Pretreatment process of processing recycled polyester staple fiber by using waste polyester bottle flakes

A technology of polyester bottle flakes and recycled polyester, applied in recycling technology, cleaning method using liquid, detergent composition, etc., can solve the problems of large water consumption, shortening pulverization time, limited cleaning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

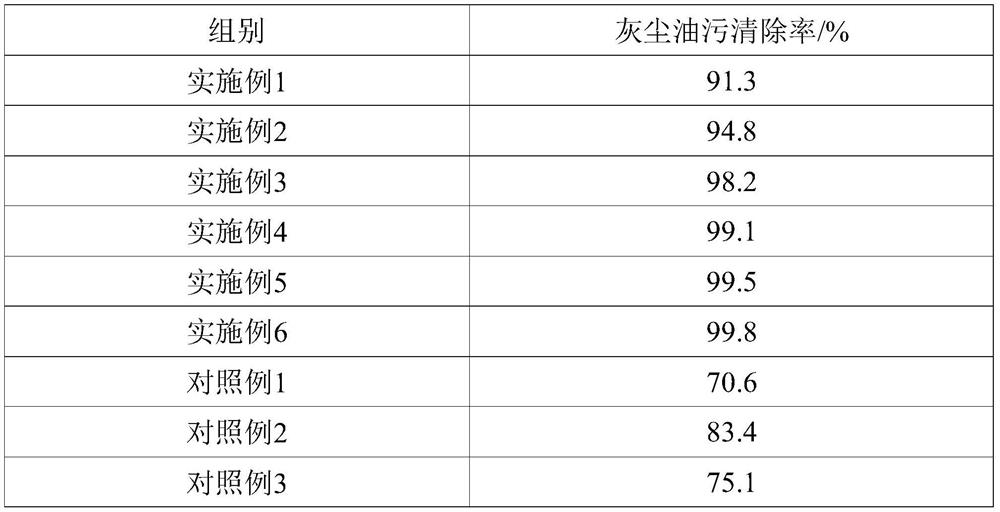

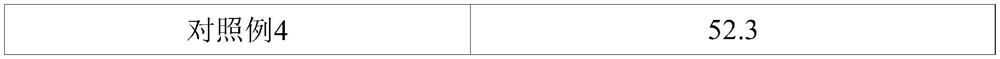

Examples

Embodiment 1

[0030] (1) Two-stage crushing: First, transfer 50kg of waste polyester bottle flakes into a freezer at 5-10°C, and then transfer them out after the first-stage freezing treatment. 8mm granules, then transfer the obtained granules into the freezer at 0-5°C, and then transfer them out after secondary freezing treatment. Polyester pellets;

[0031] (2) Cleaning: Send the obtained waste polyester particles into the drum type cleaning machine, inject 250kg of cleaning liquid into the drum type cleaning machine, the cleaning agent is made by dissolving water, and clean at a rotating speed of 500rpm, the cleaning time is 10min, and the cleaning is over Finally, discharge the cleaning solution, and then unload the waste polyester particles;

[0032] (3) Drying: Send the washed polyester granules into a tumble dryer at a drying temperature of 75-80°C, and dry at a rotating speed of 350rpm until the water content is lower than 0.5wt%;

[0033] (4) Micronization: Transfer the dried pol...

Embodiment 2

[0036] (1) Two-stage crushing: First, transfer 50kg of waste polyester bottle flakes into a freezer at 5-10°C, and then transfer them out after the first-stage freezing treatment. 8mm granules, then transfer the obtained granules into the freezer at 0-5°C, and then transfer them out after secondary freezing treatment. Polyester pellets;

[0037] (2) Cleaning: Send the obtained waste polyester particles into the drum type cleaning machine, inject 250kg of cleaning liquid into the drum type cleaning machine, the cleaning agent is made by dissolving water, and clean at a rotating speed of 500rpm, the cleaning time is 10min, and the cleaning is over Finally, discharge the cleaning solution, and then unload the waste polyester particles;

[0038] (3) Drying: Send the washed polyester granules into a tumble dryer at a drying temperature of 75-80°C, and dry at a rotating speed of 350rpm until the water content is lower than 0.5wt%;

[0039] (4) Micronization: Transfer the dried pol...

Embodiment 3

[0042] (1) Two-stage crushing: First, transfer 50kg of waste polyester bottle flakes into a freezer at 5-10°C, and then transfer them out after the first-stage freezing treatment. 8mm granules, then transfer the obtained granules into the freezer at 0-5°C, and then transfer them out after secondary freezing treatment. Polyester pellets;

[0043] (2) Cleaning: Send the obtained waste polyester particles into the drum type cleaning machine, inject 250kg of cleaning liquid into the drum type cleaning machine, the cleaning agent is made by dissolving water, and clean at a rotating speed of 500rpm, the cleaning time is 10min, and the cleaning is over Finally, discharge the cleaning solution, and then unload the waste polyester particles;

[0044](3) Drying: Send the washed polyester granules into a tumble dryer at a drying temperature of 75-80°C, and dry at a rotating speed of 350rpm until the water content is lower than 0.5wt%;

[0045] (4) Micronization: Transfer the dried poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com