Organic silica gel with high refractive index and preparation method thereof

A technology of refractive index and silicone, which is applied in the field of silicone gel with high refractive index and its preparation, can solve the problem of affecting the light transmittance of the gel, and the occasions that require high light transmittance cannot fully meet the use requirements, gel transmittance, etc. The effect of high refractive index and light transmittance can be achieved without the influence of light rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

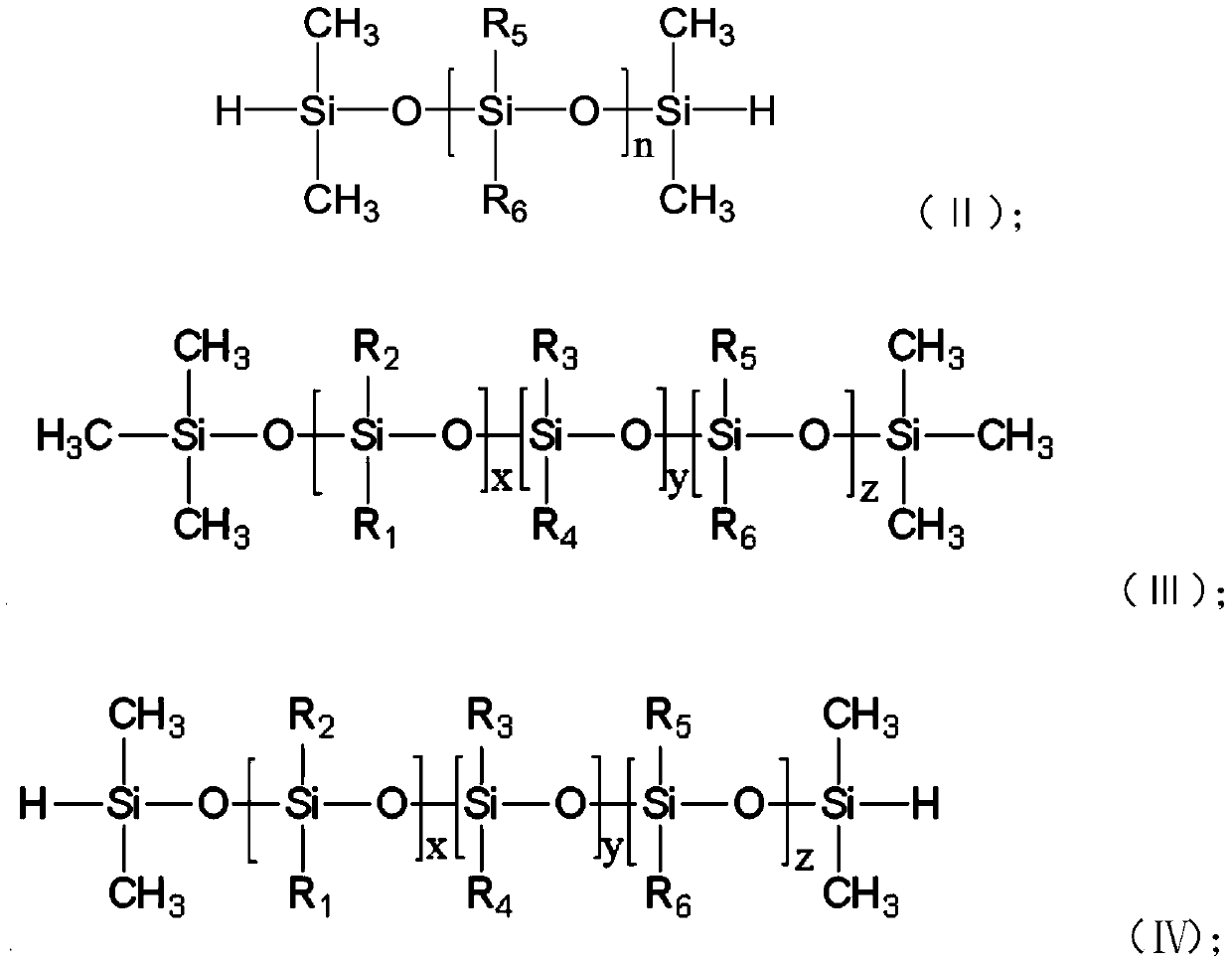

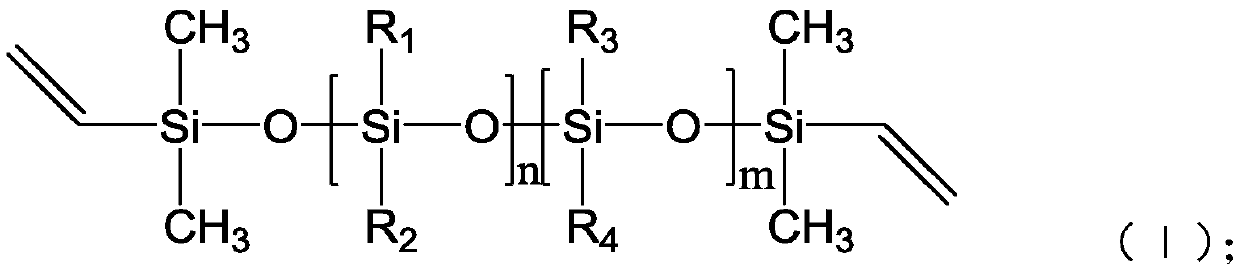

[0065] The present application also provides a preparation method of the above-mentioned organosilicon gel, comprising the following steps:

[0066] Mix vinyl-terminated phenyl-containing silicone oil, hydrogen-terminated phenyl-containing silicone oil, phenyl hydrogen-containing silicone oil and inhibitor to obtain component A;

[0067] Mixing vinyl-terminated phenyl-containing silicone oil and platinum catalyst to obtain component B;

[0068] Mix component A and component B and then cure to obtain a silicone gel with high refractive index.

[0069] In the above preparation process, the raw materials have been described in detail and will not be repeated here.

[0070] After the above components A and B are mixed, the molar ratio of vinyl groups to silicon-hydrogen bonds in the resulting mixture is greater than 1, and only when the amount of vinyl groups is greater than the amount of hydrogen can a stable gel be formed.

[0071] The above-mentioned curing is a curing method...

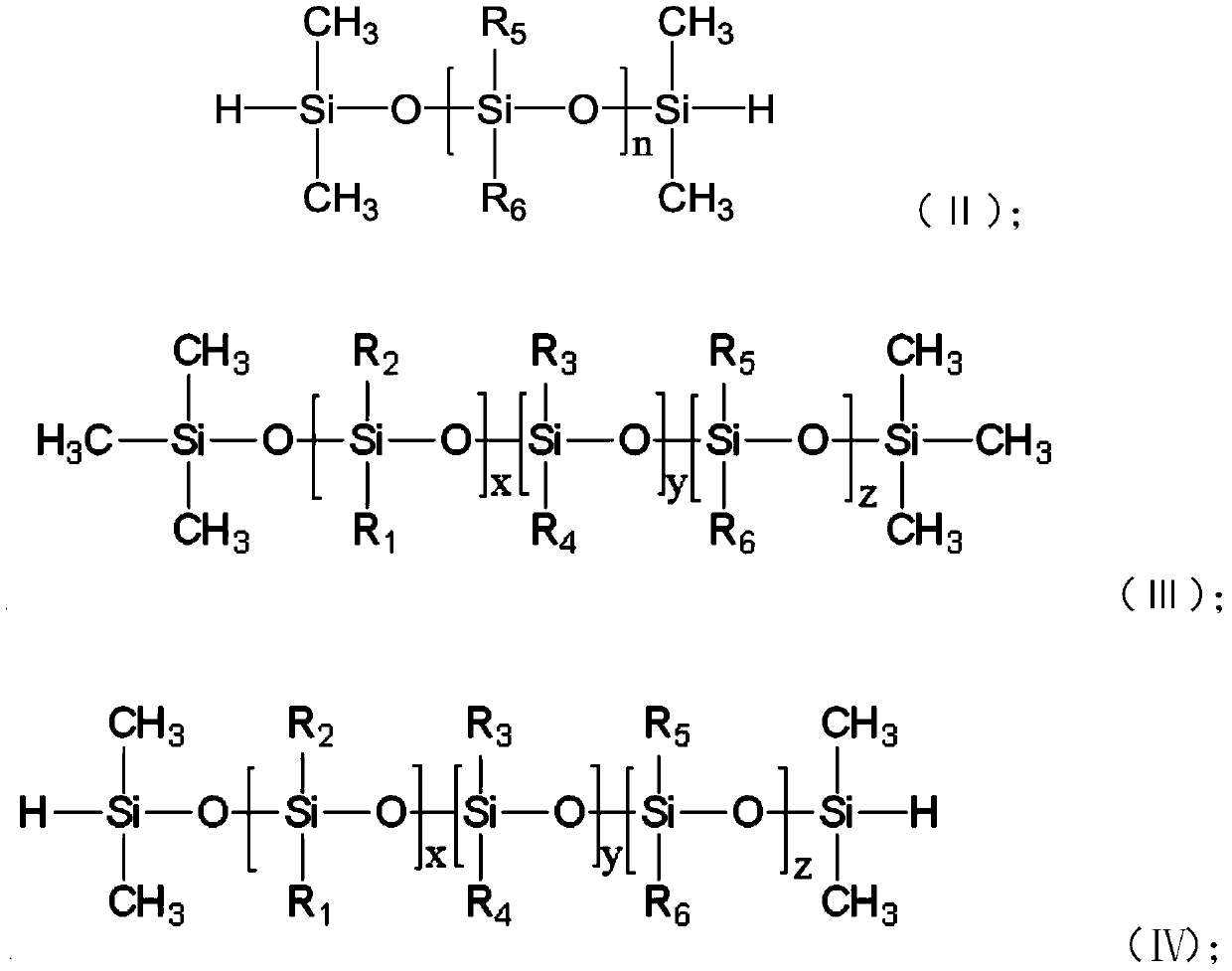

Embodiment 1

[0075] Mix vinyl-terminated phenyl-containing silicone oil, hydrogen-terminated phenyl-containing silicone oil, phenyl hydrogen-containing silicone oil and inhibitors uniformly according to the proportion to obtain component A;

[0076] Mix vinyl-terminated phenyl-containing silicone oil and platinum catalyst uniformly according to the proportion to obtain component B;

[0077] The silicone gel can be obtained after mixing component A and component B according to the weight ratio of 1:1 and curing them evenly.

[0078] The content and relevant parameters of the above-mentioned A component and B component are specifically shown in Table 1;

[0079] The component content data sheet of table 1 embodiment 1

[0080]

[0081]

Embodiment 2

[0083] Mix vinyl-terminated phenyl-containing silicone oil, hydrogen-terminated phenyl-containing silicone oil, phenyl hydrogen-containing silicone oil and inhibitor according to the proportion to obtain component A;

[0084] Mix vinyl-terminated phenyl-containing silicone oil and platinum catalyst uniformly according to the proportion to obtain component B;

[0085] The silicone gel can be obtained after mixing component A and component B according to the weight ratio of 1:1 and curing them evenly.

[0086] The content and relevant parameters of the above-mentioned A component and B component are specifically shown in Table 2;

[0087] The component content data table of table 2 embodiment 2

[0088]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com