Automatic pre-bending device and bending method for motor rotor iron core

A motor rotor and pre-bending technology, applied in electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of large number of broken magnetic steel 19, easy damage to magnetic steel 19, hidden dangers to quality and safety, etc., to achieve crushing The effect of reducing the efficiency, eliminating the occurrence of defective products, and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

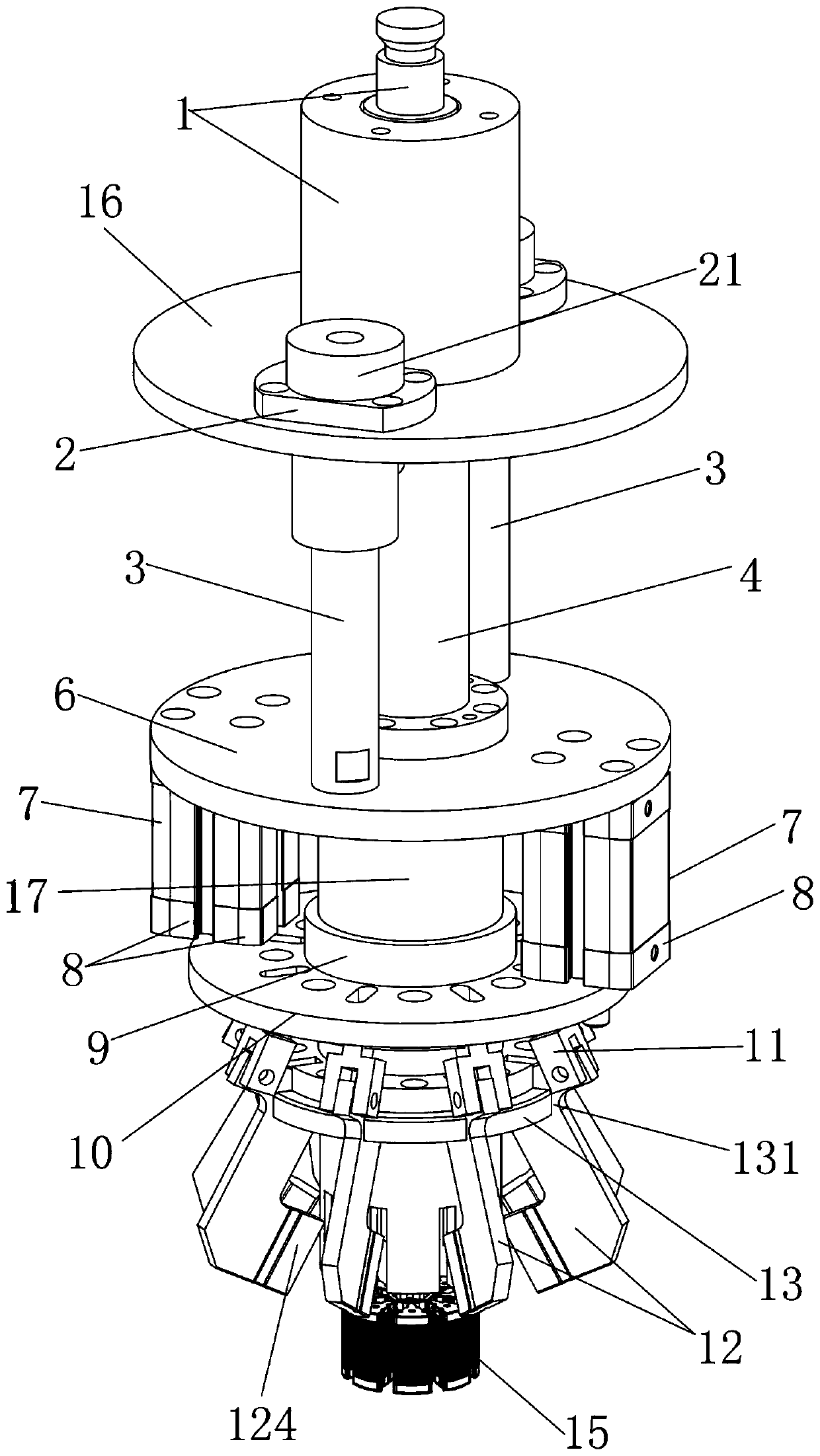

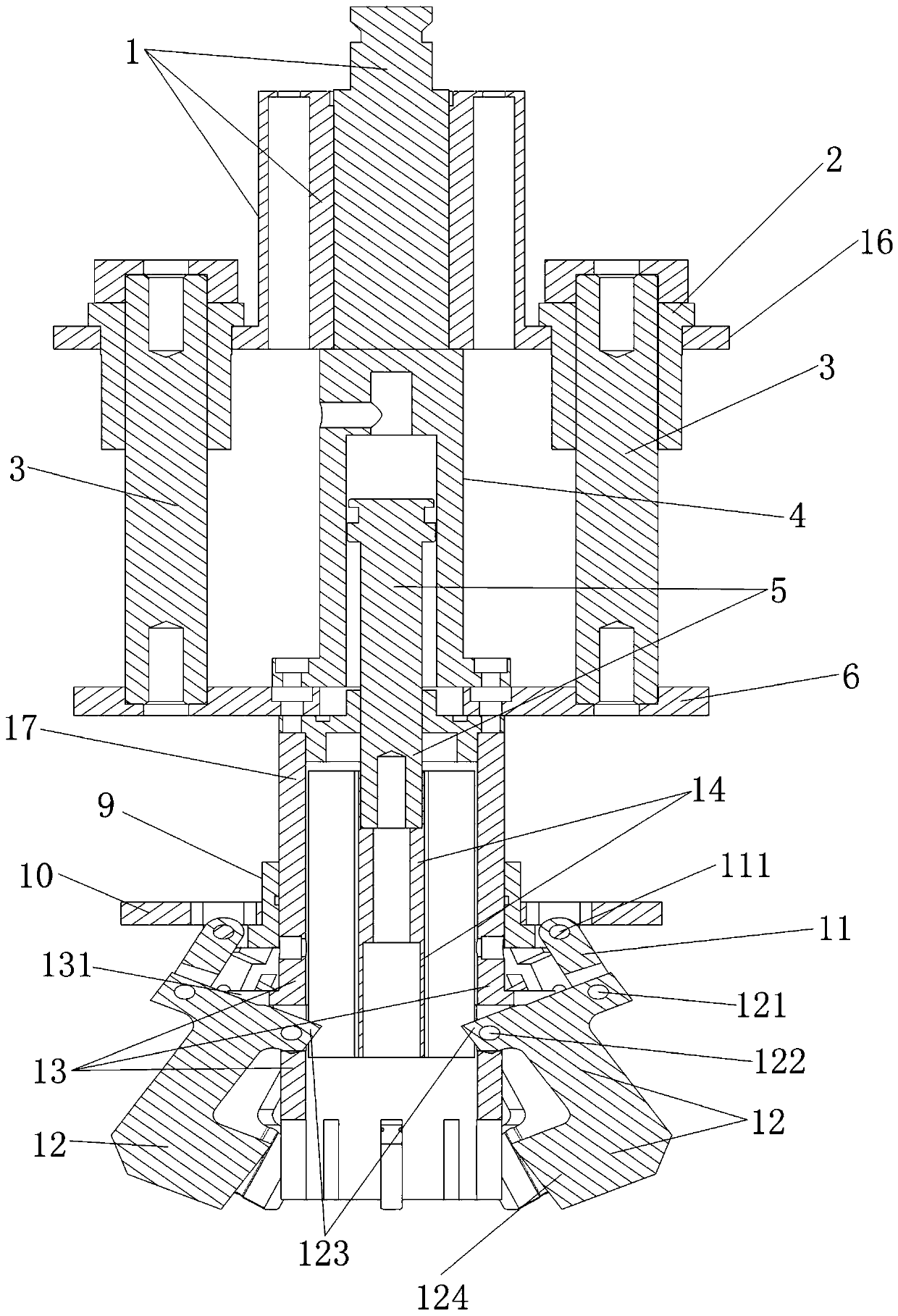

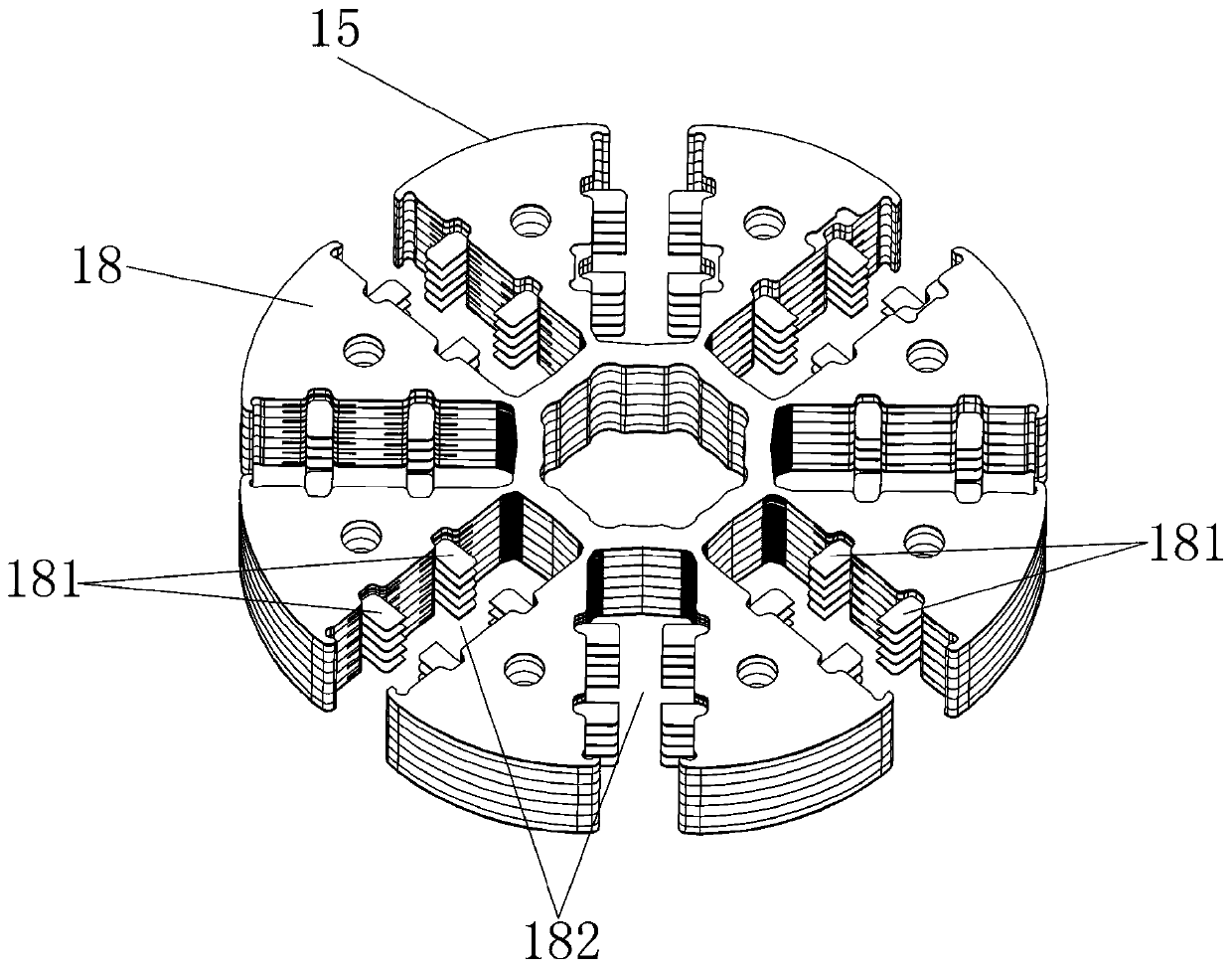

[0034] Such as Figure 1 to Figure 5 As shown, an automatic pre-bending device for a motor rotor core includes a mounting column 1, a top plate 16, a pressing cylinder 4, a clamping cylinder mounting plate 6, a clamping cylinder 7, a push plate 10 and a bending tool holder 13, A mounting column 1 is fixedly installed on the top of the top plate 16, and a down-pressing cylinder 4 is installed between the center of the top plate 16 and the center of the clamping cylinder mounting plate 6. The down-pressing cylinder 4 has a down-pressing piston rod 5, and the down-pressing cylinder 4 drives the down-pressing piston rod 5 telescopic movement. The bottom of the clamping cylinder mounting plate 6 is fixedly installed with a pressure head cylinder 17, and the lower end of the pressing piston rod 5 penetrates the center of the clamping cylinder mounting plate 6 and is placed in the pressure head cylinder 17 to lift and slide. The external sliding sleeve of the pressure head cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com