Desulfurization slurry spraying device

A technology of spraying device and desulfurization slurry, which is applied in the direction of liquid spraying device, spraying device, liquid separation agent, etc., can solve the problems such as small overlap of desulfurization tower edges, non-crossing spray layers, and short circuit of flue gas, etc., to achieve improved Operational stability and reliability, solve the phenomenon of flue gas escape along the wall, improve the effect of desulfurization rate and dust removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

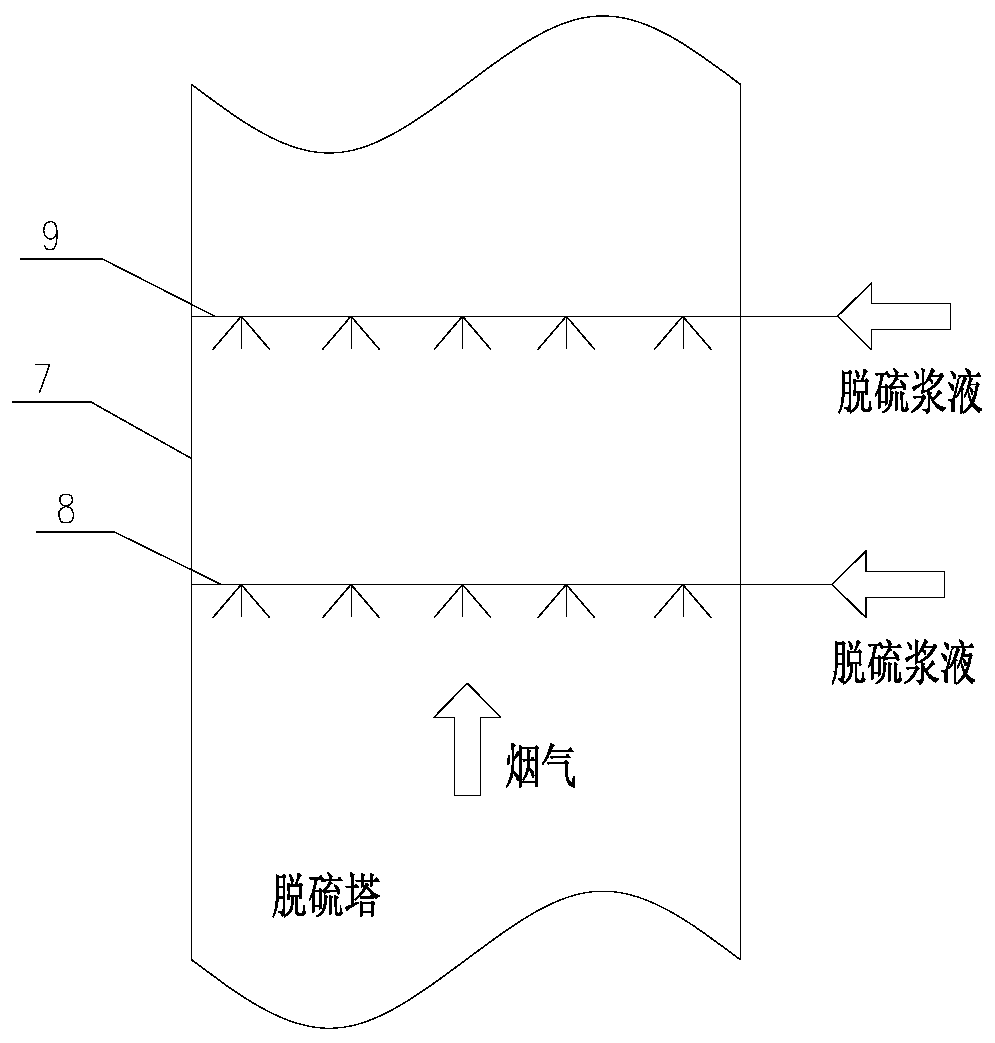

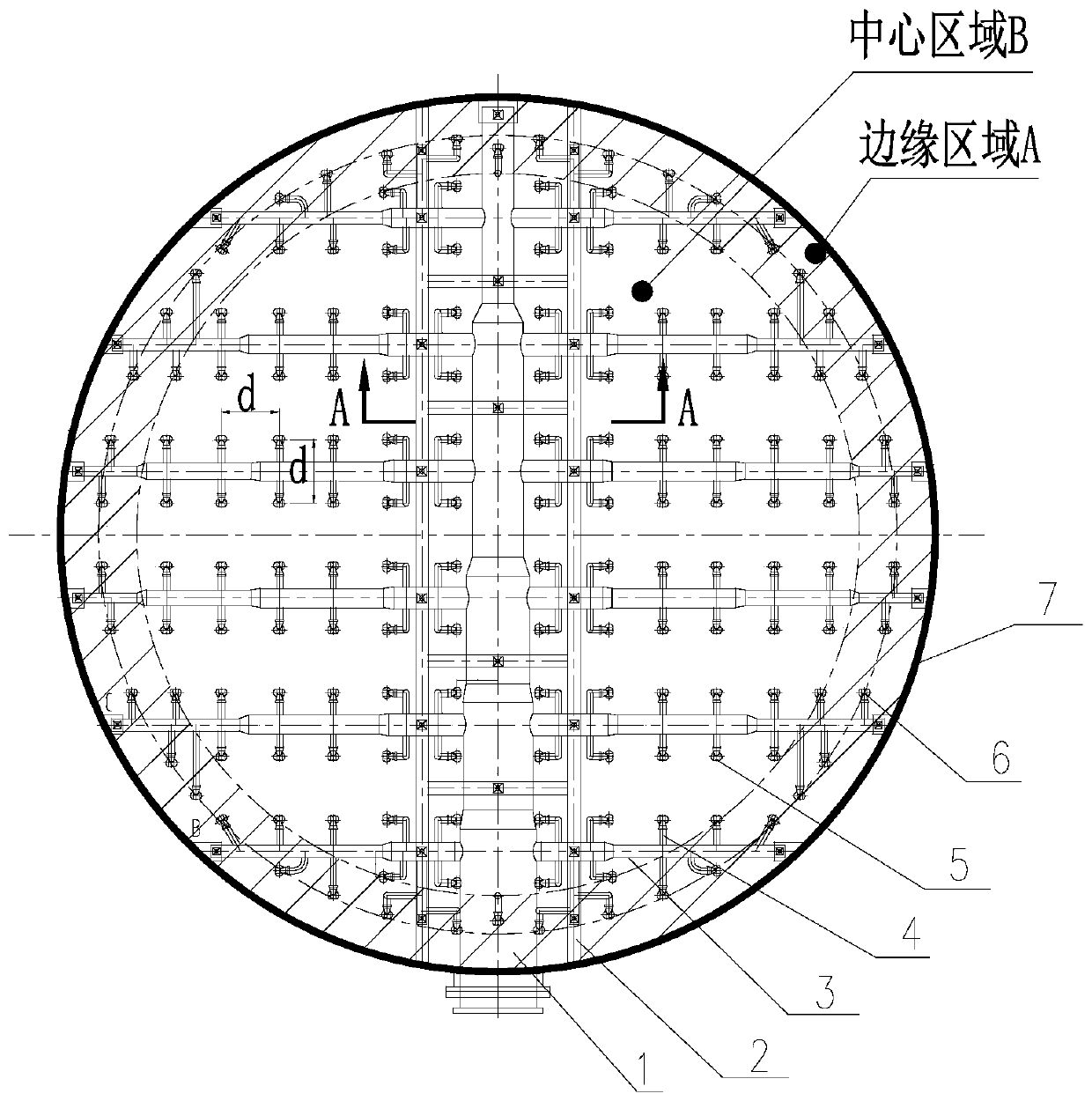

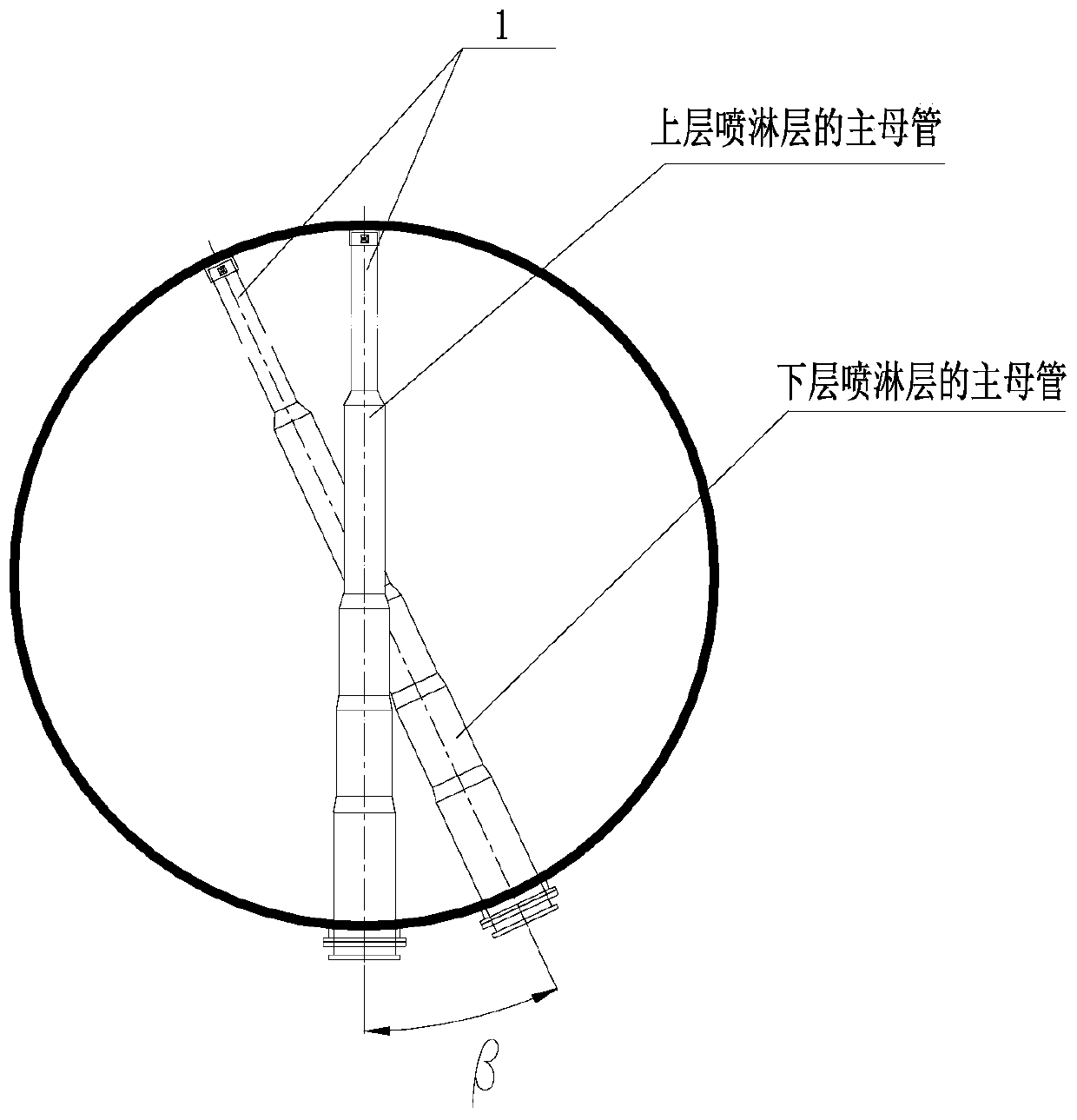

[0025] refer to Figure 1 to Figure 5 A desulfurization slurry spray device of the present invention is composed of more than two spray layers, the spray layers are sequentially arranged in the desulfurization tower from top to bottom, and the spray layers include main main pipe 1, support beam 2, secondary main pipe Pipe 3, branch pipe 4, first nozzle 5 and second nozzle 6, the main main pipe 1 is supported by a support beam 2, and the two ends of the support beam 2 are fixed on the tower wall 7 of the desulfurization tower. Both sides of the pipe 1 are connected with several secondary main pipes 3, and both sides of the secondary main pipe 3 are connected with several branch pipes 4, and the branch pipes 4 are not terminated with nozzles, and the nozzles include the first nozzle 5 or the second nozzle 6 , the two adjacent spray layers are composed of an upper spray layer 9 and a lower spray layer 8, the top view projection of the main master pipe 1 of the lower spray layer 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com