Waste gas conveying and treatment device for environment-friendly equipment

A technology of environmental protection equipment and processing devices, applied in transportation and packaging, mixers with rotating stirring devices, using liquid separation agents, etc., to achieve the effects of improving sealing, enhancing sealing, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

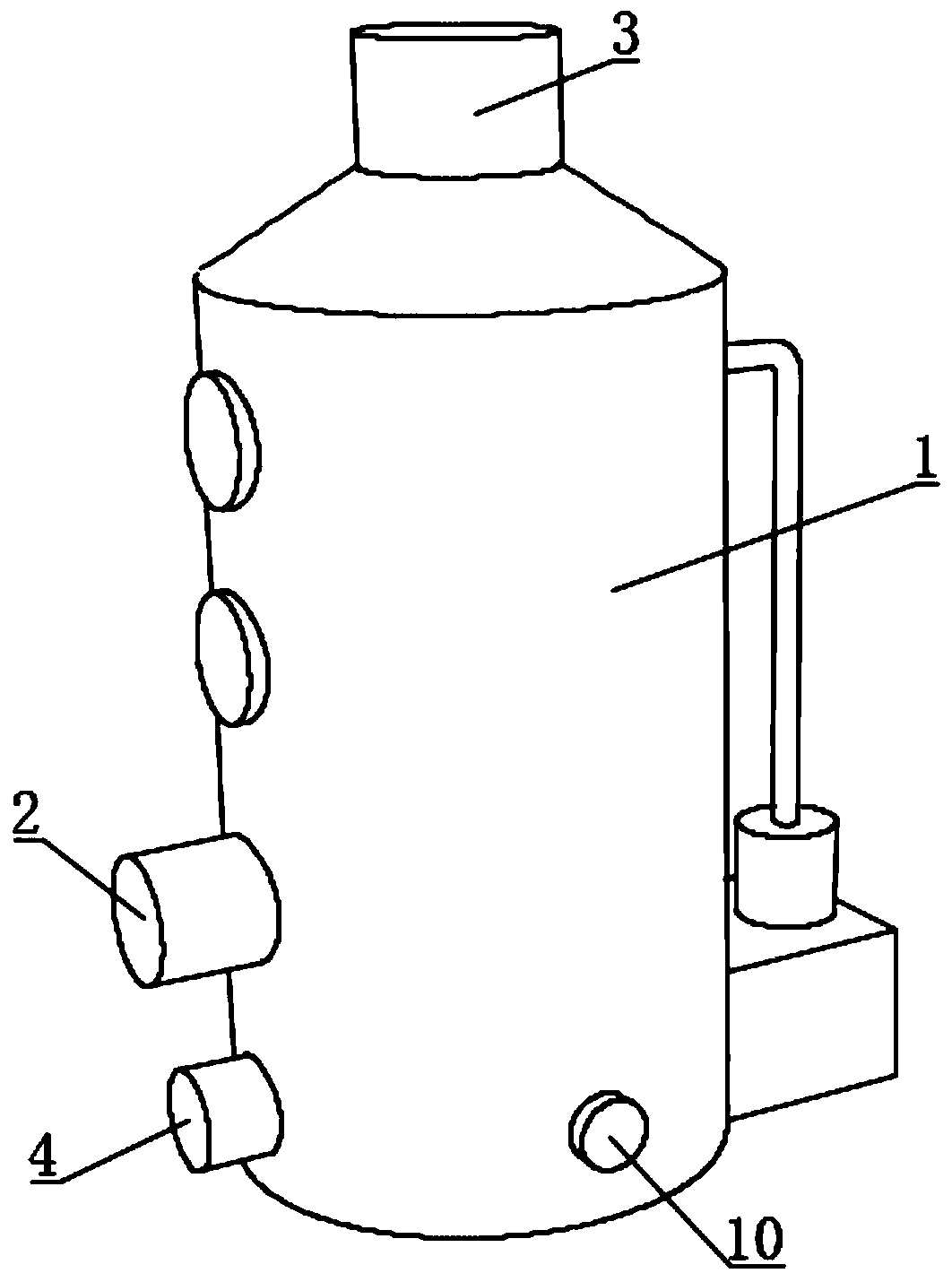

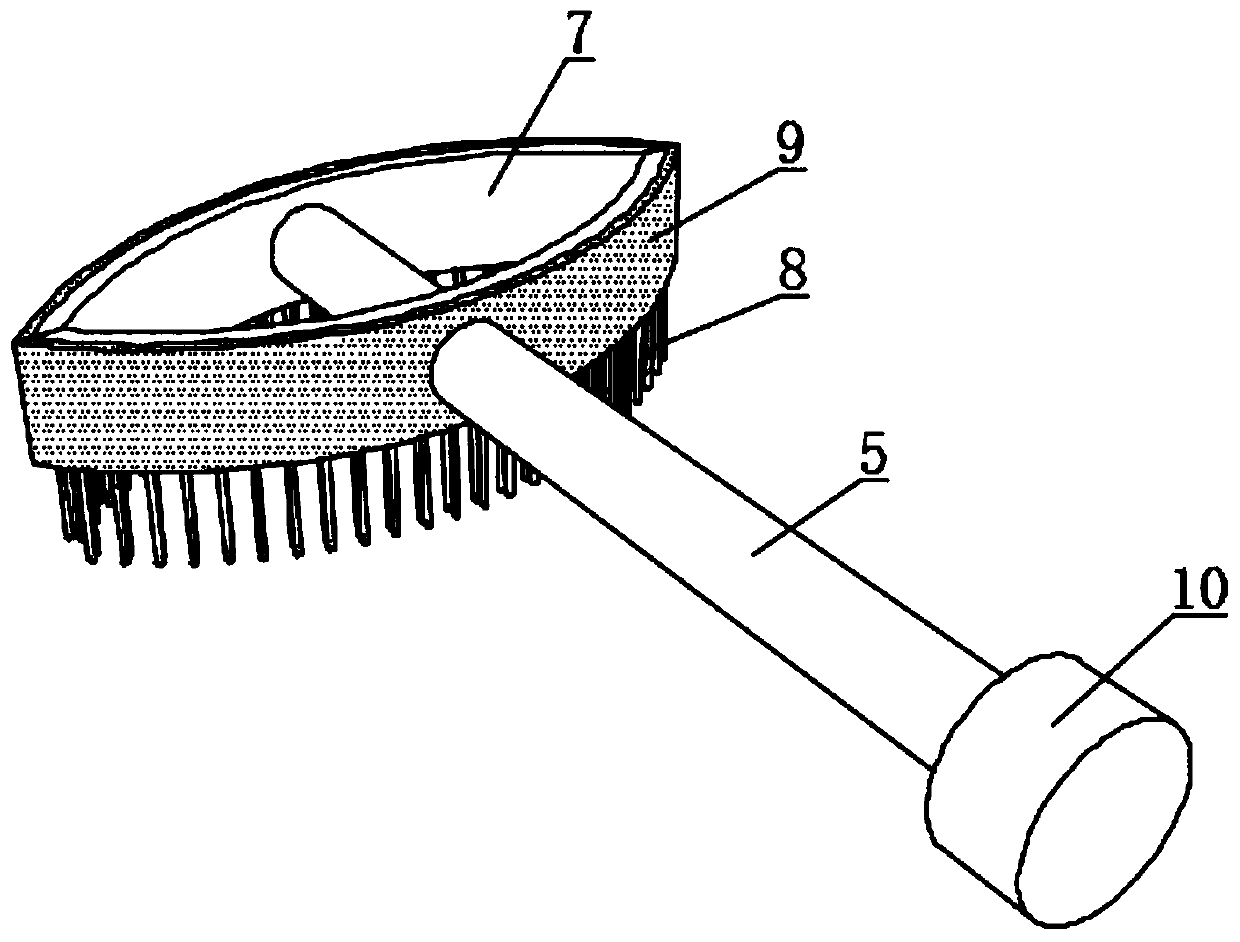

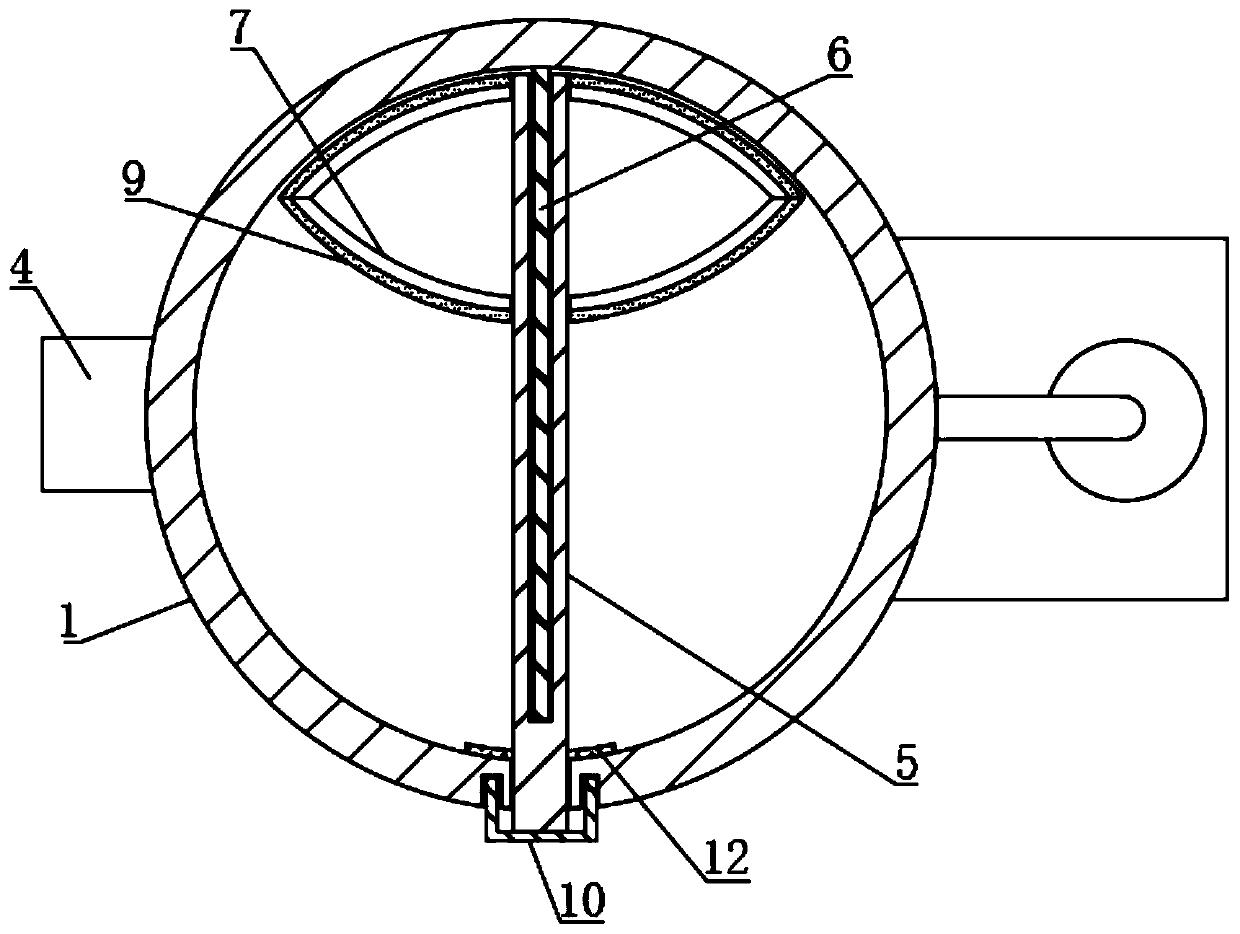

[0035] see figure 1 , a waste gas conveying and processing device for environmental protection equipment, comprising a tower body 1, an exhaust pipe 3 is arranged at the upper end of the tower body 1, an air intake pipe 2 and a sewage discharge pipe 4 are provided at the side end of the tower body 1, and the air intake pipe 2 is located at the sewage discharge pipe 4 on the upper side, see image 3 and Figure 4 The side end of the tower body 1 is dug with a round hole, the round hole is slidingly connected with a round rod 5, the inner wall of the tower body 1 is fixedly connected with a rectangular plate 6, and the end of the round rod 5 close to the rectangular plate 6 is dug with a rectangular groove 51, the rectangular The plate 6 is slidably connected to the inside of the rectangular groove 51, and the round rod 5 can move more stably through the rectangular plate 6. Please refer to figure 2 , the outer end of the round rod 5 is fixedly connected with a pair of mutual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com