Novel gauge-changeable bogie track-changing function and reliability test bed

A reliability and test-bed technology, applied in the direction of railway vehicle testing, etc., can solve the problems of changing gauge bogies, etc., and achieve the effects of strong overall bearing capacity, improved reliability and safety, and low motion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

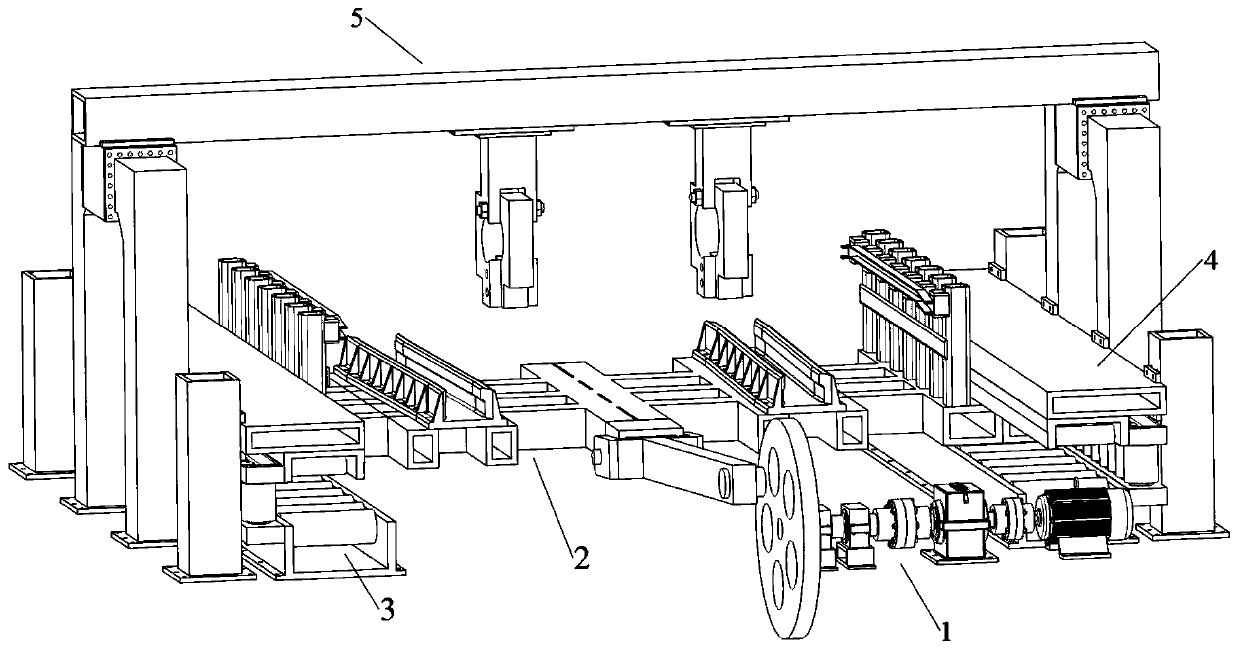

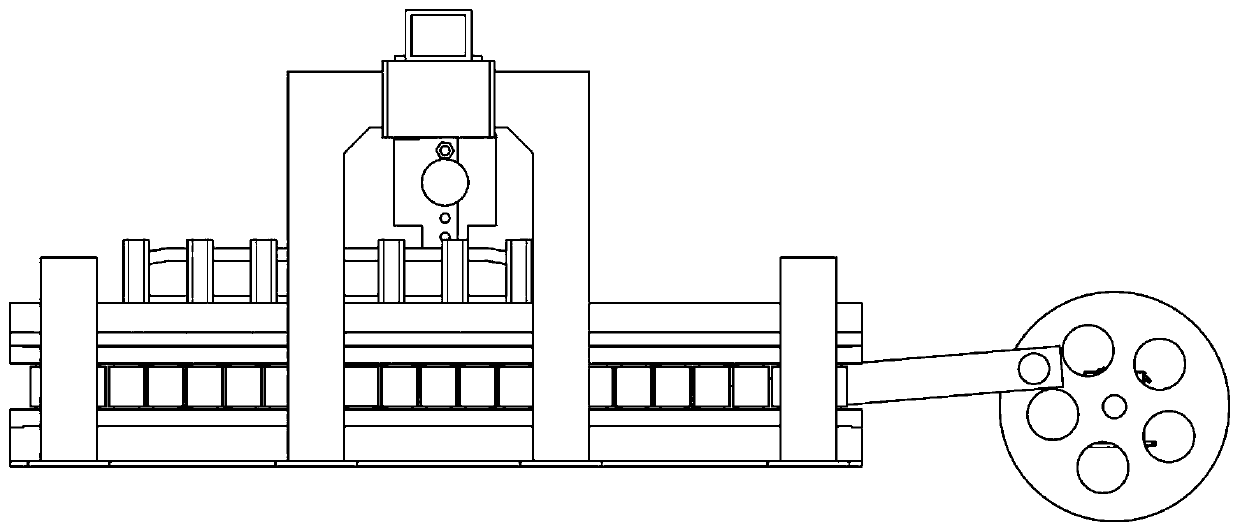

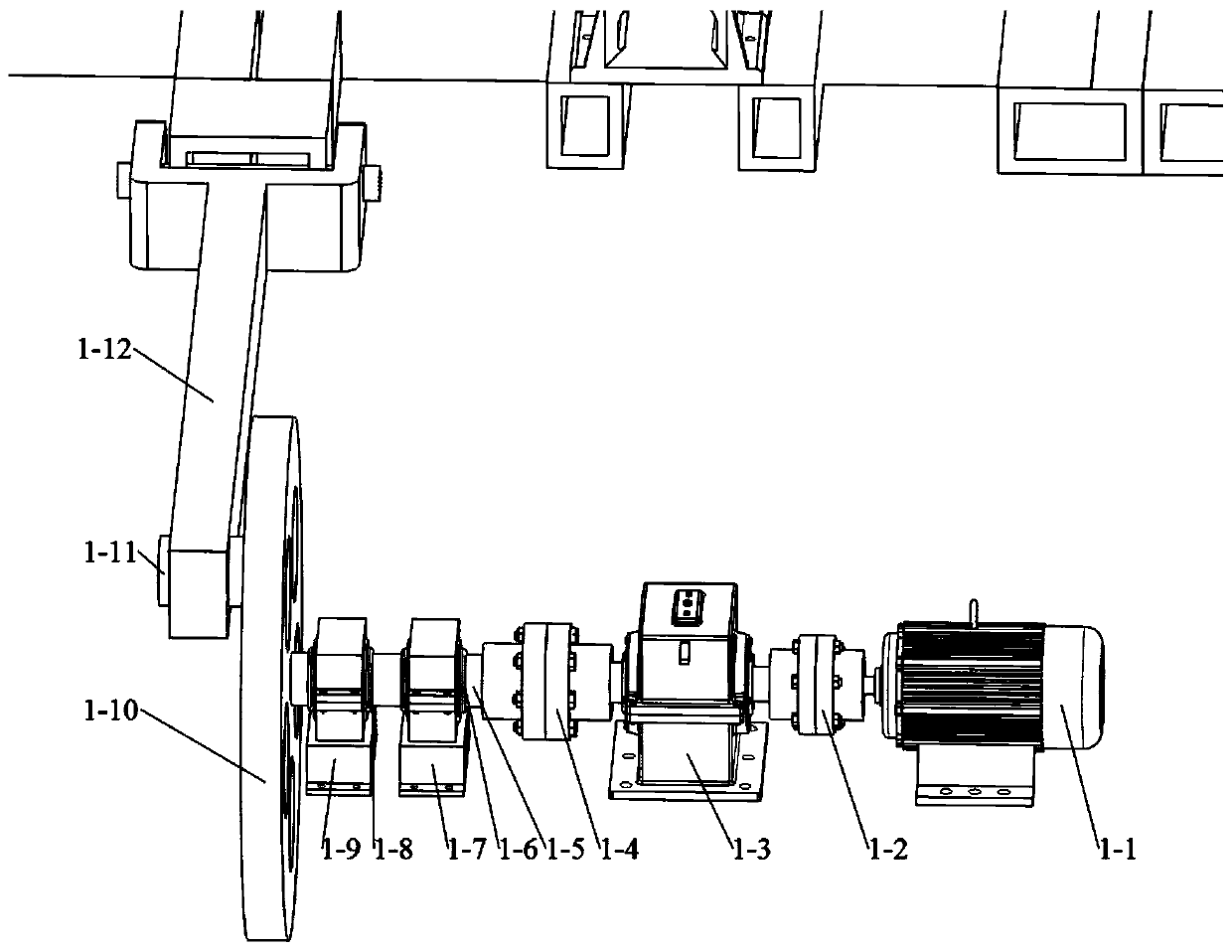

[0026] refer to figure 1 and figure 2 , a new track-gauge bogie track change function and reliability test bench according to the present invention mainly includes a mobile platform power drive device 1, a translational gauge change device 2, a carrying rail 3, a limit device 4, The gantry suspension device 5; the mobile platform power drive device 1 is fixedly installed on the ground, and the longitudinal movement of the translational gauge conversion device 2 is driven by the motor-crank connecting rod motion pair, and the translational gauge conversion device 2 pairs The variable gauge wheelset is unlocked and locked, and provides lateral guidance for the axial gauge variable movement of the wheelset along the wheel shaft; the load-bearing running rail 3 is symmetrically installed under the two sides of the translational gauge changing device 2 , to provide load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com