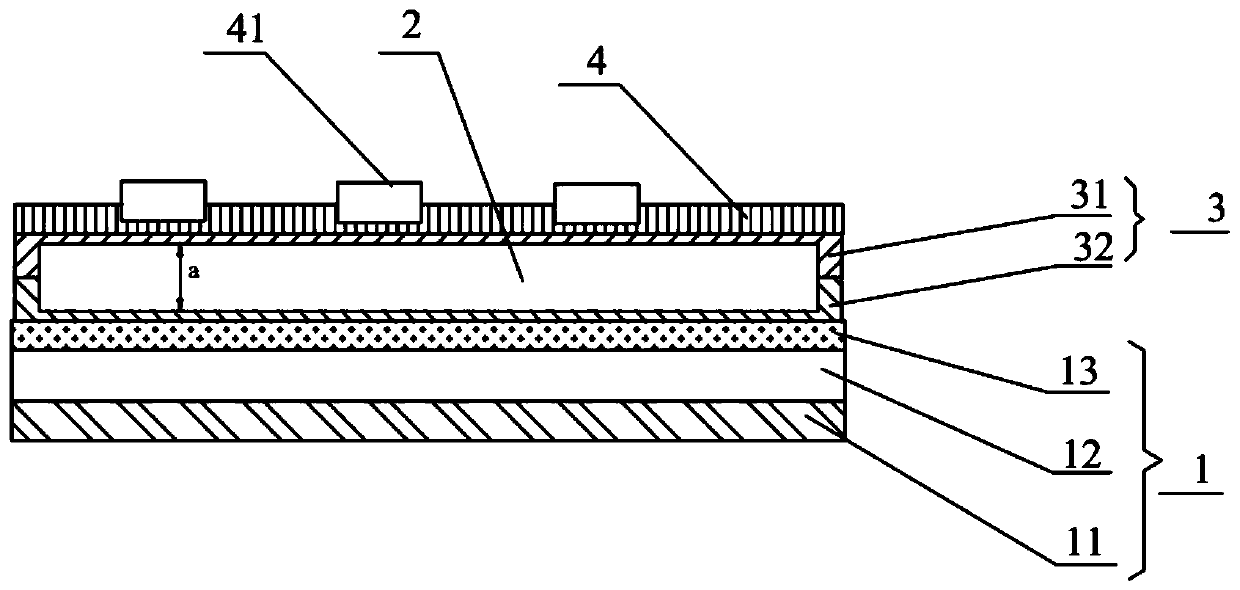

[0016] A high heat-resistant packaging carrier board, including a substrate 1, a circuit board 2, a high heat-resistant insulating layer 4, a patterned conductive layer 41 and a solder mask 3, the substrate 1 is sequentially composed of a release layer 13, A dielectric layer 12 and a copper foil layer 11 are formed. The circuit board 2 is located on the substrate 1 and is in contact with the release layer 13 of the substrate 1. A high heat-resistant insulating layer 4 is provided above the circuit board 2. A patterned conductive layer 41 is arranged on the upper part of the high heat-resistant insulating layer 4. Electronic components are arranged in the patterned conductive layer 41, and the electronic components are suitable for being arranged on the high heat-resistant insulating layer 4. The high heat-resistant The thermal expansion coefficient of the insulating layer 4 is between that of the substrate 1 and the electronic components. The solder resist layer 3 includes a fi...

Embodiment 2

[0021] A high heat-resistant packaging carrier board, including a substrate 1, a circuit board 2, a high heat-resistant insulating layer 4, a patterned conductive layer 41 and a solder mask 3, the substrate 1 is sequentially composed of a release layer 13, A dielectric layer 12 and a copper foil layer 11 are formed. The circuit board 2 is located on the substrate 1 and is in contact with the release layer 13 of the substrate 1. A high heat-resistant insulating layer 4 is provided above the circuit board 2. A patterned conductive layer 41 is arranged on the upper part of the high heat-resistant insulating layer 4. Electronic components are arranged in the patterned conductive layer 41, and the electronic components are suitable for being arranged on the high heat-resistant insulating layer 4. The high heat-resistant The thermal expansion coefficient of the insulating layer 4 is between that of the substrate 1 and the electronic components. The solder resist layer 3 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com