High-speed aircraft capable of achieving drag reduction and range extension

A high-speed aircraft and cover technology, applied in the types of weapons, offensive equipment, projectiles, etc., can solve the problems of inability to find a solution, large resistance of missiles and aircraft, and reduce resistance, improve the effect of drag reduction, and avoid turbulence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

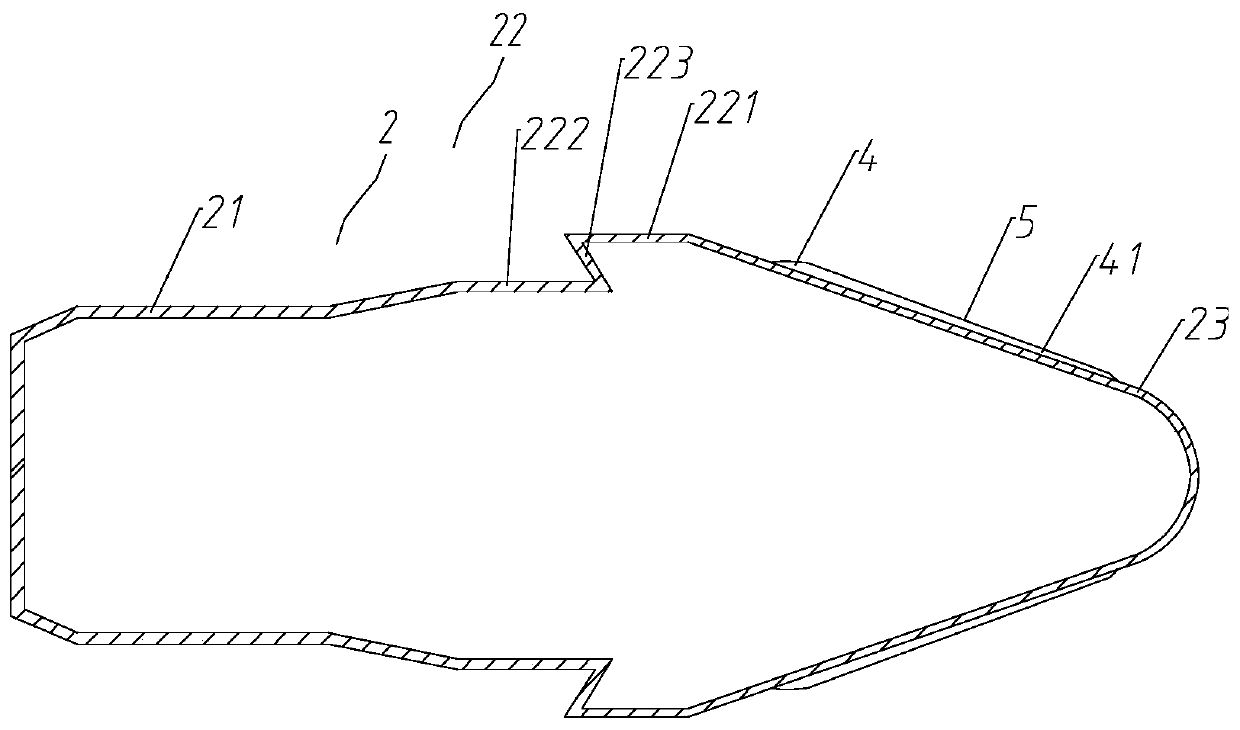

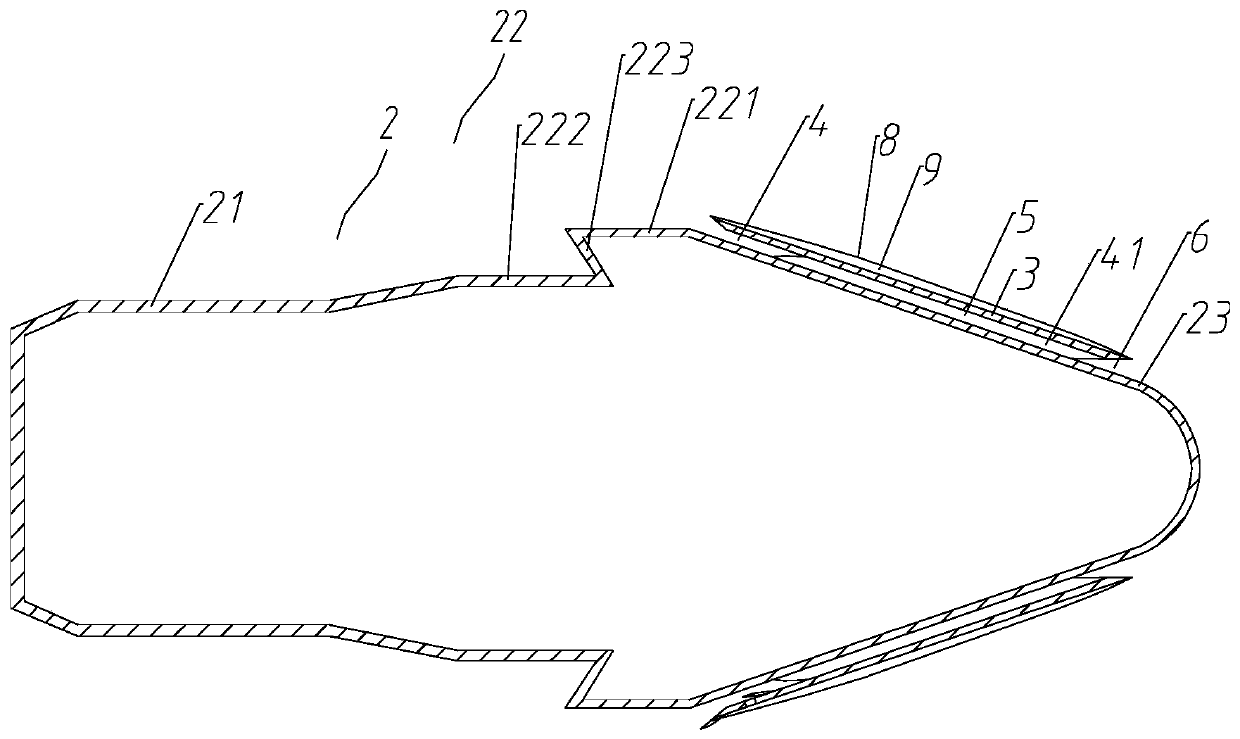

[0032] Such as Figure 1 ~ Figure 2 As shown, the present invention proposes a drag-reducing and range-extending high-speed aircraft, including

[0033] The main housing 2, the main housing 2 includes a tail housing 21, a platform stage 22, and a head housing 23 that are connected in sequence and are all cylindrical. The front end of the head housing 23 is tapered.

[0034] The head shell 23 is provided with a cylindrical cover body 3 coaxial with the head shell 23, the front end of the cover body 3 is conical, and a channel 4 is formed between the cover body 3 and the head shell 23. The channel 4 is divided into several first strip-shaped channels 41 parallel to each other by the first ribs 5, one side of the first ribs 5 is connected with the inner wall of the head housing 23, and one side is connected with the inner wall of the cover body 3, The front end of the first strip channel 41 is an inlet 6, and the tail end is an outlet 7, and the outlet 7 is close to the platform...

Embodiment 2

[0045] Including all the structures in Example 1, at the same time, the first rib 5 and the second rib 8 are helical, and the direction of rotation is consistent with the surface precession direction when the projectile is flying, thus becoming a helical rib precession scheme, adjacent to the second rib The parts of the two ribs 8 close to the cover body 3 are in contact with each other, and are in the shape of closely arranged teeth, which can better achieve the effect of reducing drag.

Embodiment 3

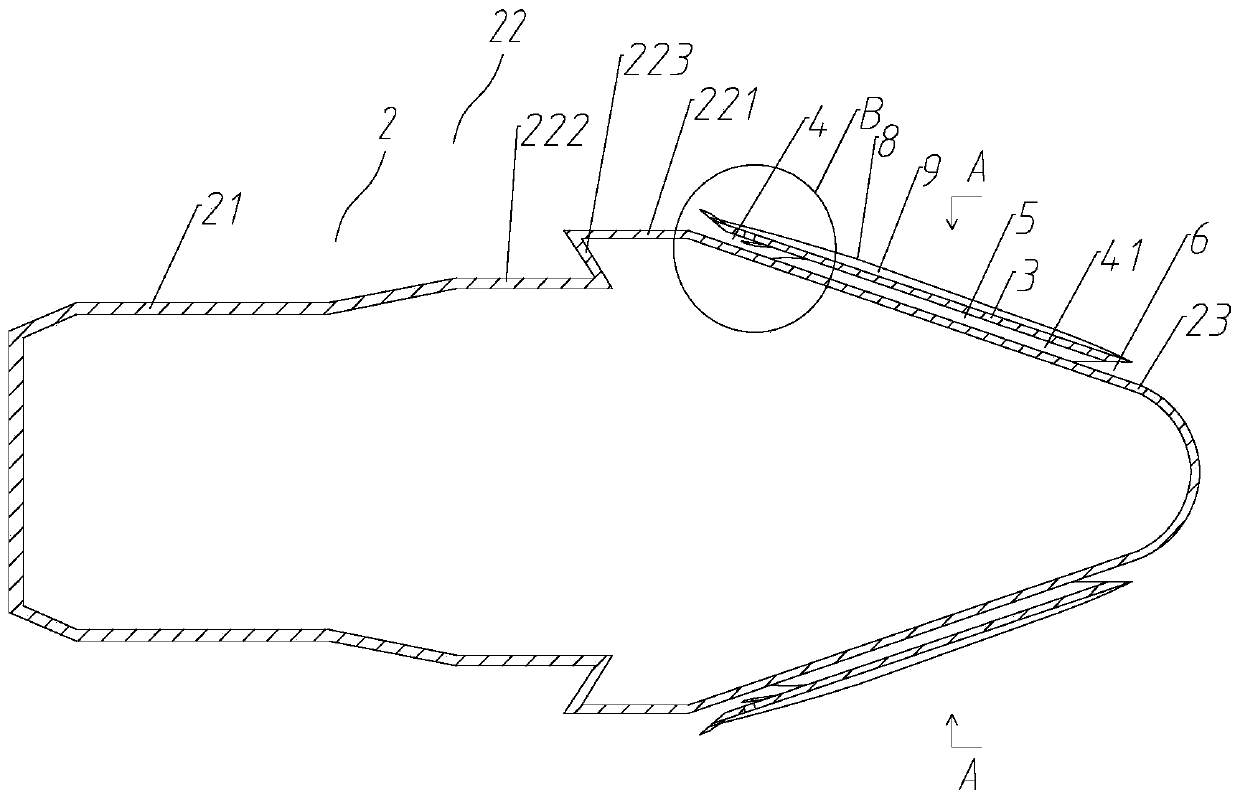

[0047] Such as Figure 3 ~ Figure 5 As shown, a kind of drag-reducing and range-extending high-speed aircraft proposed by the present invention includes all the structures of embodiment 1,

[0048] Further, the length of the first strip-shaped passage 41 is 1 / 2 to 3 / 4 of the length of the second strip-shaped passage 9 .

[0049] Further, the inner wall of the end of the cover body 3 near the outlet 7 is provided with a cylindrical variable-diameter spoiler 10, the diameter of the variable-diameter spoiler 10 gradually decreases from the front end to the rear end, and the outer wall of the variable-diameter spoiler 10 is in contact with the cover. A suction flow space 11 is formed between the inner walls of the body 3 , and a through hole 12 is provided on the cover body 3 , and the through hole 12 communicates with the flow suction space 11 and the second strip-shaped channel 9 .

[0050] Further, the tail of the cover body 3 is also connected with a diameter-reducing body 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com