Outer conductor heating cavity for microwave heating non-combustion equipment

A technology of combustion equipment and microwave heating, applied in applications, smoker supplies, tobacco, etc., can solve the problems of limited transmission distance, large microwave transmission loss, loss of portability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: The present invention is used in the outer conductor heating cavity of microwave heating not to burn equipment

[0061] The implementation mode of this embodiment is as follows:

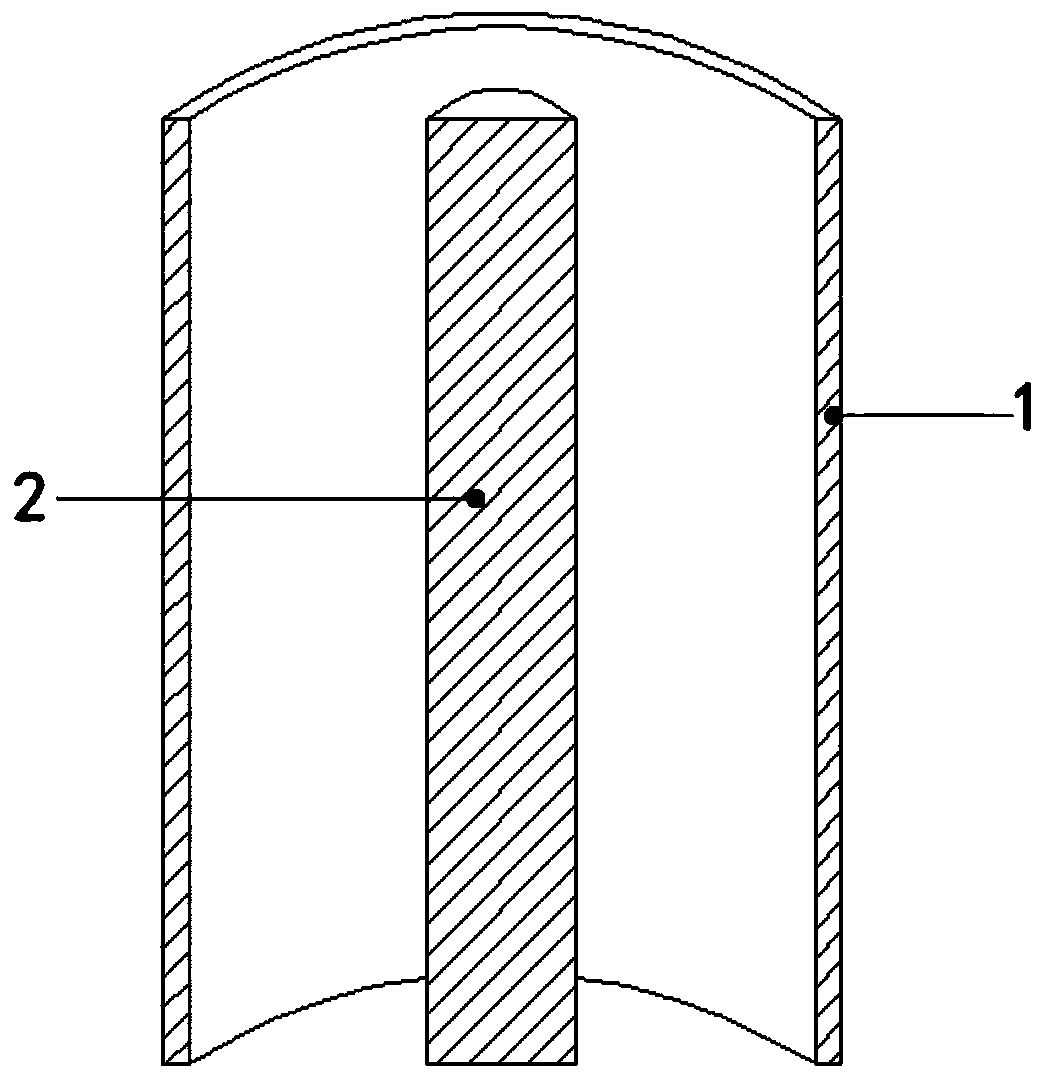

[0062] The outer conductor heating chamber 1 is made of 304 stainless steel material, which is cylindrical and hollow, and its length is longer than that of the inner conductor column 2. The microwave frequency of the solid-state microwave source used is 915MHz.

[0063] Place the outer conductor heating cavity 1 of this embodiment on the periphery of the axis of the inner conductor column 2 of the microwave heating smoking set to obtain a microwave coaxial heating cavity for the microwave heating and non-burning smoking set. For details, refer to the attached figure 1 .

Embodiment 2

[0064] Embodiment 2: The present invention is used in the outer conductor heating cavity of microwave heating not to burn equipment

[0065] The implementation mode of this embodiment is as follows:

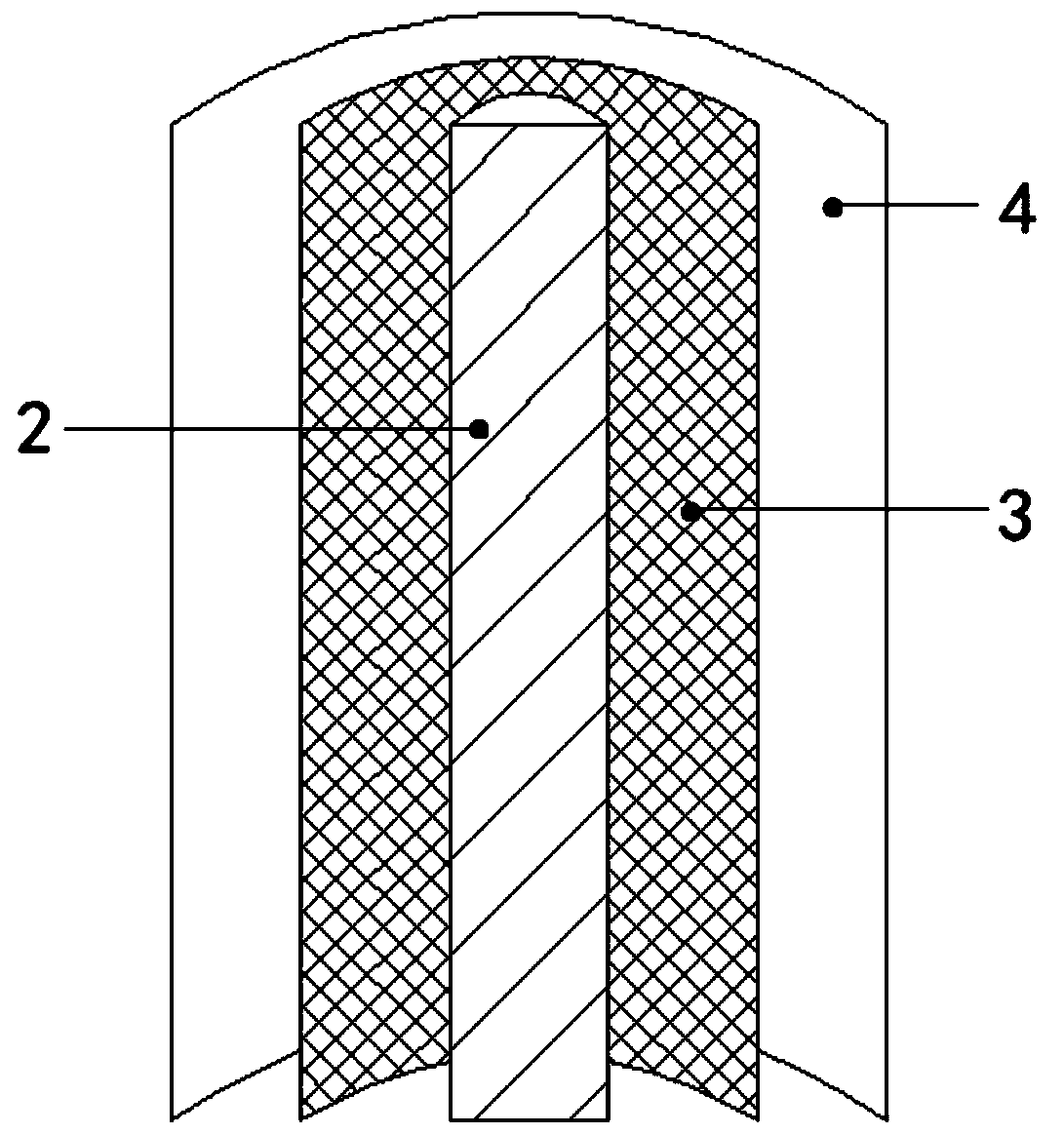

[0066] The outer conductor heating cavity 1 is made of two layers of brass 100-mesh mesh, the diameter of the first layer of outer conductor mesh cavity 3 is slightly smaller than the second layer of outer conductor mesh cavity 4; the outer conductor brass mesh is a cylindrical hollow shape , the length is greater than the length of the inner conductor column 2, and the solid-state microwave source used is 2.45 GHz.

[0067] Place the outer conductor heating cavity 1 of this embodiment on the periphery of the axis of the inner conductor column 2 of the microwave heating smoking set to obtain a microwave coaxial heating cavity for the microwave heating and non-burning smoking set. For details, refer to the attached figure 2 .

Embodiment 3

[0068] Embodiment 3: The present invention is used in the outer conductor heating cavity of microwave heating not to burn equipment

[0069] The implementation mode of this embodiment is as follows:

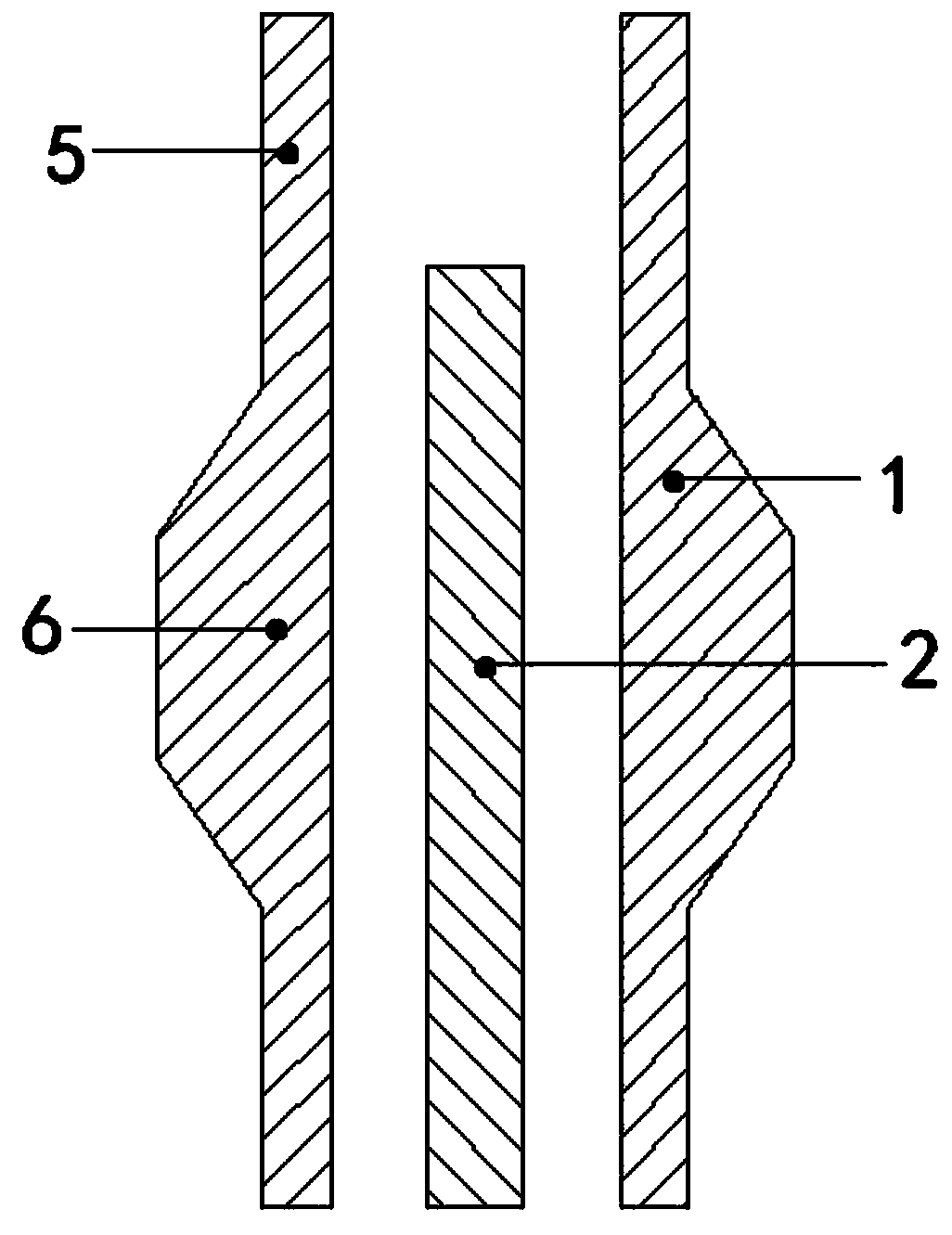

[0070] The outer conductor heating chamber 1 is made of high dielectric constant carbon fiber. The wall thickness of the outer conductor heating chamber 1 is slightly thinner at both ends 5 and the middle part 6 is slightly thicker; the inner wall is a cylindrical hollow shape; the overall length is longer than that of the inner conductor column 2 length, the solid-state microwave source used is 5.8GHz.

[0071] Place the outer conductor heating cavity 1 of this embodiment on the periphery of the axis of the inner conductor column 2 of the microwave heating smoking set to obtain a microwave coaxial heating cavity for the microwave heating and non-burning smoking set. For details, refer to the attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com